Table of Contents

Tips for Maintaining High Speed Copper Wire Drawing Machine

Maintaining a high-speed copper wire drawing machine is essential to ensure its optimal performance and longevity. These machines are used in various industries for drawing copper wires to the desired thickness and quality. Proper maintenance practices can help prevent breakdowns, reduce downtime, and extend the machine’s lifespan. In this article, we will discuss some tips for maintaining a high-speed copper wire drawing machine.

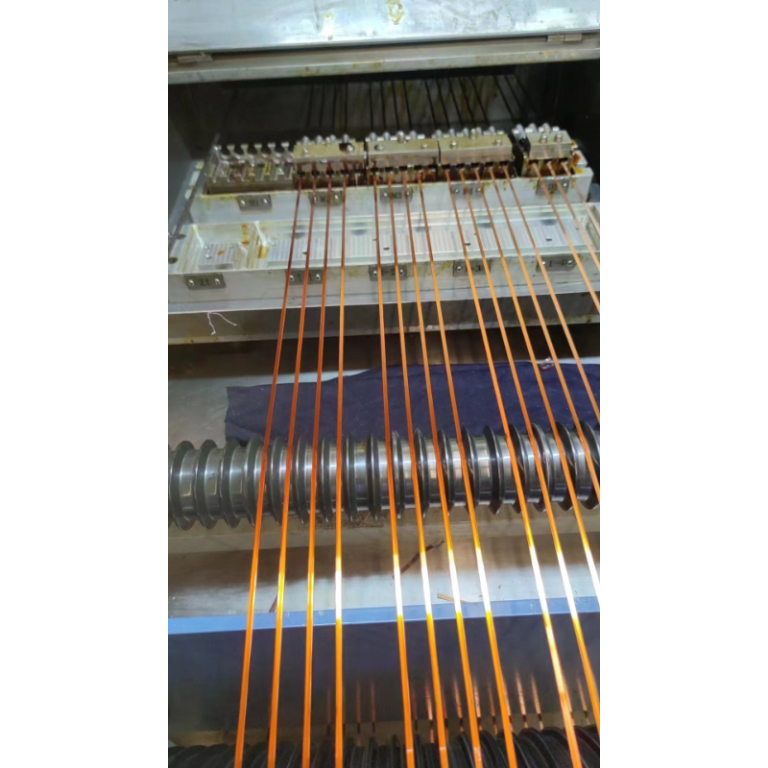

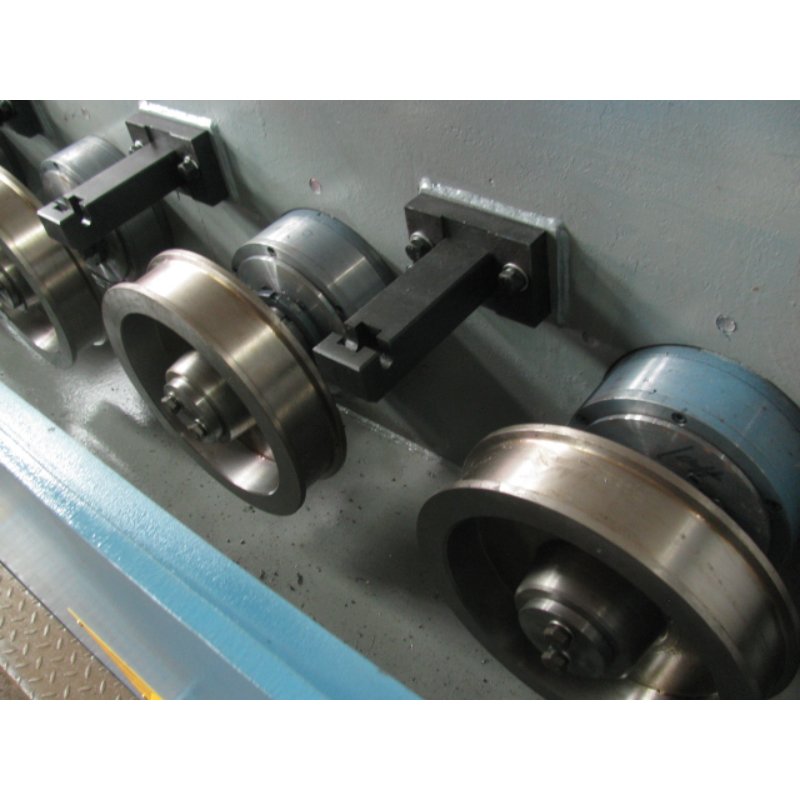

Regular cleaning and lubrication are crucial for the smooth operation of a Copper Wire Drawing Machine for Rod Breakdown Machine. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues. Additionally, lubricating the moving parts with a suitable lubricant can reduce friction and ensure smooth operation.

