Table of Contents

Step-by-Step Guide to Setting Up a Wire Enameling Plant for Efficient Production

Setting up a wire enameling plant can be a complex process, but with the right guidance and planning, it can be a highly efficient and profitable venture. In this step-by-step guide, we will walk you through the process of setting up a wire enameling plant for efficient production.

The first step in setting up a wire enameling plant is to conduct thorough research on the market demand for enameled wire. Understanding the market trends and demand for enameled wire will help you determine the size and scale of your plant. It is essential to have a clear understanding of your target market and the specific requirements of your customers.

Once you have a clear understanding of the market demand, the next step is to choose a suitable location for your wire enameling plant. The location of your plant will have a significant impact on its efficiency and profitability. It is essential to choose a location that is easily accessible to raw materials and transportation networks. Additionally, the location should have access to a skilled workforce and be compliant with local regulations and zoning laws.

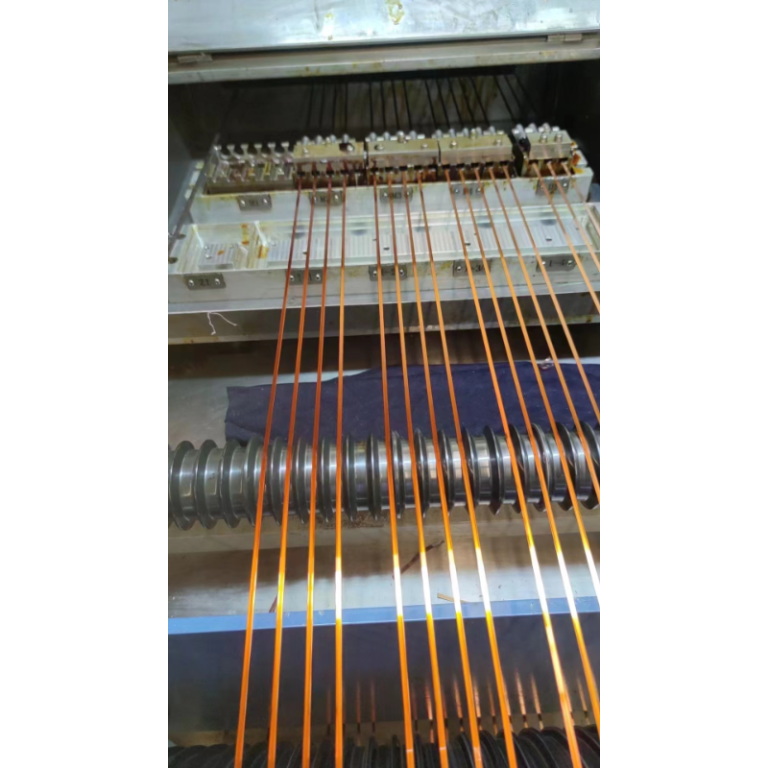

After selecting a suitable location, the next step is to design the layout of your wire Enameling Machine. The layout of your plant should be designed to maximize efficiency and productivity. It is essential to consider factors such as the flow of materials, equipment placement, and workflow optimization. A well-designed layout will help streamline production processes and reduce operational costs.

Once the layout of your wire enameling plant is finalized, the next step is to procure the necessary equipment and machinery. The equipment required for a wire enameling plant includes wire drawing machines, enameling machines, curing ovens, and quality control equipment. It is essential to choose high-quality equipment from reputable suppliers to ensure the efficiency and reliability of your plant.

After procuring the necessary equipment, the next step is to hire and train a skilled workforce. A well-trained workforce is essential for the efficient operation of your wire enameling plant. It is essential to provide comprehensive training to your employees on the operation of equipment, quality control procedures, and safety protocols. Additionally, it is crucial to create a positive work environment that promotes teamwork and collaboration.

Once your workforce is trained and ready, the next step is to start production at your wire enameling plant. It is essential to implement strict quality control measures to ensure the consistency and quality of your enameled wire. Regular quality checks and inspections should be conducted throughout the production process to identify and address any issues promptly.

As your wire enameling plant begins production, it is essential to monitor and analyze key performance indicators to track the efficiency and profitability of your plant. Key performance indicators such as production output, equipment downtime, and material wastage should be regularly monitored to identify areas for improvement and optimization.

In conclusion, setting up a wire enameling plant for efficient production requires careful planning, research, and execution. By following this step-by-step guide, you can establish a successful wire enameling plant that meets market demand and delivers high-quality enameled wire. With the right strategy and dedication, your wire enameling plant can become a profitable and sustainable business venture.

