Table of Contents

The Latest Technological Advancements in Copper Wire Drawing Machine from China

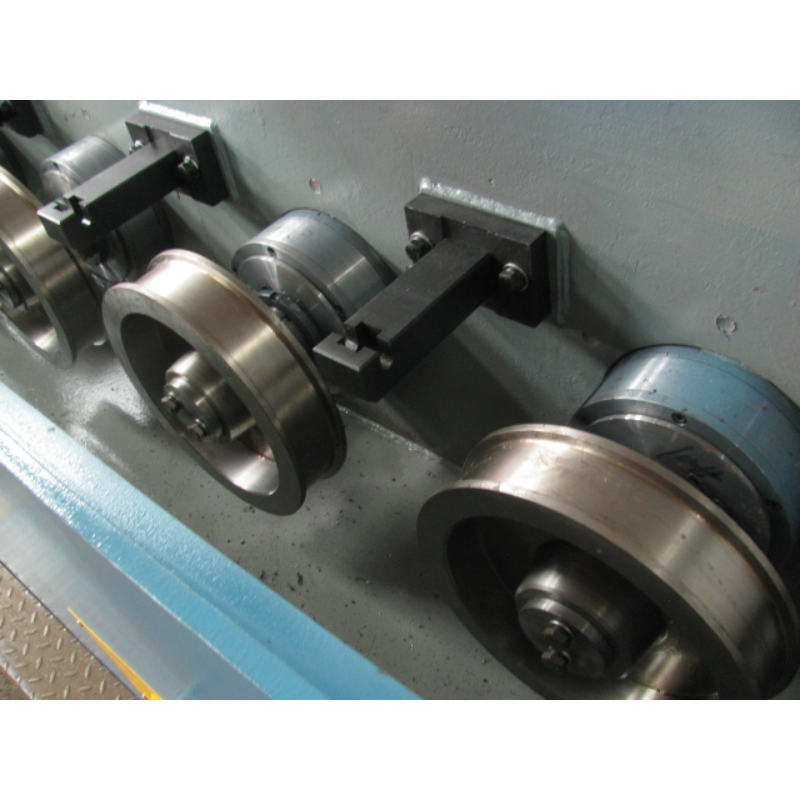

Copper wire drawing machines have become an essential tool in the manufacturing industry, especially in the production of electrical wires and cables. These machines are used to reduce the diameter of copper rods or wires by pulling them through a series of dies, resulting in a smoother and more uniform wire. With the increasing demand for high-quality copper wires, manufacturers are constantly looking for ways to improve the efficiency and performance of these machines.

In recent years, China has emerged as a leading manufacturer of copper wire drawing machines, offering a wide range of advanced technologies and innovative solutions. Chinese factories are known for their high-quality products, competitive prices, and reliable customer service. The latest technological advancements in copper wire drawing machines from China have revolutionized the industry, making it easier and more cost-effective to produce high-quality copper wires.

One of the key advancements in copper wire drawing machines from China is the use of advanced automation and control systems. These systems allow operators to monitor and adjust the machine settings in real-time, ensuring consistent and precise wire drawing. By automating the process, manufacturers can increase productivity, reduce downtime, and improve overall product quality.

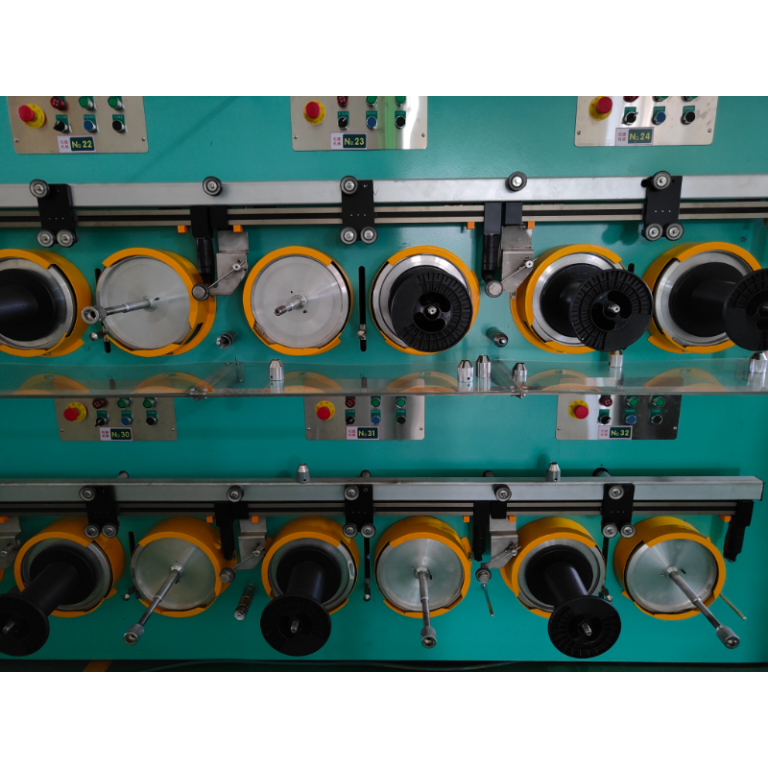

Another important technological advancement in Wet Type Drawing Machines For Copper Wire from China is the use of high-speed motors and drives. These components allow the machines to operate at higher speeds, resulting in faster production rates and increased efficiency. With faster drawing speeds, manufacturers can meet tight production deadlines and fulfill customer orders more quickly.

