Benefits of Using a Vertical Enameling Machine Oven Circulation System

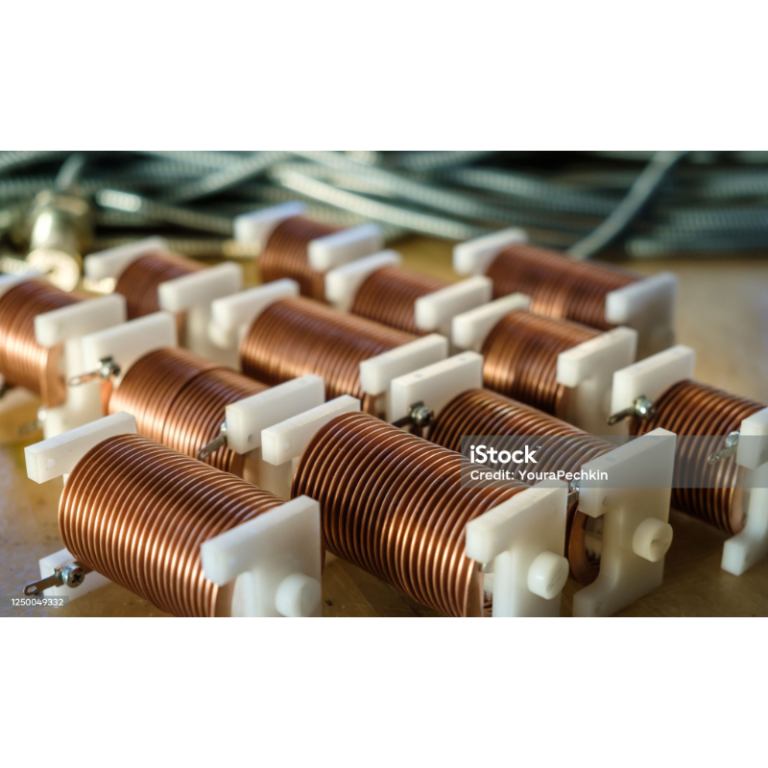

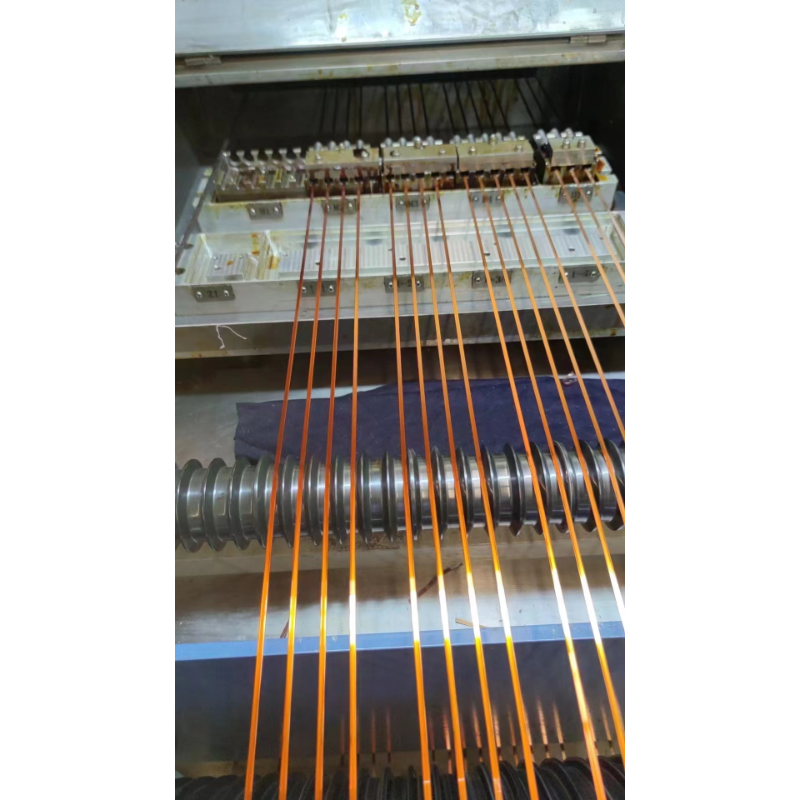

Enameling is a process that involves applying a protective coating to metal surfaces to enhance their durability and appearance. One of the key components in the enameling process is the oven circulation system, which plays a crucial role in ensuring that the enamel coating is applied evenly and effectively. In this article, we will explore the benefits of using a vertical enameling machine oven circulation system.

One of the primary advantages of a vertical enameling machine oven circulation system is its ability to provide consistent and uniform heat distribution throughout the oven chamber. This is essential for achieving a high-quality enamel coating, as uneven heat distribution can result in inconsistencies in the coating thickness and appearance. By circulating hot air evenly throughout the oven chamber, a vertical enameling machine oven circulation system helps to ensure that the enamel coating is applied uniformly to the metal surface, resulting in a smooth and flawless finish.

In addition to providing consistent heat distribution, a vertical enameling machine oven circulation system also helps to improve the efficiency of the enameling process. By circulating hot air throughout the oven chamber, the system helps to reduce the amount of time required to cure the enamel coating, allowing for faster production times and increased productivity. This can be particularly beneficial for manufacturers who need to produce large quantities of enameled products in a short amount of time.

Another key benefit of using a vertical enameling machine oven circulation system is its ability to reduce energy consumption. By circulating hot air throughout the oven chamber, the system helps to maintain a consistent temperature, reducing the need for excessive heating and cooling cycles. This not only helps to lower energy costs but also helps to reduce the environmental impact of the enameling process. Additionally, by reducing the amount of time required to cure the enamel coating, the system helps to further decrease energy consumption, making it a more sustainable option for manufacturers.

Furthermore, a vertical enameling machine oven circulation system can help to improve the overall quality of the enamel coating. By providing consistent heat distribution and reducing curing times, the system helps to ensure that the enamel coating is applied evenly and effectively, resulting in a high-quality finish. This can be particularly important for manufacturers who produce enameled products for high-end markets, where quality and consistency are paramount.

Overall, the benefits of using a vertical enameling machine oven circulation system are clear. From providing consistent heat distribution and improving efficiency to reducing energy consumption and enhancing the quality of the enamel coating, the system offers a range of advantages for manufacturers looking to enhance their enameling process. By investing in a vertical enameling machine oven circulation system, manufacturers can improve their production processes, increase productivity, and achieve superior results in their enameled products.