Benefits of Implementing a Wire Enameling Plant in Your Manufacturing Process

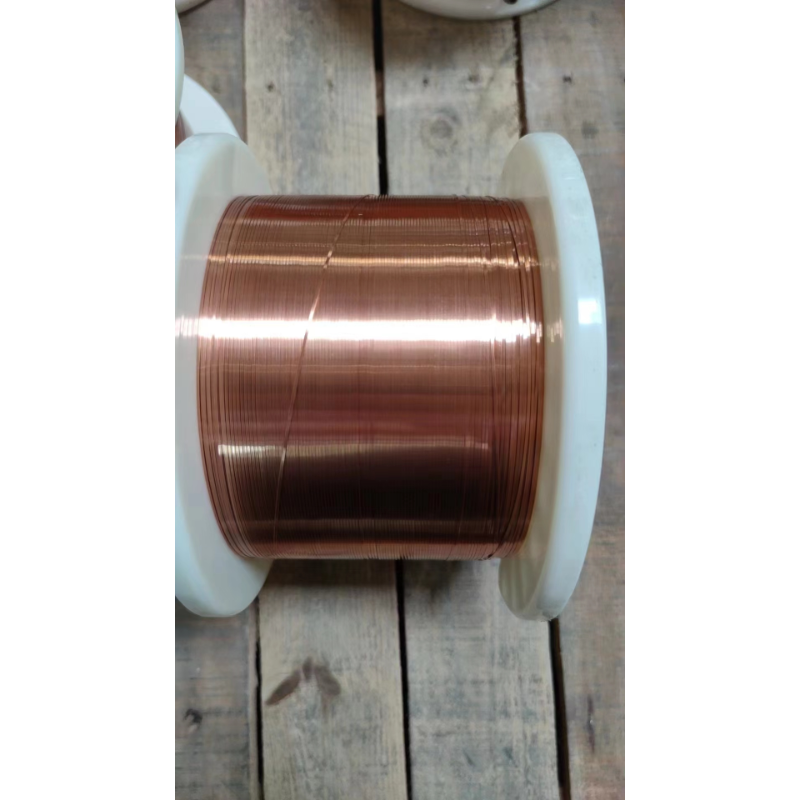

Wire enameling is a process that involves coating a wire with a thin layer of insulation to protect it from corrosion and wear. This process is essential in various industries, including electronics, automotive, and telecommunications. Implementing a wire enameling plant in your manufacturing process can bring numerous benefits to your business.

One of the primary advantages of having a wire enameling plant is the improved quality of the final product. The enamel coating provides a protective barrier that prevents the wire from being damaged by external factors such as moisture, heat, and chemicals. This results in a longer lifespan for the wire, reducing the need for frequent replacements and repairs.

In addition to enhancing the durability of the wire, Enameling Coating Machine also improves its electrical properties. The insulation provided by the enamel coating helps to prevent electrical leakage and short circuits, ensuring that the wire performs efficiently and safely. This is particularly important in industries where reliable electrical connections are crucial, such as in the production of electronic devices and appliances.

Another benefit of implementing a wire enameling plant is the increased efficiency of the manufacturing process. Enameling the wire in-house allows you to have better control over the quality and consistency of the coating, resulting in fewer defects and wastage. This can lead to cost savings in the long run, as you will not have to deal with the expenses associated with rework and scrap materials.

Furthermore, having a wire enameling plant can also help to streamline your production process. By integrating enameling into your manufacturing line, you can reduce the number of steps required to produce a finished product, saving time and resources. This can lead to faster turnaround times and increased productivity, allowing you to meet customer demands more effectively.

Implementing a wire enameling plant can also give you a competitive edge in the market. By offering high-quality, durable wires that are resistant to environmental factors, you can attract more customers and build a reputation for reliability and excellence. This can help you to stand out from your competitors and secure more business opportunities in the long term.

Moreover, having a wire enameling plant can also help you to comply with industry standards and regulations. Many industries have strict requirements for the quality and safety of electrical components, and using enameled wires that meet these standards can help you to ensure compliance. This can help you to avoid costly fines and penalties, as well as build trust with your customers and partners.

In conclusion, implementing a wire enameling plant in your manufacturing process can bring a wide range of benefits to your business. From improving the quality and durability of your products to increasing efficiency and competitiveness, enameling can help you to enhance your operations and achieve long-term success. If you are looking to take your manufacturing process to the next level, consider investing in a wire enameling plant today.