Table of Contents

Advantages of Using a Wet Type Drawing Machines For Aluminum Wire

Aluminum wire is a popular choice in various industries due to its lightweight and corrosion-resistant properties. To meet the demand for high-quality aluminum wire, manufacturers rely on drawing machines to reduce the wire’s diameter and improve its mechanical properties. One type of drawing machine commonly used for aluminum wire production is the wet type drawing machine.

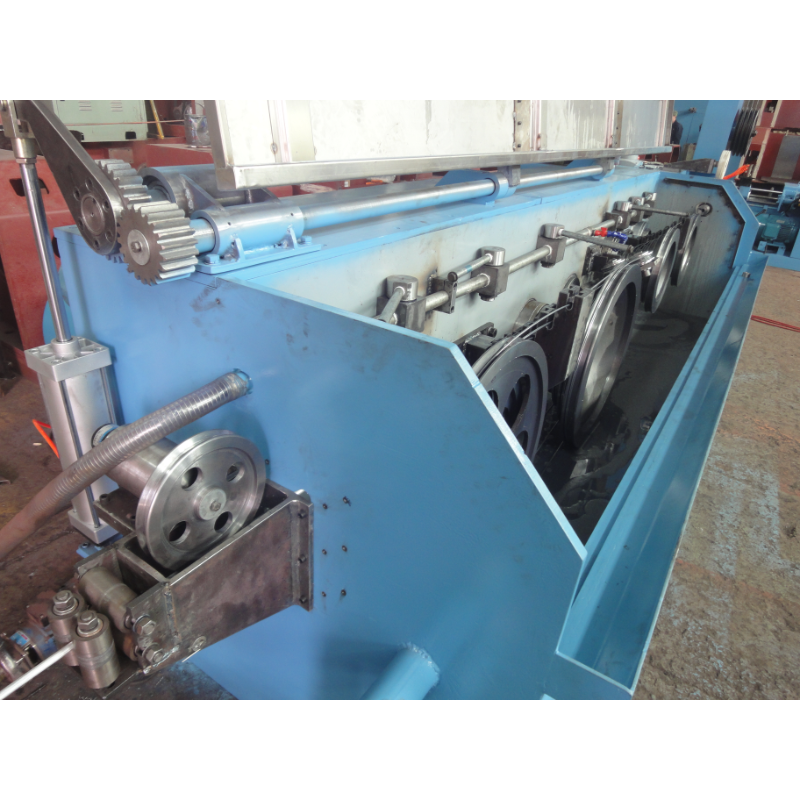

The wet type drawing machine utilizes a lubricant or coolant during the drawing process to reduce friction and heat generation. This results in a smoother surface finish and improved dimensional accuracy of the wire. Additionally, the use of a lubricant helps to extend the tool life and reduce wear on the drawing dies, leading to cost savings for manufacturers.

One of the key advantages of using a wet type Aluminum Fine Wire Drawing Machine is the ability to achieve a high surface quality. The lubricant or coolant used in the drawing process helps to remove any surface defects or impurities, resulting in a clean and smooth finish. This is essential for applications where the appearance of the wire is critical, such as in the production of electrical cables or automotive components.

Furthermore, the use of a wet type drawing machine allows for better control over the drawing process. The lubricant helps to regulate the temperature of the wire, preventing overheating and ensuring consistent drawing conditions. This results in a more uniform wire diameter and mechanical properties, leading to improved product quality and performance.

In addition to surface quality and process control, another advantage of using a wet type drawing machine for aluminum wire is the ability to achieve higher drawing speeds. The lubricant reduces friction between the wire and the drawing dies, allowing for faster drawing rates without compromising the quality of the wire. This increased productivity can help manufacturers meet tight production deadlines and improve overall efficiency.

Moreover, the use of a wet type drawing machine can also lead to energy savings. By reducing friction and heat generation during the drawing process, less energy is required to operate the machine. This not only lowers operating costs but also contributes to a more sustainable manufacturing process.

Overall, the advantages of using a wet type drawing machine for aluminum wire are clear. From improved surface quality and process control to higher drawing speeds and energy savings, this type of drawing machine offers numerous benefits for manufacturers in the aluminum wire industry. By investing in a wet type drawing machine, manufacturers can enhance their production capabilities and deliver high-quality aluminum wire products to meet the demands of their customers.

