Table of Contents

Benefits of Using Galvanized Wire in Various Applications

Copper Wire Drawing Machine is a type of wire that has been coated with a layer of zinc to protect it from corrosion and rust. This process involves immersing the wire in a bath of molten zinc, which forms a protective barrier around the wire. Galvanized wire is commonly used in a variety of applications due to its durability and resistance to the elements.

One of the main benefits of using galvanized wire is its resistance to corrosion. The zinc coating on galvanized wire acts as a barrier between the wire and the surrounding environment, preventing rust and corrosion from forming. This makes galvanized wire an ideal choice for outdoor applications where the wire will be exposed to moisture and other corrosive elements.

Another benefit of using galvanized wire is its strength and durability. The zinc coating adds an extra layer of protection to the wire, making it more resistant to bending and breaking. This makes galvanized wire a popular choice for applications that require a strong and reliable wire, such as fencing, construction, and automotive industries.

Galvanized wire is also known for its versatility and ease of use. It can be easily bent, twisted, and cut to fit a variety of applications, making it a versatile option for a wide range of projects. Additionally, galvanized wire is easy to work with and can be welded, soldered, or brazed without any special equipment.In addition to its durability and versatility, galvanized wire is also cost-effective. The zinc coating on galvanized wire helps to extend the life of the wire, reducing the need for frequent replacements. This can result in cost savings over time, making galvanized wire a cost-effective option for many applications.

One common application of galvanized wire is in the construction industry. Galvanized wire is often used to reinforce concrete structures, such as bridges, buildings, and highways. The corrosion-resistant properties of galvanized wire make it an ideal choice for these applications, as it helps to extend the life of the structure and reduce maintenance costs.

Galvanized wire is also commonly used in the agricultural industry. It is often used to build fences, cages, and other structures to contain livestock and protect crops. The durability and strength of galvanized wire make it well-suited for these applications, as it can withstand the elements and provide long-lasting protection.

Another popular application of galvanized wire is in the manufacturing of wire products, such as wire mesh, wire rope, and wire baskets. The corrosion-resistant properties of galvanized wire make it an ideal choice for these applications, as it helps to extend the life of the products and maintain their appearance.

Overall, galvanized wire is a versatile and cost-effective option for a wide range of applications. Its durability, strength, and resistance to corrosion make it an ideal choice for outdoor and industrial applications where reliability is key. Whether you are building a fence, reinforcing a concrete structure, or manufacturing wire products, galvanized wire is a reliable and long-lasting option that will meet your needs.

How to Choose the Right Wet Type Water Tank Wire Drawing Machine for Your Business

When it comes to choosing the right wet type water tank wire drawing machine for your business, there are several factors to consider. One of the most important considerations is the type of wire you will be working with. Galvanized wire and copper wire are two common types of wire used in various industries, and each requires a different type of wire drawing machine.

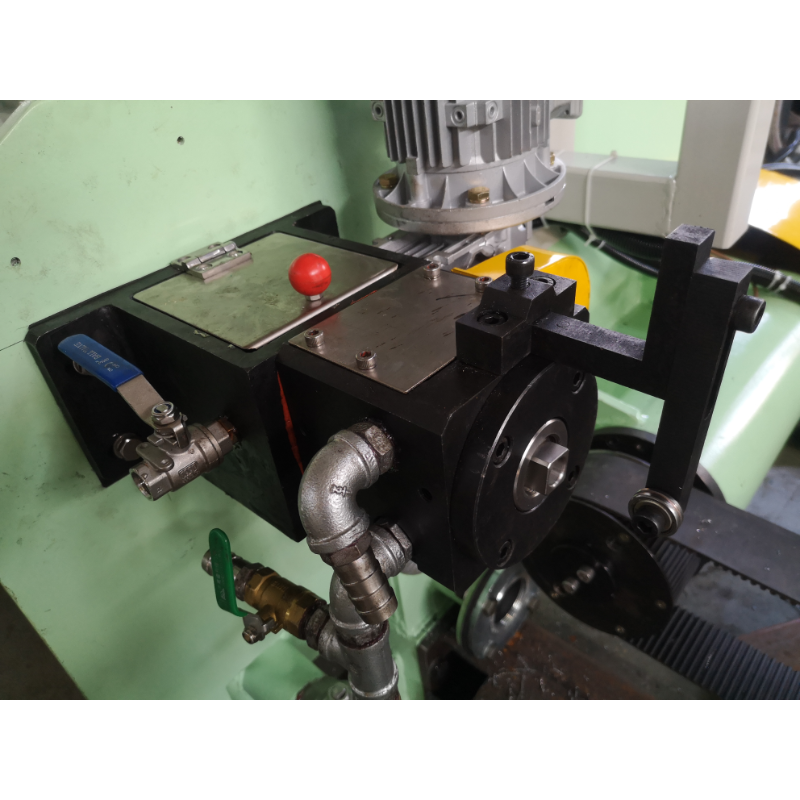

Galvanized wire is coated with a layer of zinc to protect it from corrosion, making it ideal for outdoor applications or environments with high humidity. When choosing a Copper Wire Drawing Machine for Rod Breakdown Machine, it is important to look for a machine that is specifically designed to handle the unique properties of this type of wire. The machine should have a durable construction and be able to withstand the corrosive effects of the zinc coating.

Copper wire, on the other hand, is known for its high conductivity and is often used in electrical applications. When selecting a Slip Type Wire Drawing Machine For Copper Wire, it is important to choose a machine that is capable of handling the softness and malleability of copper. The machine should have the appropriate speed and tension controls to ensure that the wire is drawn smoothly and without any damage to its surface.

In addition to considering the type of wire you will be working with, it is also important to think about the size and capacity of the wire drawing machine. The machine should be able to accommodate the diameter and length of the wire you will be processing, as well as the volume of wire you will be producing. It is important to choose a machine that is not only capable of handling your current needs but also has the capacity to grow with your business in the future.

Another important factor to consider when choosing a wet type water tank wire drawing machine is the level of automation and control it offers. Some machines come with advanced features such as computerized controls, automatic tension adjustment, and real-time monitoring of production parameters. These features can help improve efficiency, reduce downtime, and ensure consistent quality in your wire drawing process.

When evaluating different wire drawing machines, it is also important to consider the reputation and reliability of the manufacturer. Look for a company with a proven track record of producing high-quality machines and providing excellent customer support. Reading reviews and testimonials from other customers can also help you gauge the performance and reliability of a particular machine.

In conclusion, choosing the right wet type water tank wire drawing machine for your business requires careful consideration of the type of wire you will be working with, the size and capacity of the machine, the level of automation and control it offers, and the reputation of the manufacturer. By taking the time to research and evaluate your options, you can ensure that you select a machine that meets your specific needs and helps you achieve your production goals.