Table of Contents

Tips for Choosing the Right Fine Wire Drawing Machine For Aluminum Wire

When it comes to choosing the right fine wire drawing machine for aluminum wire, there are several factors to consider in order to ensure optimal performance and efficiency. Fine wire drawing machines are essential for the production of high-quality aluminum wire used in a variety of industries, including electronics, construction, and automotive. By selecting the right machine for your specific needs, you can improve the quality of your products and increase productivity.

One of the most important factors to consider when choosing a fine wire drawing machine for aluminum wire is the size and type of wire you will be working with. Different machines are designed to handle different wire sizes and types, so it is crucial to select a machine that is compatible with the specific requirements of your production process. Additionally, consider the speed and capacity of the machine, as these factors will impact the overall efficiency of your operation.

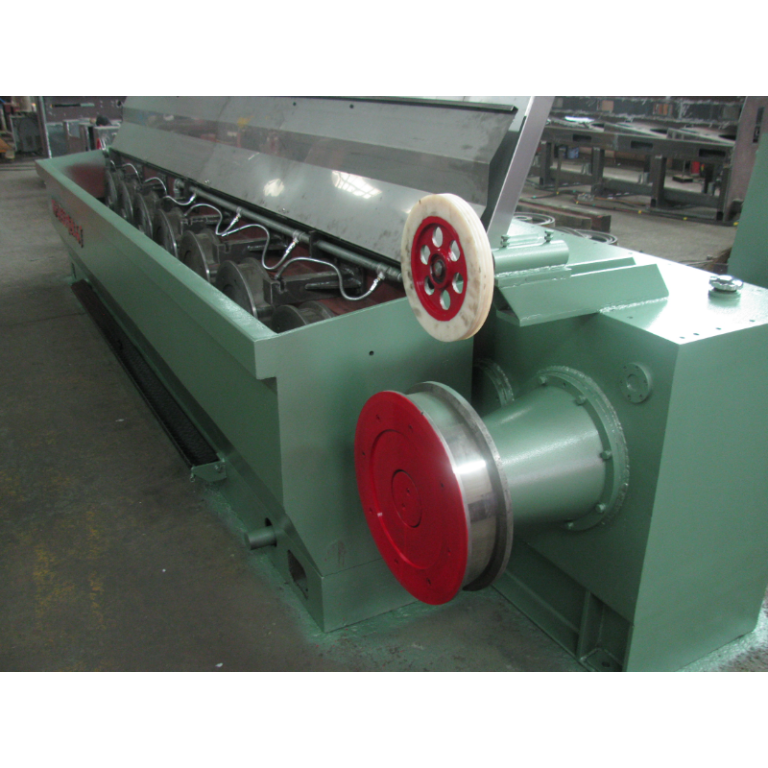

Another key consideration when choosing a Water-Tank Wire Drawing Machine For Aluminum Wire is the quality of the materials used in its construction. High-quality materials will ensure the durability and longevity of the machine, reducing the need for frequent maintenance and repairs. Look for machines made from sturdy materials such as stainless steel or aluminum, as these materials are known for their strength and resistance to corrosion.

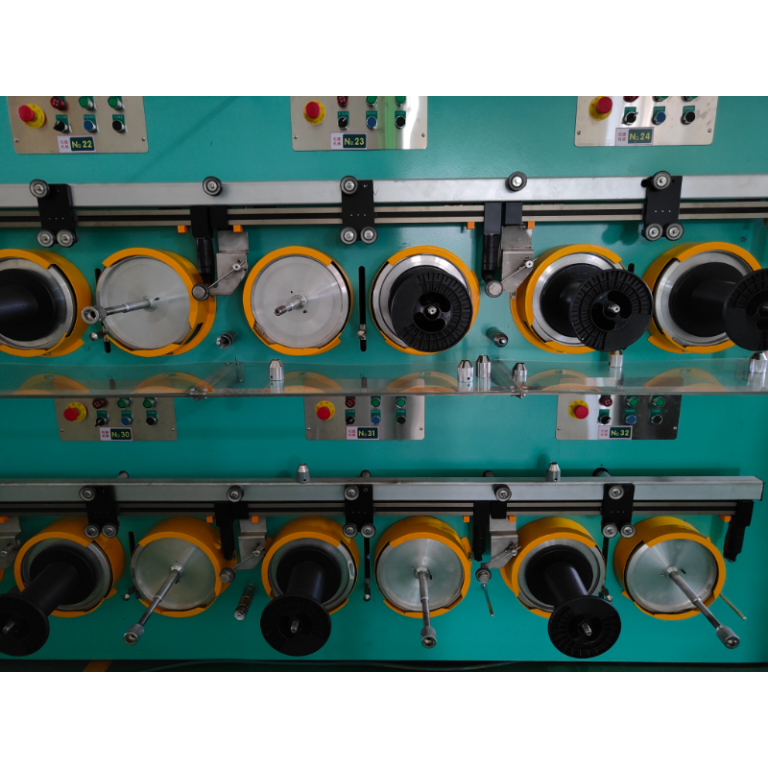

In addition to the materials used in the construction of the machine, it is important to consider the technology and features available. Modern fine wire drawing machines are equipped with advanced technology that can improve the precision and efficiency of the drawing process. Look for machines with features such as digital controls, automatic lubrication systems, and adjustable speed settings to ensure optimal performance.

