Table of Contents

Tips for Maintaining and Cleaning Single Block Wire Drawing Machine for Aluminum Wire

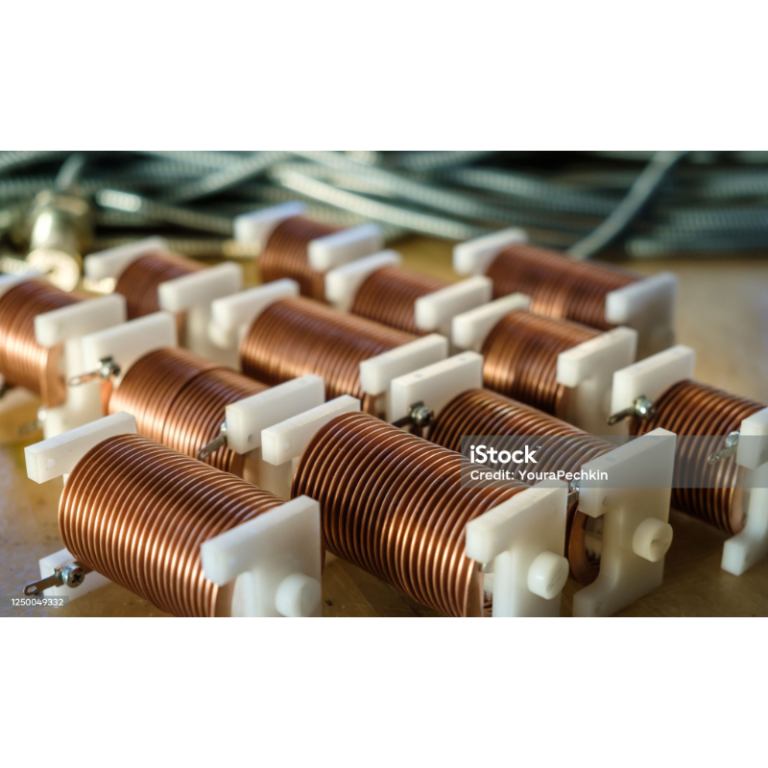

Single block wire drawing machines are essential tools in the manufacturing industry for producing high-quality aluminum wire. These machines are designed to pull aluminum wire through a series of dies to reduce its diameter and improve its mechanical properties. To ensure the longevity and efficiency of a single block wire drawing machine, proper maintenance and cleaning are crucial. In this article, we will discuss some tips for maintaining and cleaning a Rod Breakdown Machine for Aluminum Wire.

Regular maintenance is key to keeping a single block wire drawing machine in optimal working condition. One of the most important maintenance tasks is lubrication. Proper lubrication of the machine’s moving parts helps reduce friction and wear, extending the machine’s lifespan. It is recommended to use a high-quality lubricant that is suitable for the specific components of the machine. Regularly inspecting the machine for signs of wear and tear, such as worn-out dies or damaged rollers, is also essential. Any damaged parts should be replaced promptly to prevent further damage to the machine.

Cleaning the single block wire drawing machine is another crucial aspect of maintenance. Over time, dirt, dust, and metal shavings can accumulate on the machine’s surfaces, affecting its performance. Regularly cleaning the machine with a soft brush or cloth can help prevent buildup and ensure smooth operation. It is important to pay special attention to the dies and rollers, as any debris stuck in these components can cause damage to the wire being drawn. Using a mild solvent or cleaning solution can help remove stubborn dirt and grease from the machine.

In addition to regular maintenance and cleaning, it is important to follow proper operating procedures when using a single block wire drawing machine. Overloading the machine or running it at excessive speeds can cause unnecessary stress on the components, leading to premature wear and potential breakdowns. It is important to follow the manufacturer’s guidelines for operating the machine and to avoid any practices that could damage the machine or compromise the quality of the wire being produced.

Proper storage of the single block wire drawing machine is also important for maintaining its longevity. When not in use, the machine should be stored in a clean, dry environment to prevent rust and corrosion. It is recommended to cover the machine with a protective tarp or sheet to shield it from dust and moisture. Additionally, storing the machine in a secure location away from heavy machinery or other potential hazards can help prevent accidental damage.

