Table of Contents

How to Choose the Right Aluminum Alloy Wire Drawing Machine for Your Business

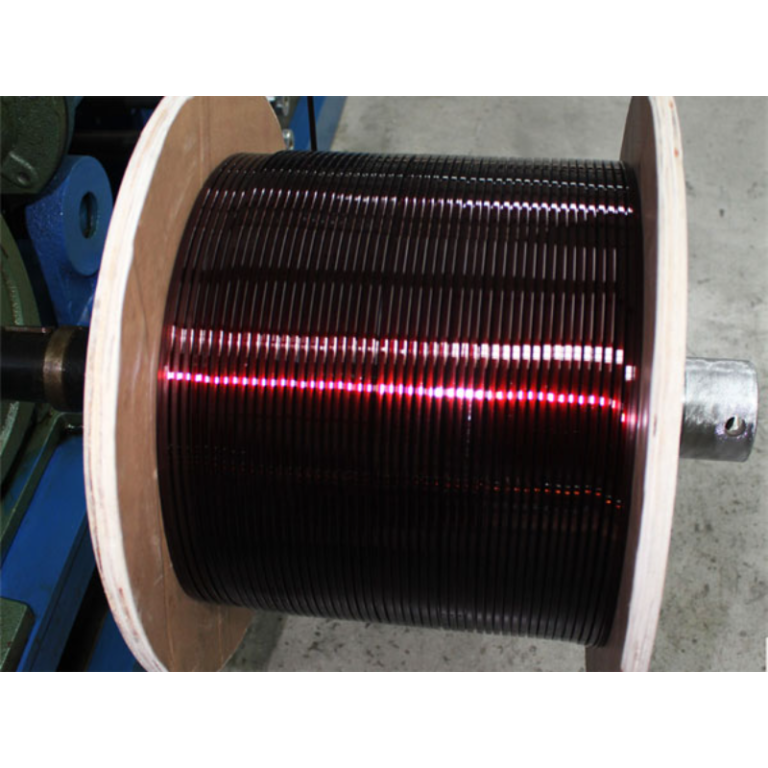

Aluminum alloy wire drawing machines are essential equipment for businesses involved in the production of aluminum wires. These machines are used to reduce the diameter of aluminum rods or wires by pulling them through a series of dies, resulting in a smoother surface finish and improved mechanical properties. Choosing the right aluminum alloy wire drawing machine for your business is crucial to ensure efficient production and high-quality output.

When selecting an aluminum alloy wire drawing machine, there are several factors to consider. The first consideration is the type of aluminum alloy you will be working with. Different alloys have varying properties, such as hardness and ductility, which can affect the performance of the wire drawing machine. It is important to choose a machine that is compatible with the specific alloy you will be using to ensure optimal results.

Another important factor to consider is the size and capacity of the wire drawing machine. The size of the machine should be suitable for the diameter of the aluminum wires you will be producing. Additionally, the machine should have the capacity to handle the volume of production required for your business. It is important to choose a machine that can meet your production needs without being overworked, as this can lead to decreased efficiency and increased maintenance costs.

The speed and efficiency of the wire drawing machine are also important considerations. A machine that can operate at higher speeds will allow for increased production output, leading to higher efficiency and profitability for your business. Additionally, a machine with advanced features such as automatic lubrication systems and digital controls can help improve the overall performance and reliability of the machine.

Durability and reliability are key factors to consider when choosing an Aluminum Wire Breakdown Machine. The machine should be made of high-quality materials and components to ensure long-term durability and minimal downtime. It is important to choose a machine from a reputable manufacturer with a track record of producing reliable and high-quality equipment.

Cost is another important consideration when selecting an aluminum alloy wire drawing machine for your business. While it is important to invest in a high-quality machine that meets your production needs, it is also important to consider the overall cost of the machine, including maintenance and operating costs. It is important to weigh the initial investment against the long-term benefits and savings that a high-quality machine can provide.

In conclusion, choosing the right aluminum alloy wire drawing machine for your business is a crucial decision that can impact the efficiency and profitability of your production process. By considering factors such as the type of alloy, size and capacity, speed and efficiency, durability and reliability, and cost, you can select a machine that meets your production needs and provides long-term value for your business. Investing in a high-quality aluminum alloy wire drawing machine can help improve the quality of your aluminum wires and enhance the overall performance of your production process.

Maintenance Tips for Aluminum Alloy Wire Drawing Machine

Aluminum alloy wire drawing machines are essential equipment in the manufacturing industry, used to produce wires of various diameters and lengths. To ensure the smooth operation and longevity of these machines, regular maintenance is crucial. In this article, we will discuss some maintenance tips for aluminum alloy wire drawing machines.

First and foremost, it is important to keep the machine clean and free of debris. Dust, dirt, and other particles can accumulate on the machine’s components, leading to increased friction and wear. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues and prolong the machine’s lifespan.

In addition to cleaning, lubrication is another key aspect of maintenance for Aluminum Wire Intermediate Drawing Machine. Proper lubrication of the machine’s moving parts, such as bearings and gears, can reduce friction and prevent premature wear. It is important to use the correct type of lubricant recommended by the manufacturer and to apply it regularly according to the machine’s maintenance schedule.

Regular inspection of the machine’s components is also essential to identify any potential issues before they escalate. Check for signs of wear, damage, or misalignment, and address any issues promptly to prevent further damage to the machine. It is recommended to create a maintenance checklist and schedule regular inspections to ensure the machine is in optimal condition.

Another important maintenance tip for aluminum alloy wire drawing machines is to monitor the machine’s operating temperature. Overheating can cause damage to the machine’s components and affect its performance. Ensure that the machine is properly ventilated and that cooling systems are functioning effectively to prevent overheating.

Furthermore, it is important to calibrate the machine regularly to ensure accurate wire diameter and quality. Improper calibration can result in inconsistent wire thickness and quality, affecting the final product. Follow the manufacturer’s guidelines for calibration and make adjustments as needed to maintain the machine’s performance.

Lastly, training and educating operators on proper machine maintenance and operation is crucial for the longevity of aluminum alloy wire drawing machines. Ensure that operators are familiar with the machine’s maintenance requirements and procedures, and provide training on best practices for operating the machine safely and efficiently.

In conclusion, regular maintenance is essential for the optimal performance and longevity of aluminum alloy wire drawing machines. By following these maintenance tips, you can ensure that your machine operates smoothly and efficiently, producing high-quality wires for your manufacturing needs. Remember to clean the machine regularly, lubricate moving parts, inspect components, monitor operating temperature, calibrate the machine, and provide training to operators. By taking these steps, you can extend the life of your aluminum alloy wire drawing machine and maximize its productivity.