Maintenance Tips for Wet Type Drawing Machines

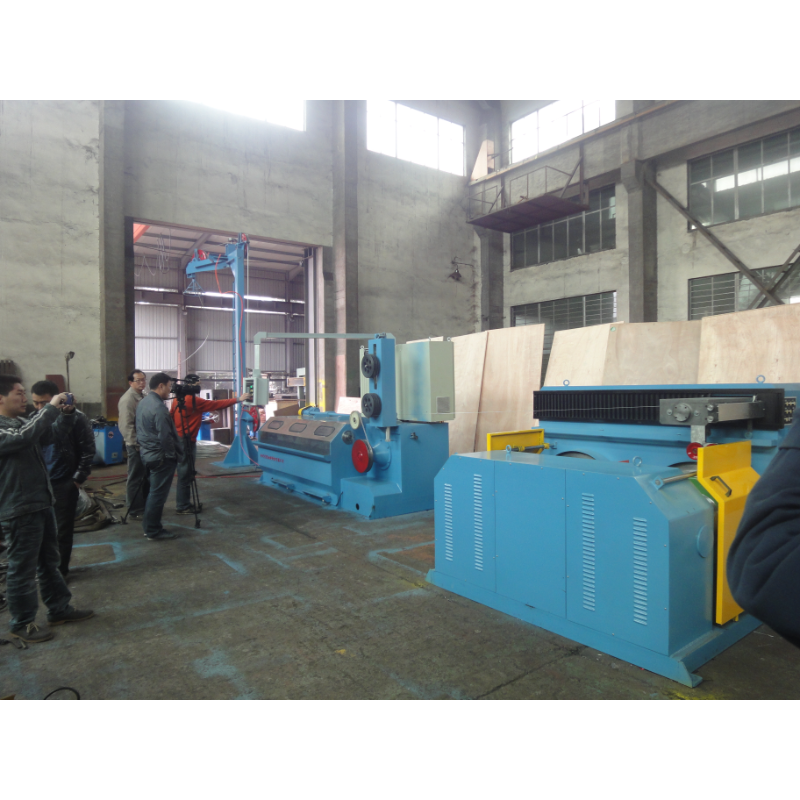

Wet type drawing machines are commonly used in the manufacturing industry to produce aluminum wire. These machines are essential for shaping and reducing the diameter of aluminum rods to create wire of various sizes. However, like any piece of equipment, wet type drawing machines require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tasks for wet type drawing machines is cleaning. Over time, dirt, dust, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. Regularly cleaning the machine with a mild detergent and water can help prevent buildup and keep the machine running smoothly.

In addition to cleaning, it is crucial to regularly inspect the machine for any signs of wear or damage. Check for loose or worn parts, such as belts, pulleys, and bearings, and replace them as needed. Keeping an eye on the machine’s condition can help prevent costly repairs and downtime in the future.

Another important maintenance task for wet type drawing machines is lubrication. Proper lubrication of the machine’s moving parts is essential for reducing friction and preventing wear. Be sure to use the manufacturer’s recommended lubricants and follow the recommended schedule for lubrication to keep the machine running smoothly.

Regularly checking the machine’s coolant system is also crucial for maintaining a Aluminum Alloy Wire Drawing Machine. The coolant system helps regulate the temperature of the machine’s components and prevent overheating. Be sure to check the coolant levels regularly and replace the coolant as needed to ensure proper functioning of the machine.

In addition to these maintenance tasks, it is important to regularly calibrate the machine to ensure accurate wire sizing. Over time, the machine’s calibration can drift, leading to inaccuracies in the wire diameter. Regularly calibrating the machine can help ensure consistent and precise wire sizing.

Proper training of machine operators is also essential for maintaining a wet type drawing machine. Operators should be trained on how to operate the machine safely and efficiently, as well as how to perform basic maintenance tasks. Regular training sessions can help prevent accidents and ensure the machine is being used correctly.

Overall, regular maintenance of a wet type drawing machine is essential for ensuring optimal performance and longevity. By following these maintenance tips, you can help prevent costly repairs and downtime, and keep your machine running smoothly for years to come. Remember to clean the machine regularly, inspect for wear and damage, lubricate moving parts, check the coolant system, calibrate the machine, and provide proper training for operators. By taking care of your wet type drawing machine, you can ensure it continues to produce high-quality aluminum wire for your manufacturing needs.

How to Choose the Right Wet Type Drawing Machine for Aluminum Wire Production

When it comes to producing aluminum wire, choosing the right wet type drawing machine is crucial for achieving high-quality results. Wet type drawing machines are specifically designed to handle the unique properties of aluminum wire, ensuring a smooth and efficient production process. In this article, we will discuss the key factors to consider when selecting a wet type drawing machine for aluminum wire production.

One of the most important factors to consider when choosing an Aluminum Wire Drawing Machine is the size and capacity of the machine. The size of the machine will depend on the volume of aluminum wire you plan to produce, as well as the diameter of the wire. It is important to choose a machine that can handle the specific requirements of your production process, ensuring that you can meet your production goals efficiently.

In addition to size and capacity, it is also important to consider the speed and efficiency of the wet type drawing machine. The speed of the machine will determine how quickly you can produce aluminum wire, while the efficiency of the machine will impact the quality of the finished product. Look for a machine that offers a good balance of speed and efficiency, ensuring that you can produce high-quality aluminum wire in a timely manner.

Another important factor to consider when choosing a wet type drawing machine is the level of automation and control features. Automation can help streamline the production process, reducing the need for manual intervention and improving overall efficiency. Look for a machine that offers advanced automation features, such as automatic wire feeding and tension control, to ensure a smooth and consistent production process.

It is also important to consider the durability and reliability of the wet type drawing machine. Aluminum wire production can be a demanding process, so it is essential to choose a machine that is built to withstand the rigors of continuous use. Look for a machine that is made from high-quality materials and has a reputation for reliability, ensuring that you can rely on it to deliver consistent results over the long term.

When choosing a wet type drawing machine for aluminum wire production, it is also important to consider the level of technical support and service provided by the manufacturer. Look for a manufacturer that offers comprehensive technical support and training, as well as a reliable service network to ensure that you can get assistance quickly if any issues arise. Choosing a reputable manufacturer with a strong track record of customer support can help ensure a smooth and successful production process.

In conclusion, choosing the right wet type drawing machine is essential for achieving high-quality results in aluminum wire production. Consider factors such as size, capacity, speed, efficiency, automation, durability, and technical support when selecting a machine for your production process. By carefully evaluating these factors and choosing a machine that meets your specific requirements, you can ensure a smooth and efficient production process that delivers high-quality aluminum wire.