Table of Contents

Step-by-Step Guide to Copper Wire Drawing Machine Process

Copper wire drawing is a process used to reduce the diameter of a copper wire by pulling it through a series of dies. This process is essential for producing copper wires of various sizes and gauges, which are used in a wide range of applications, including electrical wiring, telecommunications, and construction. The copper wire drawing machine is the key equipment used in this process, and understanding how it works is crucial for achieving high-quality copper wires.

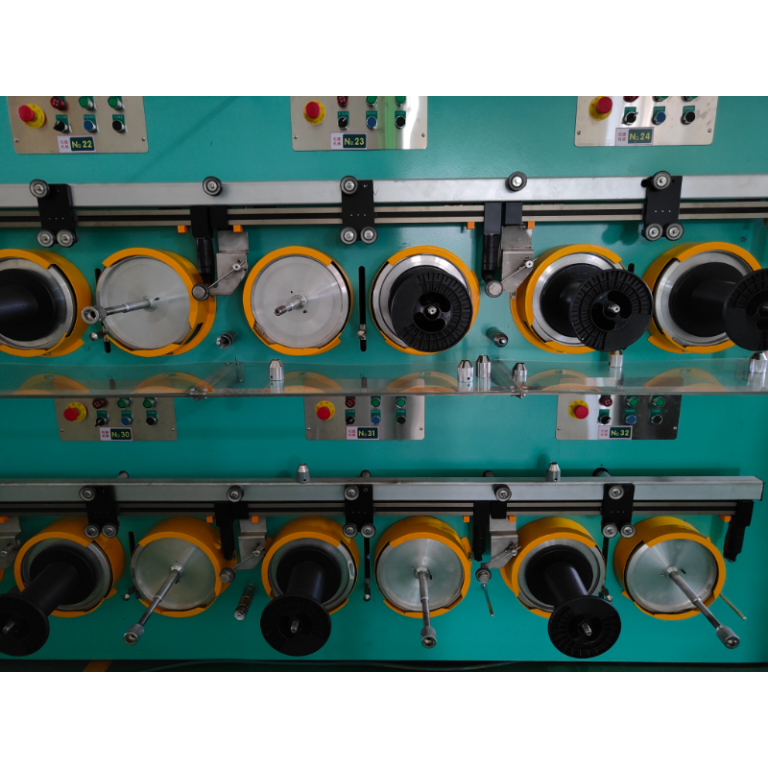

The copper wire drawing machine process begins with a spool of copper wire being loaded onto the machine. The wire is then fed through a series of dies, which are progressively smaller in diameter. As the wire passes through each die, it is pulled by a set of rotating capstans, which help to reduce its diameter. The process is repeated multiple times until the desired wire gauge is achieved.

One of the key components of the copper wire drawing machine is the drawing die. Drawing dies are typically made of tungsten carbide or diamond, which are extremely hard materials that can withstand the high pressures and temperatures generated during the wire drawing process. The die is mounted in a die holder, which is attached to the machine and guides the wire through the drawing process.

Another important component of the copper wire drawing machine is the capstan. Capstans are rotating drums that are used to pull the wire through the drawing dies. The speed and tension of the capstans can be adjusted to control the rate at which the wire is drawn, as well as the amount of reduction in diameter. This is crucial for achieving the desired wire gauge and quality.

In addition to the drawing dies and capstans, the copper wire drawing machine also includes a lubrication system. Lubricants are used to reduce friction between the wire and the drawing dies, which helps to prevent the wire from breaking or becoming damaged during the drawing process. The lubrication system is typically automated and can be adjusted to ensure optimal performance.

As the wire passes through the drawing dies, it undergoes a process known as work hardening. Work hardening is a phenomenon in which the wire becomes harder and more brittle as it is drawn through the dies. To prevent the wire from becoming too brittle, it is important to anneal the wire periodically. Annealing involves heating the wire to a high temperature and then allowing it to cool slowly, which helps to restore its ductility and flexibility.

Once the wire has been drawn to the desired gauge, it is wound onto a spool or reel for further processing. The finished copper wire can then be used in a variety of applications, including electrical wiring, telecommunications, and construction.

In conclusion, the Copper Fine Wire Drawing Machine With Annealer process is a critical step in the production of high-quality copper wires. By understanding how the machine works and the various components involved, manufacturers can ensure that they produce copper wires that meet the required specifications and standards. With the right equipment and expertise, copper wire drawing can be a highly efficient and cost-effective process for producing high-quality copper wires.

Benefits of Using Copper Wire Drawing Machine Process

Copper wire drawing is a process that involves pulling a copper rod through a series of dies to reduce its diameter and increase its length. This process is commonly used in the manufacturing of electrical wires, cables, and other copper products. One of the key benefits of using a copper wire drawing machine is the ability to produce high-quality copper wire with consistent diameter and surface finish.

