Table of Contents

How to Properly Maintain and Troubleshoot a Copper Wire Drawing Machine With Annealer

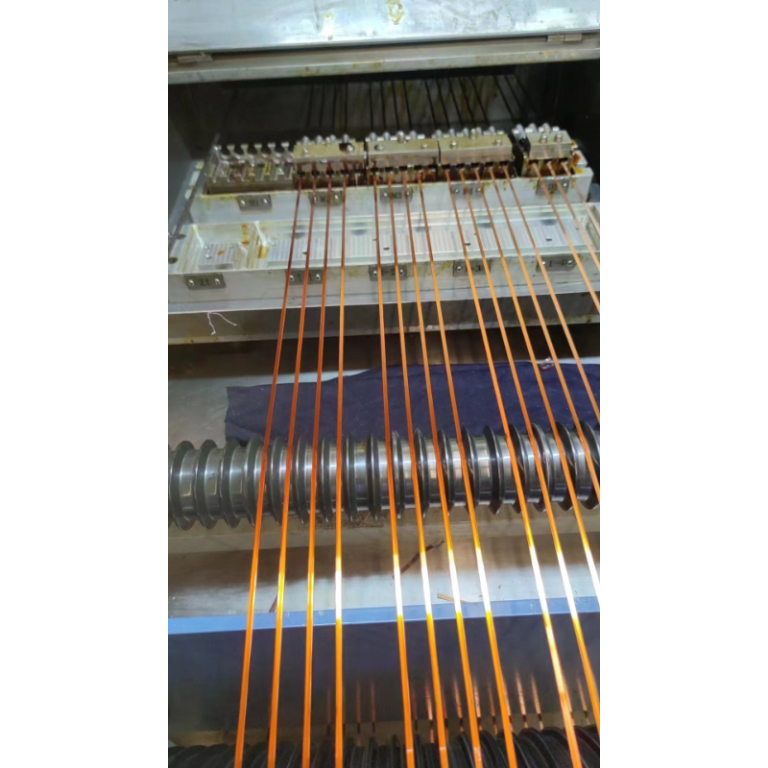

Copper Fine Wire Drawing Machine With Annealer are essential equipment in the wire manufacturing industry. These machines are used to draw copper wire to the desired diameter and anneal it to improve its ductility and conductivity. Proper maintenance and troubleshooting of these machines are crucial to ensure smooth operation and high-quality wire production.

To properly maintain a copper wire drawing machine with annealer, regular cleaning and lubrication are essential. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. Cleaning the machine regularly with a soft brush and compressed air can help prevent these issues. Additionally, lubricating the moving parts with a suitable lubricant will help reduce friction and prolong the machine’s lifespan.

In addition to cleaning and lubrication, it is important to inspect the machine’s components regularly for signs of wear or damage. Check the wire drawing dies, capstans, and annealing furnace for any cracks, chips, or other defects that could affect the wire quality. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure consistent wire production.

Another important aspect of maintaining a copper wire drawing machine with annealer is monitoring the machine’s performance. Keep track of the machine’s speed, tension, and temperature settings to ensure they are within the recommended range for the wire being produced. Any deviations from these settings could indicate a problem with the machine that needs to be addressed promptly.

When troubleshooting a Copper Rod Casting and Making Machine with annealer, it is important to start by identifying the source of the issue. Common problems with these machines include wire breakage, uneven wire diameter, and annealing issues. By carefully observing the machine’s operation and conducting tests, you can pinpoint the cause of the problem and take appropriate action to resolve it.

For example, if the machine is producing wire with uneven diameter, the issue could be due to worn or misaligned wire drawing dies. In this case, replacing the dies or adjusting their alignment can help improve the wire quality. If the wire is breaking frequently, check for any obstructions in the wire path or excessive tension on the wire. Adjusting the tension settings or clearing any obstructions can help prevent wire breakage.

In cases where the annealing process is not producing the desired results, check the temperature settings of the annealing furnace and ensure they are accurate. If the temperature is too high or too low, adjust it accordingly to achieve the desired annealing effect. Additionally, inspect the annealing furnace for any issues such as heating element damage or insulation problems that could affect the annealing process.

In conclusion, proper maintenance and troubleshooting of a copper wire drawing machine with annealer are essential for ensuring high-quality wire production. By following a regular maintenance schedule, inspecting the machine’s components, monitoring its performance, and addressing any issues promptly, you can keep your machine running smoothly and produce high-quality copper wire consistently. Remember to consult the machine’s manual for specific maintenance instructions and seek professional help if needed for complex troubleshooting issues.

Benefits of Using a Copper Wire Drawing Machine With Annealer

Copper Multiwire Drawing Machine with annealers are essential tools in the wire manufacturing industry. These machines are designed to draw copper wire through a series of dies to reduce its diameter and improve its quality. The annealer component of the machine helps to soften the copper wire, making it more malleable and easier to work with. There are several benefits to using a copper wire drawing machine with annealer, including increased productivity, improved wire quality, and reduced production costs.

One of the primary benefits of using a copper wire drawing machine with annealer is increased productivity. These machines are capable of drawing wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. The annealer component of the machine also helps to speed up the drawing process by softening the copper wire, making it easier to draw through the dies. This increased productivity can help manufacturers meet tight production deadlines and fulfill large orders in a timely manner.

In addition to increased productivity, using a copper wire drawing machine with annealer can also improve the quality of the wire being produced. The annealing process helps to remove any internal stresses in the copper wire, resulting in a more uniform and consistent product. This can lead to fewer defects in the wire, such as cracks or breaks, and ultimately result in a higher quality end product. Improved wire quality can also lead to increased customer satisfaction and repeat business, as customers will be more likely to purchase wire that is reliable and durable.

Another benefit of using a copper wire drawing machine with annealer is reduced production costs. By drawing wire at high speeds and improving wire quality, manufacturers can reduce the amount of waste produced during the manufacturing process. This can lead to significant cost savings, as less material is wasted and more wire can be produced from the same amount of raw material. Additionally, the annealing process can help to extend the life of the dies used in the drawing machine, reducing the need for frequent replacements and maintenance. This can further reduce production costs and increase overall profitability for manufacturers.

Overall, using a copper wire drawing machine with annealer can provide numerous benefits for manufacturers in the wire industry. From increased productivity and improved wire quality to reduced production costs, these machines are essential tools for producing high-quality copper wire efficiently and effectively. By investing in a copper wire drawing machine with annealer, manufacturers can streamline their production processes, improve the quality of their products, and ultimately increase their bottom line.