Table of Contents

Comparison of Different Rod Breakdown Machine for Copper Wire Manufacturing

Rod breakdown machines are essential equipment in the manufacturing process of copper wire. These machines are used to reduce the diameter of copper rods to the desired size for further processing. There are several models of rod breakdown machines available in the market, each with its own unique features and capabilities. In this article, we will compare different rod breakdown machine models for Copper Multiwire Drawing Machine manufacturing to help you make an informed decision when choosing the right machine for your production needs.

One of the key factors to consider when comparing rod breakdown machine models is the maximum rod diameter that the machine can handle. Some machines are designed to handle smaller diameter rods, while others are capable of processing larger diameter rods. The maximum rod diameter that a machine can handle will determine the range of wire sizes that can be produced. It is important to choose a machine that can accommodate the rod diameter that is suitable for your production requirements.

Another important factor to consider is the speed at which the machine can operate. The production efficiency of a rod breakdown machine is directly related to its processing speed. Machines that can operate at higher speeds will be able to produce more wire in a shorter amount of time, increasing overall productivity. However, it is important to balance speed with quality to ensure that the wire produced meets the required specifications.

The quality of the wire produced by a rod breakdown machine is also a critical factor to consider. The machine should be able to produce wire with consistent diameter and surface finish to meet the quality standards of the industry. Some machines are equipped with advanced features such as automatic tension control and monitoring systems to ensure that the wire produced is of high quality. It is important to choose a machine that can deliver consistent and reliable performance to meet the demands of your customers.

In addition to the technical specifications of the machine, it is also important to consider the overall cost of ownership. This includes not only the initial purchase price of the machine but also maintenance and operating costs. Some machines may require more frequent maintenance or have higher energy consumption, which can increase the overall cost of ownership. It is important to evaluate the total cost of ownership over the lifespan of the machine to determine the most cost-effective option for your production needs.

When comparing different rod breakdown machine models, it is important to consider the reputation and reliability of the manufacturer. Choose a reputable manufacturer with a proven track record of delivering high-quality machines and excellent customer support. A reliable manufacturer will provide technical assistance, spare parts, and service support to ensure that your machine operates efficiently and effectively.

In conclusion, choosing the right rod breakdown machine for copper wire manufacturing is a critical decision that can impact the productivity and quality of your production process. Consider factors such as maximum rod diameter, processing speed, wire quality, cost of ownership, and manufacturer reputation when comparing different machine models. By making an informed decision, you can ensure that your production process runs smoothly and efficiently, meeting the demands of your customers and industry standards.

Benefits of Using Rod Breakdown Machine for Copper Wire Production

Copper wire is a crucial component in various industries, including telecommunications, electronics, and power distribution. To meet the growing demand for copper wire, manufacturers rely on efficient machinery to produce high-quality products. One such machine that plays a vital role in the production process is the rod breakdown machine.

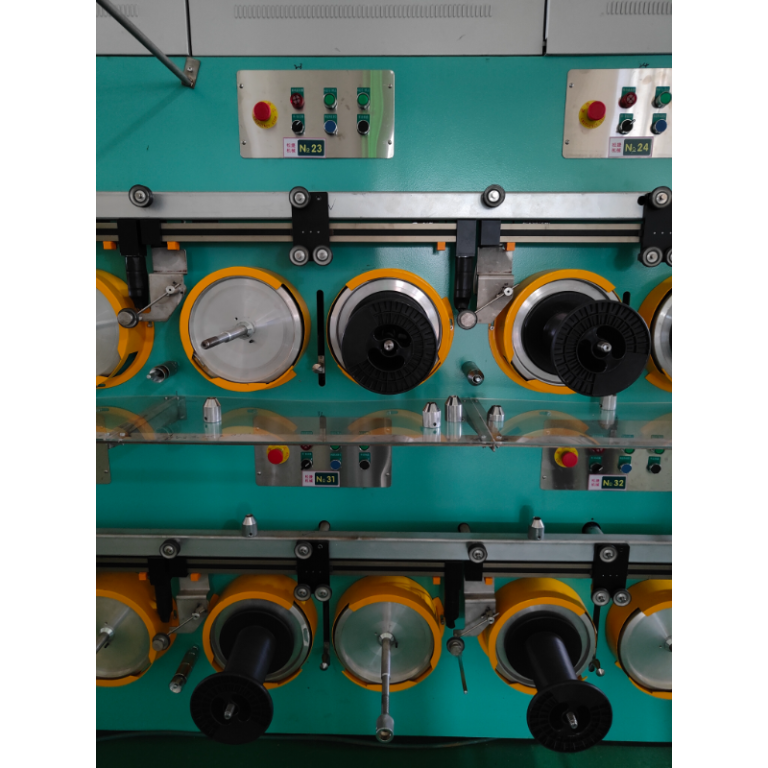

The rod breakdown machine is specifically designed to reduce the diameter of copper rods to the desired size for wire drawing. This machine is essential in the initial stages of wire production, as it helps in preparing the raw material for further processing. By using a rod breakdown machine, manufacturers can achieve consistent wire diameter and improve the overall quality of the final product.

One of the key benefits of using a rod breakdown machine is its ability to increase productivity. This machine is capable of processing large quantities of copper rods in a short amount of time, allowing manufacturers to meet tight production deadlines. By automating the rod reduction process, manufacturers can streamline their operations and improve efficiency.