Furthermore, Chinese manufacturers have also introduced innovative cooling and lubrication systems in their copper wire drawing machines. These systems help to reduce friction and heat during the drawing process, resulting in smoother wire surfaces and improved wire quality. By keeping the dies and wires cool, manufacturers can prevent overheating and extend the lifespan of the machine components.

Additionally, Chinese factories have invested in research and development to improve the design and construction of copper wire drawing machines. By using advanced materials and manufacturing techniques, they have been able to create machines that are more durable, reliable, and energy-efficient. These advancements have helped to reduce maintenance costs and increase the overall lifespan of the machines.

In conclusion, the latest technological advancements in copper wire drawing machines from China have transformed the industry, making it easier and more cost-effective to produce high-quality copper wires. With advanced automation and control systems, high-speed motors and drives, innovative cooling and lubrication systems, and improved machine design, Chinese manufacturers are leading the way in the development of cutting-edge wire drawing technology. As the demand for copper wires continues to grow, these advancements will play a crucial role in meeting the needs of manufacturers around the world. Whether you are looking to increase productivity, improve product quality, or reduce operating costs, copper wire drawing machines from China offer a reliable and efficient solution for your manufacturing needs.

Benefits of Using Copper Wire Drawing Machines in Manufacturing

Copper wire drawing machines have become an essential tool in the manufacturing industry, especially in China where the demand for high-quality copper wire products is on the rise. These machines are designed to pull a copper rod through a series of dies to reduce its diameter and increase its length. This process results in a smoother, stronger, and more uniform copper wire that is ideal for a wide range of applications.

One of the key benefits of using Copper Wire Drawing Machine Process is the ability to produce copper wire with precise dimensions. By controlling the speed at which the copper rod is pulled through the dies, manufacturers can create wire of varying thicknesses to meet specific requirements. This level of precision is crucial in industries such as electronics, telecommunications, and construction, where the quality of the copper wire can directly impact the performance of the final product.

In addition to precise dimensions, copper wire drawing machines also offer improved surface quality. As the copper rod is pulled through the dies, any imperfections or impurities on the surface are smoothed out, resulting in a clean and uniform finish. This is particularly important in applications where the copper wire will be exposed to harsh environments or high temperatures, as a smooth surface can help prevent corrosion and ensure optimal performance.

Furthermore, copper wire drawing machines are highly efficient, allowing manufacturers to produce large quantities of copper wire in a relatively short amount of time. This efficiency not only helps to reduce production costs but also ensures a consistent supply of high-quality copper wire for customers. In a competitive market like China, where demand for copper wire products is constantly growing, this level of efficiency is essential for staying ahead of the competition.

Another advantage of using copper wire drawing machines is the ability to customize the properties of the copper wire to meet specific requirements. By adjusting the speed, temperature, and pressure during the drawing process, manufacturers can create copper wire with different levels of conductivity, strength, and flexibility. This flexibility is particularly valuable in industries such as automotive, aerospace, and renewable energy, where copper wire is used in a wide range of applications with varying performance demands.

Overall, copper wire drawing machines offer a wide range of benefits for manufacturers in China and beyond. From precise dimensions and improved surface quality to increased efficiency and customization options, these machines play a crucial role in producing high-quality copper wire products for a variety of industries. As the demand for copper wire continues to grow, investing in copper wire drawing machines can help manufacturers stay competitive and meet the evolving needs of their customers.

How to Choose the Right Copper Wire Drawing Machine for Your Factory

Copper wire drawing machines are essential equipment for factories that produce copper wire products. These machines are used to reduce the diameter of copper wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. Choosing the right Copper Rod Casting and Making Machine for your factory is crucial to ensure efficient production and high-quality products.

When looking for a copper wire drawing machine, one of the first things to consider is the size and capacity of the machine. The size of the machine should be able to accommodate the diameter of the copper wire you will be working with. Additionally, the machine should have the capacity to handle the volume of wire that your factory produces. It is important to choose a machine that can meet your production needs without being overworked, as this can lead to decreased efficiency and increased maintenance costs.

Another important factor to consider when choosing a copper wire drawing machine is the number of dies that the machine has. The number of dies determines how many times the wire will be pulled through to achieve the desired diameter. Machines with more dies are able to achieve a more precise reduction in diameter, resulting in a higher quality finished product. However, machines with more dies are typically more expensive and may require more maintenance.

In addition to size and capacity, it is important to consider the speed and power of the copper wire drawing machine. The speed of the machine will determine how quickly the wire can be drawn through the dies, while the power of the machine will determine how efficiently it can handle the drawing process. It is important to choose a machine that has the right balance of speed and power for your production needs.

When choosing a copper wire drawing machine, it is also important to consider the reputation of the manufacturer. Look for a manufacturer with a history of producing high-quality machines that are reliable and durable. Reading reviews and testimonials from other customers can help you determine the reputation of a manufacturer and the quality of their products.

Finally, consider the cost of the copper wire drawing machine. While it is important to choose a machine that meets your production needs, it is also important to consider your budget. Compare prices from different manufacturers and consider the long-term costs of maintenance and repairs. It may be worth investing in a higher quality machine that will last longer and require less maintenance in the long run.

In conclusion, choosing the right copper wire drawing machine for your factory is essential to ensure efficient production and high-quality products. Consider factors such as size, capacity, number of dies, speed, power, manufacturer reputation, and cost when making your decision. By carefully evaluating these factors, you can choose a machine that meets your production needs and helps your factory produce top-quality copper wire products.