In conclusion, maintaining and cleaning a Aluminum Alloy Wire Drawing Machine is essential for ensuring its longevity and efficiency. By following these tips and guidelines, manufacturers can keep their machines in optimal working condition and produce high-quality aluminum wire consistently. Regular maintenance, proper cleaning, following operating procedures, and storing the machine correctly are all key aspects of keeping a single block wire drawing machine in top shape. By investing time and effort into maintaining and cleaning the machine, manufacturers can maximize its lifespan and productivity, ultimately leading to better results and cost savings in the long run.

Comparison of Different Single Block Wire Drawing Machines for Aluminum Wire

Single block wire drawing machines are essential equipment in the wire manufacturing industry, particularly for aluminum wire production. These machines are designed to reduce the diameter of wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. In this article, we will compare different single block wire drawing machines for aluminum wire, focusing on their features, capabilities, and performance.

One of the key factors to consider when choosing a single block wire drawing machine for aluminum wire is the material of the drawing dies. Tungsten carbide is a popular choice for drawing dies due to its hardness and wear resistance, which ensures a longer lifespan and consistent performance. Machines equipped with tungsten carbide drawing dies are capable of drawing aluminum wire to smaller diameters with minimal wear and tear on the dies.

Another important feature to look for in a single block wire drawing machine is the number of drafts or passes that the wire can undergo. Machines with multiple drafts allow for more precise control over the reduction in wire diameter, resulting in a higher quality finished product. Additionally, machines with variable speed control can adjust the drawing speed to accommodate different wire sizes and materials, further enhancing the versatility and efficiency of the machine.

In terms of performance, the motor power and speed of the single block wire drawing machine play a crucial role in determining its productivity and output quality. Machines with higher motor power can handle larger wire sizes and draw them to smaller diameters more efficiently. Similarly, machines with adjustable speed settings can optimize the drawing process for different wire types, ensuring consistent results and minimizing downtime.

When comparing different Aluminum Wire Drawing Machine, it is also important to consider the overall design and construction of the machine. Machines with a sturdy frame and reliable components are more likely to withstand the rigors of continuous operation and deliver consistent performance over time. Additionally, machines with user-friendly controls and safety features make it easier for operators to set up and operate the machine, reducing the risk of accidents and downtime.

In conclusion, single block wire drawing machines are essential equipment for aluminum wire production, offering precision, efficiency, and versatility in the wire manufacturing process. When choosing a single block wire drawing machine for aluminum wire, it is important to consider factors such as the material of the drawing dies, number of drafts, motor power, speed, and overall design. By selecting a machine that meets your specific requirements and quality standards, you can ensure a smooth and efficient wire drawing process that produces high-quality aluminum wire for various applications.

Benefits of Using Single Block Wire Drawing Machine for Aluminum Wire

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wires, including aluminum wire. One of the key machines used in this process is the wire drawing machine, which helps to achieve the desired diameter and surface finish of the wire. In recent years, the single block wire drawing machine has gained popularity for its efficiency and effectiveness in drawing aluminum wire.

One of the main benefits of using a single block wire drawing machine for aluminum wire is its compact design. Unlike traditional multi-block wire drawing machines, which consist of multiple blocks through which the wire passes, a single block machine has only one block. This design not only saves space but also simplifies the wire drawing process, making it easier to operate and maintain.

Another advantage of using a single block wire drawing machine for aluminum wire is its versatility. These machines are capable of drawing wires of various diameters, making them suitable for a wide range of applications. Whether you need to produce thin wires for electrical applications or thicker wires for structural purposes, a single block machine can handle the job with ease.

In addition to its compact design and versatility, a single block wire drawing machine offers improved efficiency compared to traditional multi-block machines. By reducing the number of blocks through which the wire passes, these machines minimize friction and wear on the wire, resulting in a smoother drawing process and higher quality finished product. This not only saves time and energy but also reduces the need for frequent maintenance and replacement of parts.

Furthermore, single block wire drawing machines are known for their precision and consistency in producing uniform wire diameters. The single block design allows for better control over the drawing process, ensuring that the wire is drawn to the exact specifications required. This level of precision is essential in industries where quality and accuracy are paramount, such as aerospace and automotive manufacturing.

In conclusion, the single block wire drawing machine offers several benefits for drawing aluminum wire. Its compact design, versatility, efficiency, precision, and consistency make it an ideal choice for manufacturers looking to produce high-quality wires with minimal downtime and maintenance. Whether you are producing wires for electrical, structural, or other applications, a single block machine can help you achieve the desired results with ease. Consider investing in a single block wire drawing machine for your aluminum wire drawing needs and experience the difference it can make in your production process.