Table of Contents

How to Choose the Right Aluminum Wire Drawing Machine for Your Needs

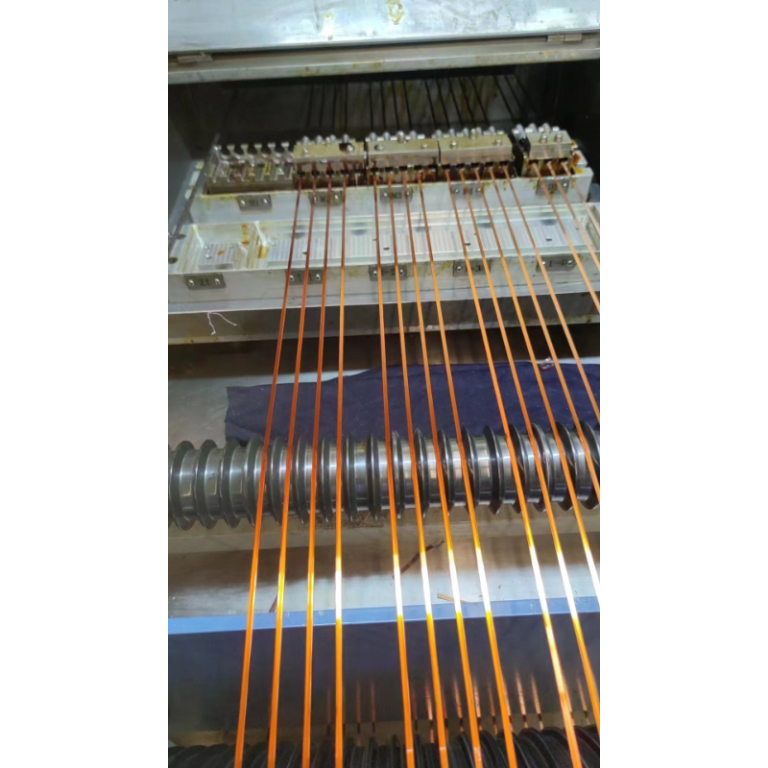

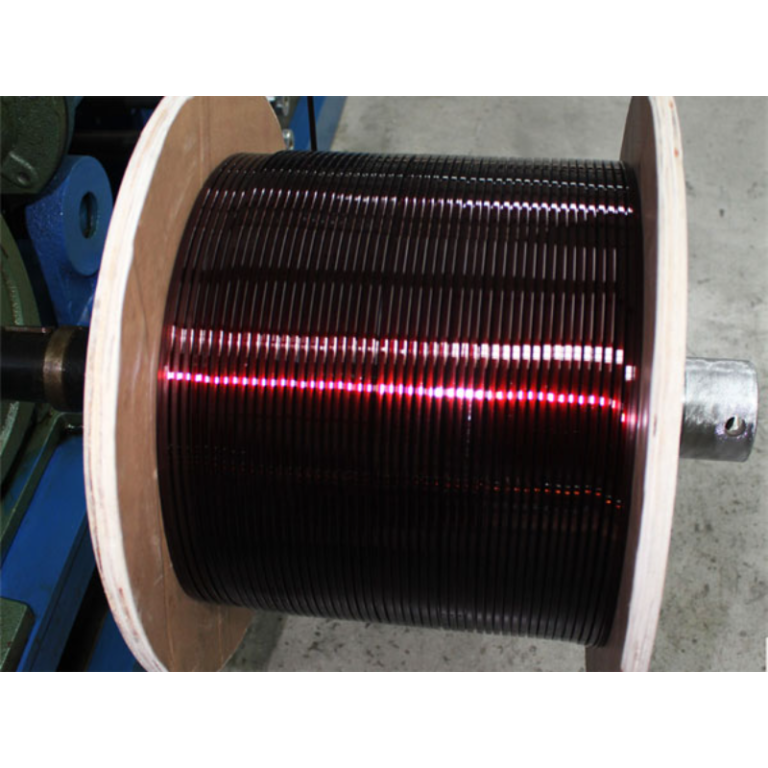

Aluminum wire drawing machines are essential equipment for industries that require the production of aluminum wires of various diameters. These machines are used to reduce the diameter of aluminum rods or wires by pulling them through a series of dies, resulting in a smoother surface finish and improved mechanical properties. Choosing the right Automatic Aluminum wire drawing machine for your specific needs is crucial to ensure optimal performance and efficiency in your production process.

When selecting an aluminum wire drawing machine, there are several factors to consider. The first consideration is the diameter range of the wires you need to produce. Different machines are designed to handle different diameter ranges, so it is important to choose a machine that can accommodate the specific sizes you require. Additionally, consider the speed at which you need to produce the wires, as this will determine the capacity and power requirements of the machine.

Another important factor to consider is the number of dies in the machine. The number of dies will determine the number of passes the wire needs to make through the machine to achieve the desired diameter. Machines with more dies can produce wires with smaller diameters in fewer passes, resulting in higher efficiency and productivity. However, machines with more dies may also be more complex and require more maintenance.

It is also important to consider the material of the dies in the machine. Dies are typically made of materials such as tungsten carbide or diamond, which are highly wear-resistant and can withstand the high pressures and temperatures involved in the wire drawing process. Choosing a machine with high-quality dies will ensure a longer lifespan and better performance of the machine.