In addition to improving productivity, the Copper Wire Drawing Machine for Rod Breakdown Machine also helps in reducing material waste. By precisely reducing the diameter of copper rods, manufacturers can minimize the amount of scrap generated during the wire drawing process. This not only helps in reducing production costs but also contributes to a more sustainable manufacturing process.

Another advantage of using a rod breakdown machine is its ability to enhance the quality of the copper wire produced. By ensuring uniform diameter and smooth surface finish, this machine helps in producing high-quality wire that meets industry standards. This is essential for industries that require reliable and durable copper wire for their applications.

Furthermore, the rod breakdown machine offers flexibility in wire production. Manufacturers can easily adjust the machine settings to produce different wire diameters according to their specific requirements. This flexibility allows manufacturers to cater to a wide range of customer needs and adapt to changing market demands.

Moreover, the rod breakdown machine is designed for easy maintenance and operation. With minimal downtime and reduced maintenance costs, manufacturers can maximize the machine’s uptime and ensure continuous production. This reliability is crucial for meeting customer deadlines and maintaining a competitive edge in the market.

Overall, the rod breakdown machine is a valuable asset for copper wire manufacturers looking to improve their production processes. By increasing productivity, reducing material waste, enhancing quality, and offering flexibility, this machine plays a crucial role in ensuring efficient and cost-effective wire production. With its ease of maintenance and operation, manufacturers can rely on this machine to meet their production goals and deliver high-quality copper wire to their customers.

Maintenance Tips for Rod Breakdown Machine to Ensure Longevity

Rod breakdown machines are essential equipment in the wire and cable industry, used to reduce the diameter of copper rods to produce various sizes of copper wire. These machines are complex pieces of machinery that require regular maintenance to ensure optimal performance and longevity. In this article, we will discuss some maintenance tips for rod breakdown machines to help you keep your equipment in top condition.

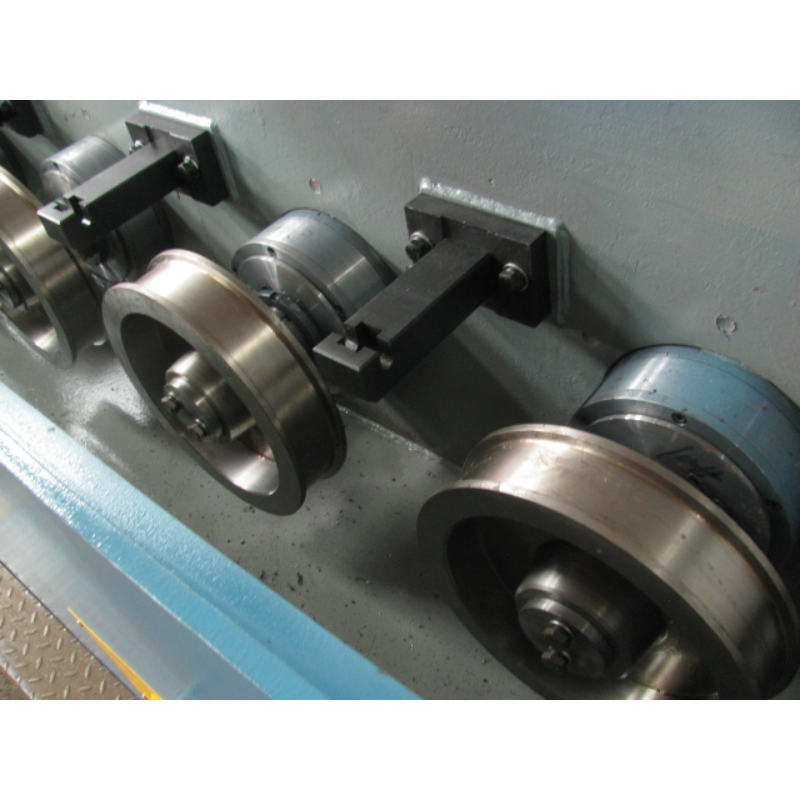

One of the most important maintenance tasks for rod breakdown machines is regular cleaning. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. It is essential to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts of the machine with a suitable lubricant will help reduce friction and wear, prolonging the machine’s lifespan.

Another crucial aspect of copper wire drawing machine maintenance is inspecting the machine for any signs of wear or damage. Regularly check the machine’s components, such as the dies, rollers, and bearings, for any signs of wear or corrosion. If any parts show signs of damage, they should be replaced immediately to prevent further damage to the machine. Additionally, checking the machine’s alignment and tension regularly will help ensure that the machine operates smoothly and efficiently.

In addition to regular cleaning and inspection, it is essential to follow the manufacturer’s recommended maintenance schedule for your rod breakdown machine. This schedule will outline specific maintenance tasks that need to be performed at regular intervals, such as replacing worn parts, adjusting tension, and calibrating the machine. By following the manufacturer’s recommendations, you can ensure that your machine operates at its best and avoid costly repairs or downtime.

Proper training for machine operators is also crucial for maintaining rod breakdown machines. Operators should be trained on how to operate the machine safely and efficiently, as well as how to perform basic maintenance tasks. By ensuring that operators are properly trained, you can prevent accidents and damage to the machine caused by operator error.

In conclusion, regular maintenance is essential for ensuring the longevity and optimal performance of rod breakdown machines. By following these maintenance tips, you can keep your machine in top condition and avoid costly repairs or downtime. Remember to clean the machine regularly, inspect for wear or damage, follow the manufacturer’s recommended maintenance schedule, and provide proper training for machine operators. By taking care of your rod breakdown machine, you can ensure that it continues to produce high-quality copper wire for years to come.