Table of Contents

Benefits of Using Flat Wire Enameling Machine

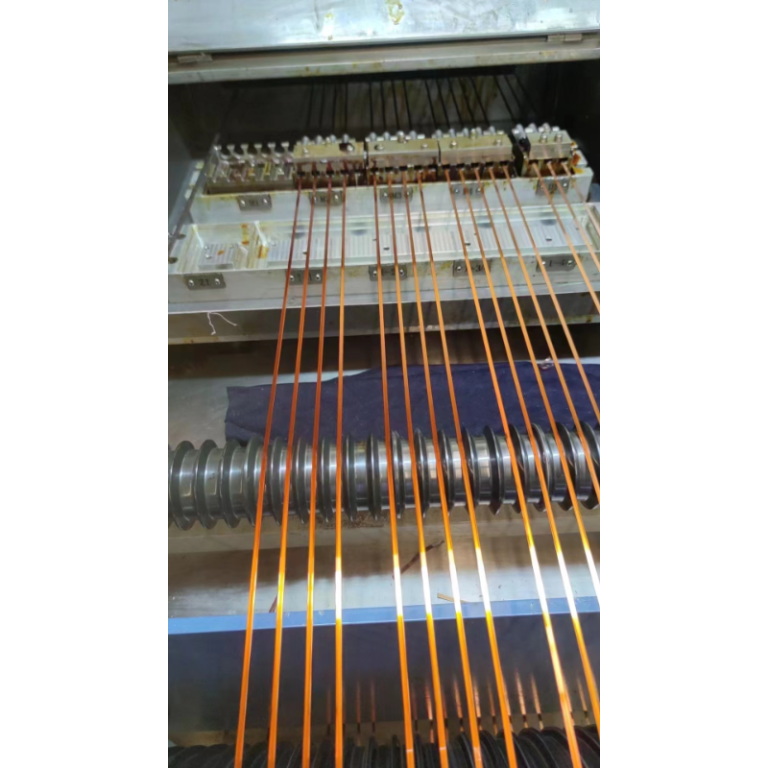

Flat wire enameling machines are a crucial piece of equipment in the manufacturing industry, particularly for companies that produce electrical components. These machines are designed to apply a thin layer of enamel coating onto flat wires, which serves to insulate the wire and protect it from corrosion. The process of enameling flat wires involves passing the wire through a series of heated chambers where the enamel is applied and cured, resulting in a smooth and uniform coating.

One of the key benefits of using a flat wire enameling machine is the efficiency it brings to the production process. These machines are capable of enameling wires at a much faster rate than manual methods, allowing manufacturers to increase their output and meet the demands of their customers. Additionally, the automated nature of these machines reduces the risk of human error, resulting in a higher quality finished product.

Another advantage of using a flat wire enameling machine is the consistency it provides in terms of the thickness and coverage of the enamel coating. Manual enameling methods can often result in uneven coatings, which can lead to issues such as short circuits or premature wire failure. By using a machine to apply the enamel, manufacturers can ensure that each wire is coated uniformly, resulting in a more reliable end product.

In addition to improving the quality and efficiency of the production process, flat wire enameling machines also offer cost savings for manufacturers. While the initial investment in a machine may be significant, the long-term savings in terms of labor costs and reduced scrap rates can quickly offset this expense. By automating the enameling process, manufacturers can also reduce the amount of waste generated during production, further contributing to cost savings and environmental sustainability.

Furthermore, flat wire enameling machines are versatile and can be used to enamel a wide range of wire sizes and materials. This flexibility allows manufacturers to adapt to changing market demands and produce a variety of products without the need for multiple machines. Additionally, some machines are equipped with features such as adjustable speed and temperature settings, allowing manufacturers to customize the enameling process to meet their specific requirements.

Overall, the benefits of using a flat wire enameling machine are clear. From increased efficiency and consistency to cost savings and versatility, these machines offer a range of advantages for manufacturers in the electrical industry. By investing in a flat wire enameling machine, companies can improve the quality of their products, increase their production capacity, and stay competitive in a rapidly evolving market.

How to Choose the Right Flat Wire Enameling Machine for Your Needs

Flat wire enameling machines are essential tools for manufacturers who work with flat wires in various industries such as electronics, automotive, and telecommunications. These machines are used to apply a thin layer of enamel coating to flat wires, which helps to insulate them and protect them from corrosion. Choosing the right flat wire enameling machine for your needs is crucial to ensure the quality and efficiency of your production process.

When selecting a flat wire enameling machine, there are several factors to consider. One of the most important factors is the size and type of flat wire that you will be working with. Flat wires come in different sizes and materials, so it is essential to choose a machine that is compatible with the specific type of flat wire that you will be using. Additionally, consider the production volume that you will be handling, as this will determine the capacity and speed of the machine that you need.

Another important factor to consider when choosing a flat wire enameling machine is the type of enamel coating that you will be applying. There are different types of enamel coatings available, each with its own properties and application requirements. Some machines are designed to work with specific types of enamel coatings, so it is essential to choose a machine that is compatible with the type of enamel that you will be using.

In addition to the size, type of flat wire, and enamel coating, it is also important to consider the features and capabilities of the flat wire enameling machine. Look for machines that offer adjustable speed and temperature settings, as well as automatic feeding and cutting mechanisms. These features can help to improve the efficiency and quality of your production process.

