Table of Contents

How to Choose the Right Horizontal Enameling Machine Manufacturer for Your Business

When it comes to choosing the right horizontal enameling machine manufacturer for your business, there are several factors to consider. The quality of the machines, the reputation of the manufacturer, and the level of customer service are all important aspects to take into account. In this article, we will discuss these factors in more detail to help you make an informed decision.

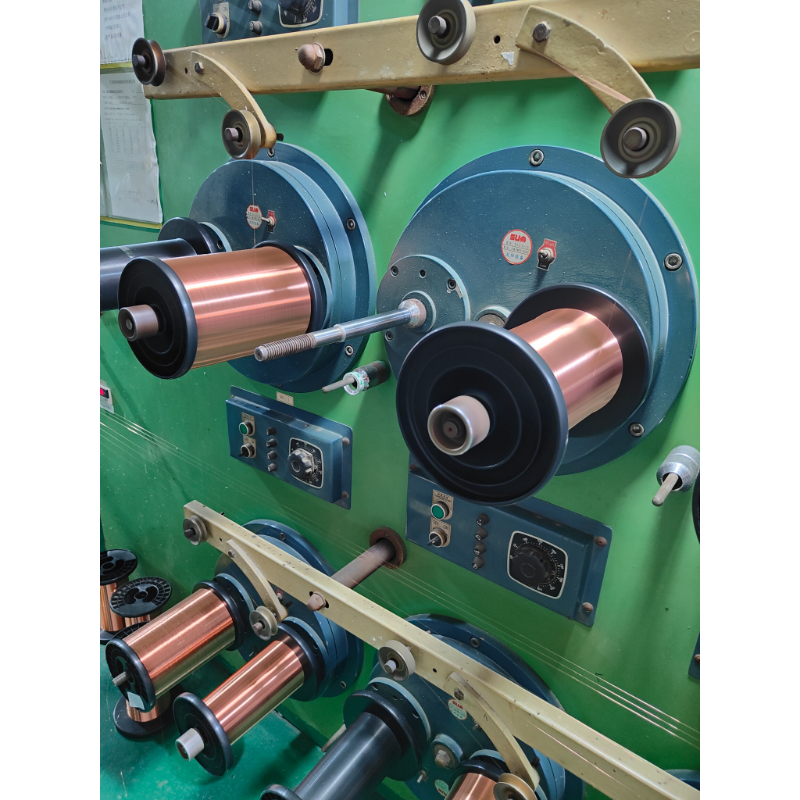

First and foremost, the quality of the machines produced by the manufacturer is crucial. You want to ensure that the machines you purchase are durable, reliable, and efficient. Look for a manufacturer that uses high-quality materials and state-of-the-art technology in the production of their machines. This will help ensure that you get a product that meets your needs and will last for years to come.

Another important factor to consider is the reputation of the manufacturer. Do some research to find out what other customers have to say about their experience with the manufacturer. Look for reviews and testimonials online, and ask for references from the manufacturer themselves. A manufacturer with a good reputation is more likely to provide you with a high-quality product and excellent customer service.

Speaking of customer service, this is another key factor to consider when choosing a Wire Enameling Plant manufacturer. You want to work with a manufacturer that is responsive, helpful, and easy to communicate with. Look for a manufacturer that offers technical support, training, and maintenance services to help you get the most out of your machines. A manufacturer that is committed to customer satisfaction will be a valuable partner for your business.

In addition to these factors, you should also consider the cost of the machines and the manufacturer’s payment terms. Compare prices from different manufacturers to ensure that you are getting a competitive rate. Be sure to ask about any additional fees or charges that may apply, and make sure you understand the payment terms before making a purchase. It is important to find a manufacturer that offers a fair price for their machines and is transparent about their pricing.

When choosing a horizontal enameling machine manufacturer, it is also important to consider the manufacturer’s experience and expertise in the industry. Look for a manufacturer that has been in business for a number of years and has a proven track record of success. An experienced manufacturer is more likely to have the knowledge and skills necessary to produce high-quality machines that meet your specific requirements.

In conclusion, choosing the right horizontal enameling machine manufacturer for your business is a decision that should not be taken lightly. Consider factors such as the quality of the machines, the reputation of the manufacturer, customer service, cost, and experience when making your decision. By taking the time to research and evaluate different manufacturers, you can find a partner that will provide you with high-quality machines and excellent service for years to come.

