Benefits of Using Copper Fine Wire Drawing Machine With Annealer

Copper fine wire drawing machines with annealers are essential tools in the manufacturing industry for producing high-quality copper wires. These machines are designed to draw copper wire to smaller diameters while also annealing the wire to improve its ductility and conductivity. The combination of drawing and annealing processes in one machine offers several benefits to manufacturers, making it a popular choice for producing copper wires for various applications.

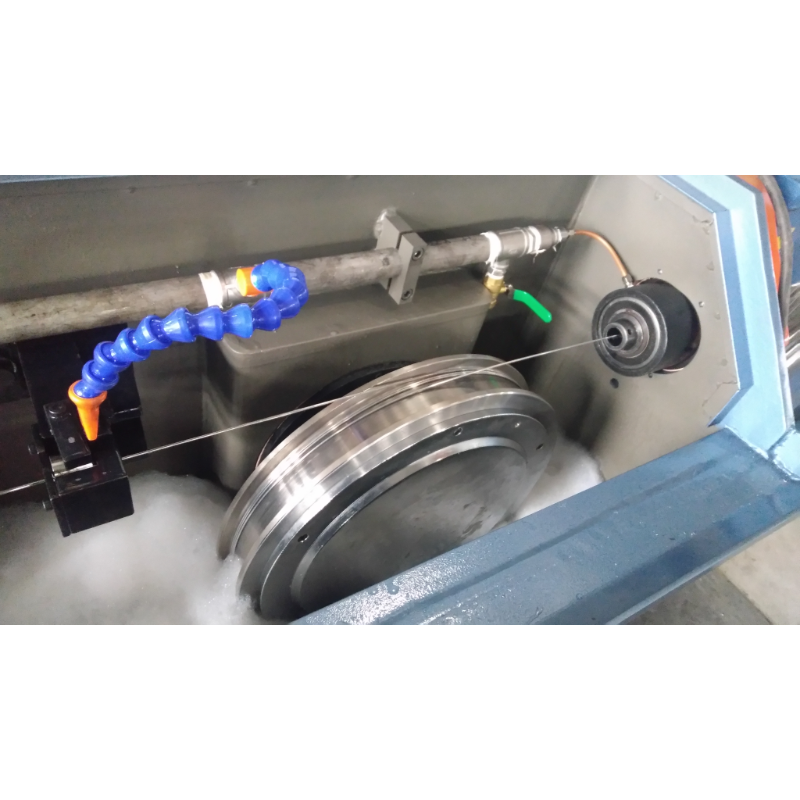

One of the key benefits of using a copper fine wire drawing machine with an annealer is the ability to produce high-quality copper wires with consistent diameter and mechanical properties. The drawing process involves pulling the copper wire through a series of dies to reduce its diameter, while the annealing process involves heating the wire to recrystallize the metal structure and remove any internal stresses. This results in a wire that is not only thinner but also more flexible and durable, making it suitable for a wide range of applications.

Another advantage of using a Copper Wire Drawing Machine with an annealer is the ability to control the speed and tension of the drawing process, which allows manufacturers to produce wires of different diameters and properties. By adjusting the speed and tension of the drawing process, manufacturers can achieve the desired diameter and mechanical properties of the copper wire, making it suitable for specific applications such as electrical wiring, telecommunications, and electronics.

In addition to producing high-quality copper wires, using a copper fine wire drawing machine with an annealer can also help manufacturers reduce production costs and increase efficiency. The combination of drawing and annealing processes in one machine eliminates the need for separate machines and processes, saving time and resources. This not only reduces the overall production costs but also increases the production capacity and output of the manufacturing facility.

Furthermore, the use of a copper fine wire drawing machine with an annealer can also improve the overall quality and performance of the copper wires produced. The annealing process helps to remove any impurities and defects in the copper wire, resulting in a wire that is more uniform and free from defects. This not only improves the electrical conductivity of the wire but also enhances its mechanical properties, making it more reliable and durable for various applications.

Overall, the benefits of using a copper fine wire drawing machine with an annealer are numerous, making it an essential tool for manufacturers in the copper wire industry. From producing high-quality copper wires with consistent diameter and mechanical properties to reducing production costs and increasing efficiency, these machines offer a wide range of advantages that can help manufacturers meet the growing demand for copper wires in various industries. By investing in a copper fine wire drawing machine with an annealer, manufacturers can improve the quality, performance, and efficiency of their production processes, ultimately leading to greater success and competitiveness in the market.