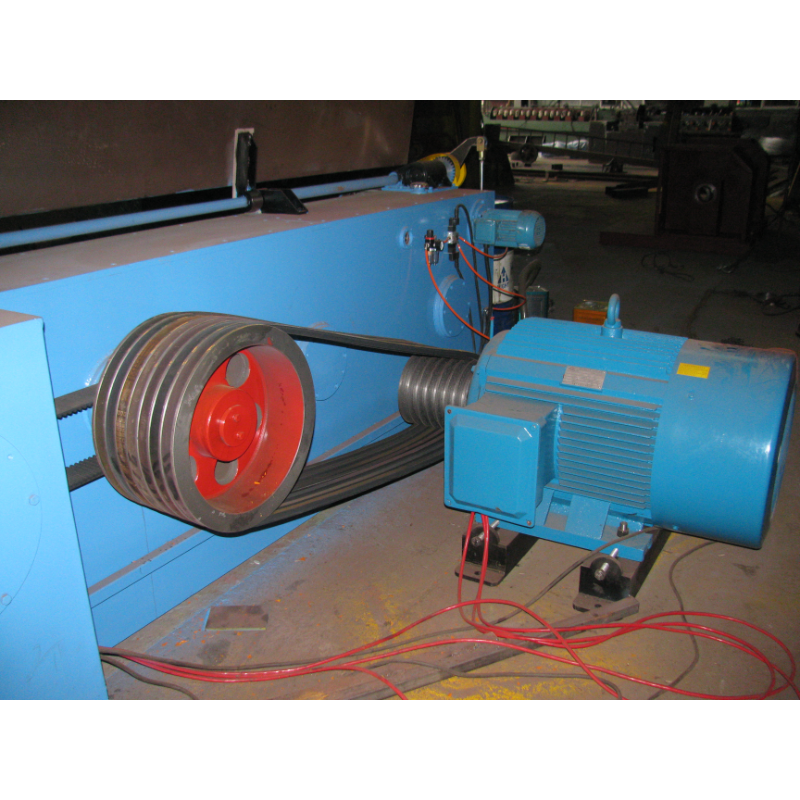

Additionally, consider the type of drive system used in the machine. There are two main types of drive systems used in wire drawing machines: direct drive and gear drive. Direct drive systems are more efficient and require less maintenance, but they may be more expensive upfront. Gear drive systems, on the other hand, are more cost-effective but may require more maintenance over time. Choose a drive system that best suits your budget and maintenance requirements.

When selecting an aluminum wire drawing machine, it is also important to consider the overall build quality and reliability of the machine. Look for machines from reputable manufacturers with a track record of producing high-quality equipment. Consider factors such as the machine’s construction, components, and overall design to ensure that it is durable and reliable for long-term use.

In conclusion, choosing the right aluminum wire drawing machine for your specific needs requires careful consideration of factors such as diameter range, speed, number of dies, die material, drive system, and overall build quality. By taking these factors into account and selecting a machine from a reputable manufacturer, you can ensure optimal performance and efficiency in your wire drawing process. Investing in a high-quality aluminum wire drawing machine will ultimately save you time and money in the long run, making it a worthwhile investment for your business.

Maintenance Tips for Aluminum Wire Drawing Machines

Aluminum wire drawing machines are essential equipment in the manufacturing industry, used to produce aluminum wires of various diameters for a wide range of applications. These machines are complex pieces of machinery that require regular maintenance to ensure optimal performance and longevity. In this article, we will discuss some maintenance tips for aluminum wire drawing machines to help you keep your equipment in top condition.

One of the most important maintenance tasks for Aluminum Alloy Wire Drawing Machine is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. This can result in decreased efficiency and potential damage to the machine. To prevent this, it is essential to clean the machine regularly using a soft brush or cloth to remove any buildup.

In addition to cleaning, lubrication is another crucial aspect of maintaining aluminum wire drawing machines. Proper lubrication helps reduce friction between moving parts, preventing premature wear and extending the machine’s lifespan. It is important to use the correct type of lubricant recommended by the manufacturer and to apply it to all moving parts regularly.

Inspecting the machine for signs of wear and damage is also essential for proper maintenance. Check for loose or damaged components, such as belts, pulleys, and bearings, and replace them as needed. Regular inspections can help identify potential issues before they escalate into more significant problems, saving you time and money in the long run.

Another important maintenance tip for aluminum wire drawing machines is to monitor the machine’s operating temperature. Overheating can cause damage to the machine’s components and affect its performance. Make sure the machine is operating within the recommended temperature range and take steps to cool it down if necessary, such as increasing ventilation or reducing the load on the machine.

Regular calibration of the machine is also crucial for maintaining its accuracy and efficiency. Over time, the machine’s settings may drift, leading to inaccuracies in wire diameter and quality. Calibrating the machine regularly ensures that it is producing wires within the specified tolerances and helps prevent costly rework or scrap.

Lastly, it is essential to train your operators on proper machine maintenance procedures. Make sure they understand the importance of regular cleaning, lubrication, inspection, and calibration, and provide them with the necessary tools and resources to perform these tasks effectively. Proper training can help prevent accidents, reduce downtime, and prolong the life of your aluminum wire drawing machine.

In conclusion, proper maintenance is key to keeping your aluminum wire drawing machine in top condition. By following these maintenance tips, you can ensure that your machine operates efficiently, produces high-quality wires, and lasts for years to come. Remember to clean the machine regularly, lubricate moving parts, inspect for wear and damage, monitor operating temperature, calibrate the machine, and train your operators on proper maintenance procedures. With proper care and attention, your aluminum wire drawing machine will continue to be a valuable asset to your manufacturing operation.