Benefits of Investing in a Horizontal Enameling Machine for Industrial Applications

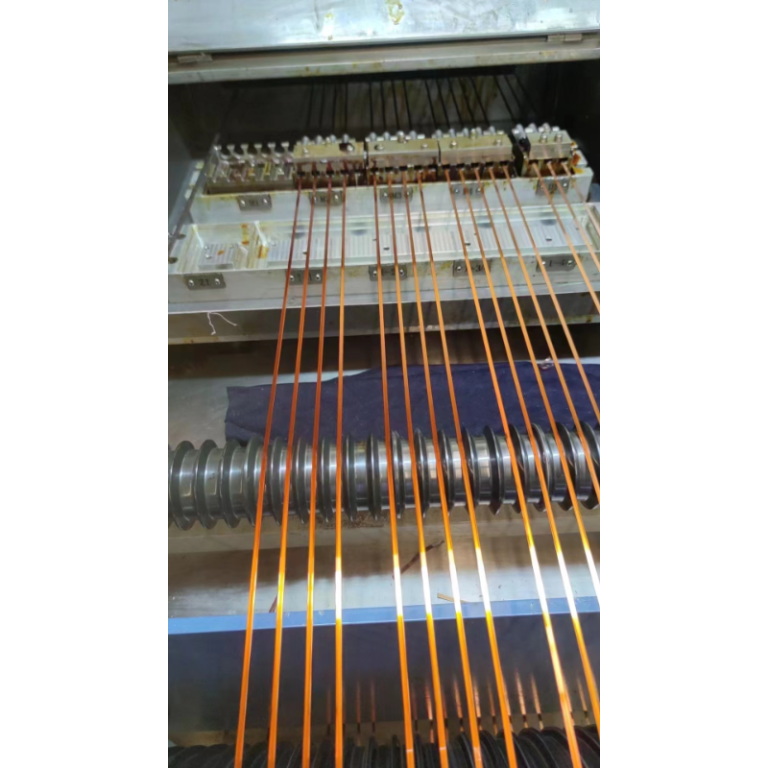

Enameling is a process that involves applying a protective coating to metal surfaces to enhance their durability and appearance. In industrial applications, enameling is commonly used to protect metal components from corrosion, abrasion, and other forms of wear and tear. One of the key pieces of equipment used in the enameling process is a horizontal enameling machine.

Horizontal enameling machines are designed to apply enamel coatings to metal surfaces in a precise and efficient manner. These machines are typically used in large-scale industrial operations where high volumes of metal components need to be coated quickly and consistently. By investing in a horizontal enameling machine, manufacturers can benefit from increased productivity, improved product quality, and reduced operating costs.

One of the primary benefits of using a horizontal enameling machine is its ability to apply enamel coatings evenly and consistently across a wide range of metal surfaces. This ensures that the coated components have a uniform appearance and are protected from corrosion and other forms of damage. In addition, horizontal enameling machines can be programmed to apply multiple layers of enamel to achieve the desired level of protection and finish.

Another advantage of investing in a horizontal enameling machine is the increase in productivity that it can provide. These machines are capable of coating metal components at a much faster rate than manual methods, allowing manufacturers to meet production deadlines and fulfill customer orders more efficiently. Additionally, horizontal enameling machines require minimal operator intervention, freeing up workers to focus on other tasks and increasing overall production capacity.

In addition to improving productivity and product quality, investing in a horizontal enameling machine can also lead to cost savings for manufacturers. By automating the enameling process, companies can reduce labor costs and minimize material waste, resulting in lower operating expenses and higher profit margins. Furthermore, the consistent application of enamel coatings provided by horizontal enameling machines can help to reduce the need for rework and repairs, further lowering production costs.

Overall, investing in a horizontal enameling machine can provide a wide range of benefits for manufacturers in various industries. From increased productivity and improved product quality to cost savings and operational efficiency, these machines offer a valuable solution for companies looking to enhance their enameling processes. By incorporating a horizontal enameling machine into their operations, manufacturers can achieve higher levels of performance and competitiveness in the market.

In conclusion, horizontal enameling machines play a crucial role in the industrial enameling process, offering numerous benefits for manufacturers seeking to enhance their production capabilities. By investing in a horizontal enameling machine, companies can improve productivity, product quality, and cost efficiency, ultimately leading to greater success in the competitive marketplace. With their ability to apply enamel coatings evenly and consistently, horizontal enameling machines are a valuable asset for any industrial operation looking to achieve optimal results in metal surface protection and enhancement.