When choosing a flat wire enameling machine, it is also important to consider the reputation and reliability of the manufacturer. Look for manufacturers that have a proven track record of producing high-quality machines that are durable and reliable. Reading customer reviews and testimonials can also help you gauge the quality of the machine and the level of customer satisfaction.

Finally, consider your budget when choosing a flat wire enameling machine. Prices for these machines can vary depending on the size, features, and capabilities of the machine. It is essential to set a budget and stick to it while also considering the long-term benefits and return on investment that the machine will provide.

In conclusion, choosing the right flat wire enameling machine for your needs is crucial to ensure the quality and efficiency of your production process. Consider factors such as the size and type of flat wire, enamel coating, features and capabilities, manufacturer reputation, and budget when making your decision. By taking the time to research and evaluate your options, you can find a machine that meets your specific requirements and helps you achieve your production goals.

Maintenance Tips for Flat Wire Enameling Machine

Flat wire enameling machines are essential tools in the manufacturing industry for coating flat wires with enamel to protect them from corrosion and improve their electrical insulation properties. To ensure the smooth operation and longevity of these machines, regular maintenance is crucial. In this article, we will discuss some maintenance tips for flat wire enameling machines to help you keep them in top condition.

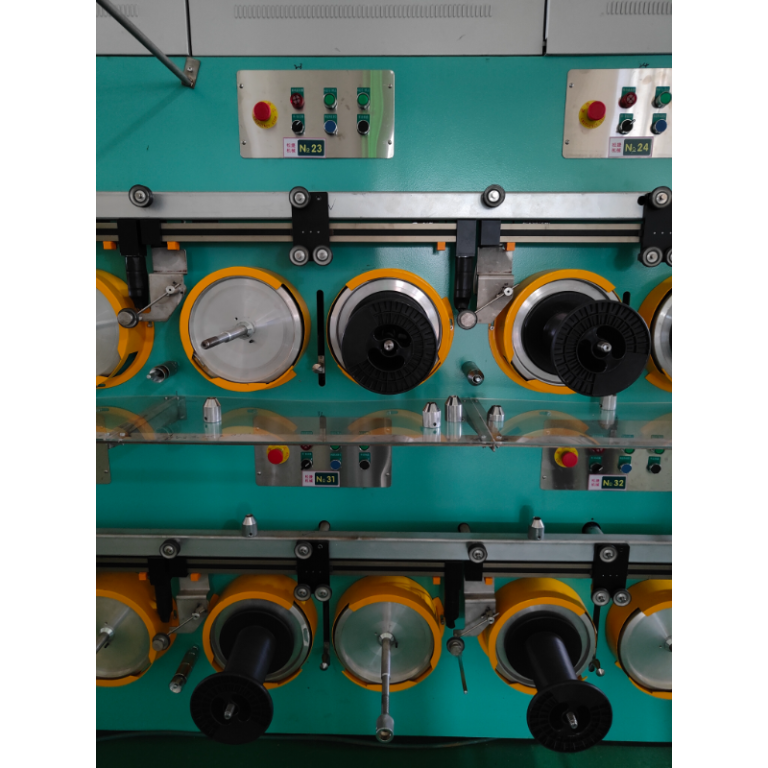

One of the most important maintenance tasks for flat wire enameling machines is cleaning. Over time, dust, dirt, and enamel residue can build up on the machine’s components, leading to decreased efficiency and potential malfunctions. Regularly cleaning the machine with a soft brush and a mild detergent can help prevent these issues. Pay special attention to the wire guides, pulleys, and heating elements, as these are the areas most prone to buildup.

In addition to cleaning, it is essential to inspect the machine’s components regularly for signs of wear and tear. Check the wire guides for any signs of damage or misalignment, as this can affect the quality of the enamel coating. Inspect the heating elements for any cracks or corrosion, as these can lead to uneven heating and poor enamel adhesion. Replace any worn or damaged components promptly to prevent further damage to the machine.

Another crucial maintenance task for flat wire enameling machines is lubrication. Proper lubrication of the machine’s moving parts, such as the pulleys and rollers, can help reduce friction and wear, prolonging the machine’s lifespan. Use a high-quality lubricant recommended by the manufacturer and follow the lubrication schedule outlined in the machine’s manual. Be sure to clean the parts thoroughly before applying the lubricant to prevent contamination.

Regular calibration of the machine is also essential to ensure consistent enamel coating quality. Check the machine’s temperature settings, wire tension, and speed controls regularly to ensure they are within the specified range. Make any necessary adjustments to maintain optimal performance. It is also a good idea to keep a record of the machine’s calibration history to track any changes over time and identify potential issues before they become major problems.

Lastly, it is crucial to follow proper safety procedures when performing maintenance on flat wire enameling machines. Always disconnect the machine from power sources before cleaning or inspecting it to prevent accidents. Wear appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself from potential hazards. If you are unsure about how to perform a maintenance task, consult the machine’s manual or contact the manufacturer for guidance.

In conclusion, regular maintenance is essential for keeping flat wire enameling machines in top condition and ensuring their longevity. By following these maintenance tips, you can prevent malfunctions, prolong the machine’s lifespan, and maintain consistent enamel coating quality. Remember to clean the machine regularly, inspect its components for wear and tear, lubricate moving parts, calibrate the machine as needed, and follow proper safety procedures. With proper maintenance, your flat wire enameling machine will continue to provide reliable performance for years to come.