When selecting a fine wire drawing machine for aluminum wire, it is also important to consider the reputation and reliability of the manufacturer. Choose a reputable manufacturer with a track record of producing high-quality machines that meet industry standards. Reading customer reviews and testimonials can help you gauge the reliability and performance of a particular machine before making a purchase.

Finally, consider the cost of the machine and weigh it against the benefits it will provide to your production process. While it may be tempting to opt for a cheaper machine, investing in a high-quality fine wire drawing machine will ultimately save you time and money in the long run. Consider the return on investment and choose a machine that offers the best value for your specific needs.

In conclusion, choosing the right fine wire drawing machine for aluminum wire is essential for ensuring the quality and efficiency of your production process. Consider factors such as wire size, materials, technology, manufacturer reputation, and cost when making your decision. By selecting a high-quality machine that meets your specific requirements, you can improve the performance of your operation and produce high-quality aluminum wire for a variety of applications.

Benefits of Using Fine Wire Drawing Machine for Aluminum Wire

Fine wire drawing machines are essential tools in the manufacturing industry, especially when it comes to producing aluminum wire. These machines are designed to pull a wire through a series of dies to reduce its diameter and improve its quality. The process involves drawing the wire through a die or series of dies to reduce its diameter and improve its surface finish. This results in a wire that is stronger, more flexible, and has better electrical conductivity.

One of the main benefits of using a fine wire drawing machine for Aluminum Wire Drawing Machine is the ability to produce wire with precise dimensions. The machine can control the diameter of the wire to within very tight tolerances, ensuring that the final product meets the required specifications. This is crucial in industries such as electronics, where the wire must meet strict standards for conductivity and flexibility.

Another advantage of using a fine wire drawing machine is the ability to improve the surface finish of the wire. The drawing process helps to remove any imperfections or impurities from the surface of the wire, resulting in a smoother and more uniform finish. This is important in applications where the wire will be exposed to harsh environments or where a high level of conductivity is required.

In addition to improving the quality of the wire, using a fine wire drawing machine can also increase the production efficiency. These machines are capable of drawing wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help to reduce production costs and improve overall productivity.

Furthermore, fine wire drawing machines are versatile tools that can be used to produce wire in a variety of sizes and shapes. This flexibility allows manufacturers to create custom wire products to meet the specific needs of their customers. Whether it’s a thin wire for electronics or a thicker wire for construction, a fine wire drawing machine can handle a wide range of wire sizes and materials.

In conclusion, the benefits of using a fine wire drawing machine for aluminum wire are numerous. From improving the quality and surface finish of the wire to increasing production efficiency and versatility, these machines play a crucial role in the manufacturing industry. By investing in a fine wire drawing machine, manufacturers can ensure that they are producing high-quality wire products that meet the demands of their customers.

Maintenance and Care Tips for Fine Wire Drawing Machine for Aluminum Wire

Fine wire drawing machines are essential equipment in the manufacturing industry, particularly for producing aluminum wire. These machines are designed to pull the wire through a series of dies to reduce its diameter and improve its quality. To ensure the longevity and efficiency of a fine wire drawing machine for aluminum wire, proper maintenance and care are crucial.

One of the most important maintenance tasks for a fine wire drawing machine is regular cleaning. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential damage. It is recommended to clean the machine after each use to prevent build-up and ensure smooth operation. Use a soft brush or cloth to remove any particles from the machine’s surface, dies, and rollers.

In addition to cleaning, lubrication is another key aspect of maintaining a fine wire drawing machine. Proper lubrication helps reduce friction between moving parts, prolonging the machine’s lifespan and preventing wear and tear. It is important to use the correct type of lubricant recommended by the manufacturer and apply it to the designated areas regularly. Over-lubrication should be avoided as it can attract more dirt and debris, leading to potential issues.

Regular inspection of the machine’s components is also essential for detecting any signs of wear or damage. Check the dies, rollers, and other parts for any cracks, dents, or abnormalities that may affect the wire drawing process. Replace any worn-out or damaged parts immediately to prevent further damage to the machine and ensure consistent performance.

Proper tension adjustment is another crucial maintenance task for a fine wire drawing machine. The tension of the wire plays a significant role in the drawing process, and improper tension can result in uneven wire diameter and quality issues. Regularly check and adjust the tension settings according to the wire size and material being drawn to achieve optimal results.

In addition to regular maintenance tasks, it is important to follow the manufacturer’s guidelines for operating the fine wire drawing machine. Avoid overloading the machine beyond its capacity, as this can lead to overheating and premature wear. Follow proper start-up and shutdown procedures to prevent damage to the machine and ensure safe operation.

Proper storage of the fine wire drawing machine is also important to protect it from environmental factors that can cause corrosion or damage. Store the machine in a clean, dry area away from moisture and direct sunlight. Cover the machine when not in use to prevent dust and debris from accumulating on its surface.

In conclusion, proper maintenance and care are essential for ensuring the longevity and efficiency of a fine wire drawing machine for aluminum wire. Regular cleaning, lubrication, inspection, tension adjustment, and following manufacturer guidelines are key aspects of maintaining the machine. By taking these steps, manufacturers can prolong the lifespan of their equipment and achieve consistent, high-quality results in the wire drawing process.