Inspecting the machine’s components regularly is another important maintenance tip. Check for any signs of wear or damage, such as worn-out bearings, cracked belts, or loose connections. Replace any damaged parts immediately to prevent further damage to the machine. Regular inspections can help identify potential issues early on and prevent costly repairs down the line.

Calibrating the machine regularly is essential for maintaining its accuracy and efficiency. Over time, the machine’s settings may drift, leading to deviations in wire thickness or quality. Calibrating the machine according to the manufacturer’s specifications can help ensure consistent performance and high-quality output. It is recommended to calibrate the machine at least once a month or as needed based on the production volume.

Monitoring the machine’s performance is also crucial for maintaining its high speed and efficiency. Keep track of key performance indicators, such as production rate, wire quality, and energy consumption. Any deviations from the normal operating parameters should be investigated promptly to identify the root cause and take corrective actions. Monitoring the machine’s performance can help optimize its operation and prevent unexpected breakdowns.

Training the machine operators on proper usage and maintenance practices is essential for ensuring the machine’s longevity. Provide comprehensive training to the operators on how to operate the machine safely and efficiently. Emphasize the importance of following the manufacturer’s guidelines for maintenance and troubleshooting. Proper training can help prevent operator errors and ensure the machine’s optimal performance.

In conclusion, maintaining a high-speed copper wire drawing machine requires regular cleaning, lubrication, inspection, calibration, monitoring, and operator training. By following these tips, you can ensure that your machine operates at its peak performance and delivers high-quality copper wires consistently. Remember that preventive maintenance is key to avoiding costly repairs and downtime. Invest time and effort in maintaining your copper wire drawing machine to maximize its lifespan and productivity.

Benefits of Using High Speed Copper Wire Drawing Machine

Copper wire drawing machines are essential equipment in the manufacturing industry, especially in the production of electrical wires and cables. These machines are used to reduce the diameter of copper wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. High-speed copper wire drawing machines offer several benefits that make them a valuable investment for businesses looking to improve their production efficiency and quality.

One of the key benefits of using a high-speed Copper Wire Drawing Machine Process is increased productivity. These machines are designed to operate at faster speeds, allowing for higher output levels compared to traditional wire drawing machines. This means that manufacturers can produce more wire in a shorter amount of time, leading to increased efficiency and profitability. Additionally, high-speed copper wire drawing machines are equipped with advanced features such as automatic tension control and lubrication systems, further enhancing productivity and reducing downtime.

Another advantage of high-speed copper wire drawing machines is improved wire quality. The high-speed operation of these machines results in a smoother surface finish and more precise diameter control, leading to higher quality wire products. This is particularly important in industries where wire quality is critical, such as in the production of electrical cables for power transmission or telecommunications. By using a high-speed copper wire drawing machine, manufacturers can ensure that their wire meets the required specifications and standards, leading to greater customer satisfaction and trust.

In addition to productivity and quality benefits, high-speed copper wire drawing machines also offer cost savings for manufacturers. The increased output levels and improved efficiency of these machines result in lower production costs per unit of wire, leading to overall cost savings for businesses. Furthermore, the advanced features of high-speed copper wire drawing machines, such as energy-efficient motors and automatic lubrication systems, help reduce energy consumption and maintenance costs, further contributing to cost savings in the long run.

Moreover, high-speed copper wire drawing machines are versatile and can be used for a wide range of wire sizes and materials. This flexibility allows manufacturers to adapt to changing market demands and produce a variety of wire products to meet customer needs. Whether it is fine gauge wire for electronics or heavy-duty wire for construction, high-speed copper wire drawing machines can handle a wide range of wire sizes and materials with ease, making them a versatile and valuable asset for businesses.

Overall, the benefits of using a high-speed copper wire drawing machine are clear. From increased productivity and improved wire quality to cost savings and versatility, these machines offer a range of advantages that can help manufacturers enhance their production processes and stay competitive in the market. By investing in a high-speed copper wire drawing machine, businesses can improve their efficiency, quality, and profitability, making it a worthwhile investment for the future.