Exploring of Using Aluminum Wire Drawing Machine in the Production Line

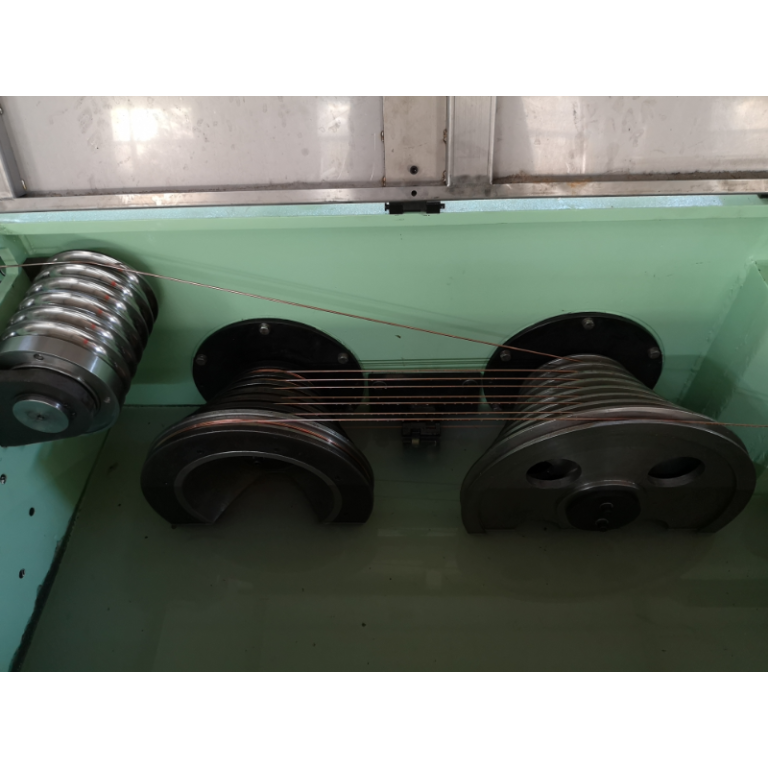

Aluminum wire drawing production lines are essential in the manufacturing industry for producing high-quality aluminum wire products. The process involves pulling aluminum wire through a series of dies to reduce its diameter and improve its mechanical properties. There are several benefits to using aluminum wire in the production line, making it a popular choice for various applications.

One of the main advantages of using aluminum wire is its lightweight nature. Aluminum is significantly lighter than other metals such as copper, making it an ideal choice for applications where weight is a concern. This makes aluminum wire drawing production lines suitable for industries such as aerospace, automotive, and electronics, where weight reduction is crucial for improving fuel efficiency and overall performance.

In addition to its lightweight properties, aluminum wire is also highly conductive. This makes it an excellent choice for electrical applications where high conductivity is required. Aluminum wire drawing production lines can produce aluminum wire with excellent electrical conductivity, making it suitable for use in power transmission lines, electrical wiring, and other electrical components.

Another benefit of using aluminum wire in the production line is its corrosion resistance. Aluminum has a natural oxide layer that forms on its surface, providing protection against corrosion and rust. This makes aluminum wire ideal for outdoor applications where exposure to moisture and harsh environmental conditions is a concern. Aluminum Alloy Wire Drawing Machine can produce aluminum wire with enhanced corrosion resistance, making it a durable and long-lasting material for various applications.

Furthermore, aluminum wire is highly malleable and ductile, allowing it to be easily formed and shaped into different configurations. Aluminum wire drawing production lines can produce aluminum wire in various sizes and shapes to meet the specific requirements of different applications. This flexibility in design makes aluminum wire a versatile material for a wide range of industries, including construction, automotive, and telecommunications.

Additionally, aluminum wire is cost-effective compared to other metals such as copper. Aluminum is abundant and widely available, making it a more affordable option for manufacturers looking to reduce production costs. Aluminum wire drawing production lines can produce aluminum wire at a lower cost, making it an attractive choice for businesses looking to improve their bottom line without compromising on quality.

In conclusion, the benefits of using aluminum wire in the production line are numerous. From its lightweight and conductive properties to its corrosion resistance and cost-effectiveness, aluminum wire is a versatile material that is suitable for a wide range of applications. Aluminum wire drawing production lines play a crucial role in manufacturing high-quality aluminum wire products that meet the specific requirements of different industries. As technology continues to advance, the demand for aluminum wire is expected to grow, making it an essential material for the future of manufacturing.