The copper wire drawing machine process begins with a copper rod that is fed into the machine. The rod is then passed through a series of dies, each with a slightly smaller diameter than the previous one. As the rod is pulled through the dies, it is stretched and reduced in diameter, resulting in a longer and thinner wire. This process can be repeated multiple times to achieve the desired wire diameter.

One of the main advantages of using a copper wire drawing machine is the ability to control the diameter of the wire with precision. This is important in industries where the wire must meet specific size requirements for proper functioning. By using a wire drawing machine, manufacturers can produce wire with consistent diameter and tolerance, ensuring that it meets the necessary specifications.

In addition to controlling the diameter of the wire, the wire drawing process also improves the surface finish of the copper wire. As the wire is pulled through the dies, any imperfections or surface irregularities are smoothed out, resulting in a clean and uniform surface. This is important for applications where the wire will be exposed to high temperatures or corrosive environments, as a smooth surface can help prevent damage and ensure the longevity of the wire.

Another benefit of using a Copper Wire Drawing Machine for Rod Breakdown Machine is the ability to increase the length of the wire. By stretching the copper rod through the dies, manufacturers can produce longer lengths of wire without the need for additional splicing or welding. This can be particularly useful in applications where long lengths of wire are required, such as in the construction of electrical grids or telecommunications networks.

Furthermore, the wire drawing process can also improve the mechanical properties of the copper wire. As the wire is stretched and reduced in diameter, its grain structure is refined, resulting in a stronger and more ductile material. This can be important in applications where the wire will be subjected to high tensile forces or bending, as a stronger wire can better withstand these stresses without breaking or deforming.

Overall, the copper wire drawing machine process offers a number of benefits for manufacturers looking to produce high-quality copper wire. By controlling the diameter, surface finish, length, and mechanical properties of the wire, manufacturers can ensure that their products meet the necessary specifications and perform reliably in a variety of applications. Whether used in electrical wiring, telecommunications cables, or other copper products, the wire drawing process can help manufacturers achieve consistent and high-quality results.

Common Issues and Solutions in Copper Wire Drawing Machine Process

Copper wire drawing is a process that involves pulling a copper rod through a series of dies to reduce its diameter and increase its length. This process is essential in the production of copper wire, which is used in a wide range of applications, from electrical wiring to telecommunications. However, like any manufacturing process, copper wire drawing can encounter a number of issues that can affect the quality of the final product. In this article, we will discuss some common issues that can arise during the copper wire drawing process and explore potential solutions to address them.

One of the most common issues in copper wire drawing is die wear. As the copper rod is pulled through the dies, the friction between the rod and the die can cause the die to wear down over time. This can result in an uneven reduction in diameter and an increase in surface roughness of the wire. To address this issue, it is important to regularly inspect the dies for signs of wear and replace them as needed. Using high-quality dies made from materials such as tungsten carbide can also help to reduce wear and prolong the life of the dies.

Another common issue in copper wire drawing is breakage of the wire. This can occur if the wire is pulled too quickly through the dies or if there are defects in the copper rod, such as cracks or impurities. To prevent wire breakage, it is important to control the speed at which the wire is drawn and to ensure that the copper rod is free from defects before the drawing process begins. Additionally, using lubricants and proper cooling techniques can help to reduce friction and heat generation, which can also contribute to wire breakage.

In some cases, copper wire drawing can result in the formation of surface defects on the wire, such as scratches or pits. These defects can be caused by a variety of factors, including improper die alignment, inadequate lubrication, or excessive drawing speed. To address surface defects, it is important to carefully monitor the drawing process and make adjustments as needed. Ensuring that the dies are properly aligned and using high-quality lubricants can help to reduce the occurrence of surface defects and improve the overall quality of the wire.

Finally, another common issue in copper wire drawing is inconsistent wire diameter. This can occur if the dies are not properly aligned or if there are variations in the tension applied to the wire during the drawing process. To address this issue, it is important to regularly calibrate the drawing machine and ensure that the dies are aligned correctly. Additionally, using a closed-loop tension control system can help to maintain consistent tension throughout the drawing process, resulting in more uniform wire diameter.

In conclusion, copper wire drawing is a complex process that can encounter a number of issues that can affect the quality of the final product. By carefully monitoring the drawing process, using high-quality dies and lubricants, and making adjustments as needed, many of these issues can be addressed and resolved. By taking proactive steps to address common issues in copper wire drawing, manufacturers can ensure that they are producing high-quality copper wire that meets the needs of their customers.