Table of Contents

Maintenance Tips for Horizontal Enameling Machine

Horizontal enameling machines are essential tools in the manufacturing industry for applying enamel coatings to various products. These machines are designed to provide a smooth and even coating of enamel on a horizontal surface, ensuring a high-quality finish. To maintain the efficiency and longevity of a horizontal enameling machine, it is crucial to follow proper maintenance procedures. In this article, we will discuss some essential maintenance tips for horizontal enameling machines.

One of the most important maintenance tasks for a horizontal Enameling Machine for Aluminum Wire is regular cleaning. Over time, dirt, dust, and enamel residue can build up on the machine’s components, leading to decreased performance and potential damage. To prevent this, it is recommended to clean the machine after each use. Use a soft cloth or brush to remove any debris from the machine’s surface and components. Additionally, make sure to clean the enamel reservoir and nozzles to prevent clogs and ensure a consistent coating.

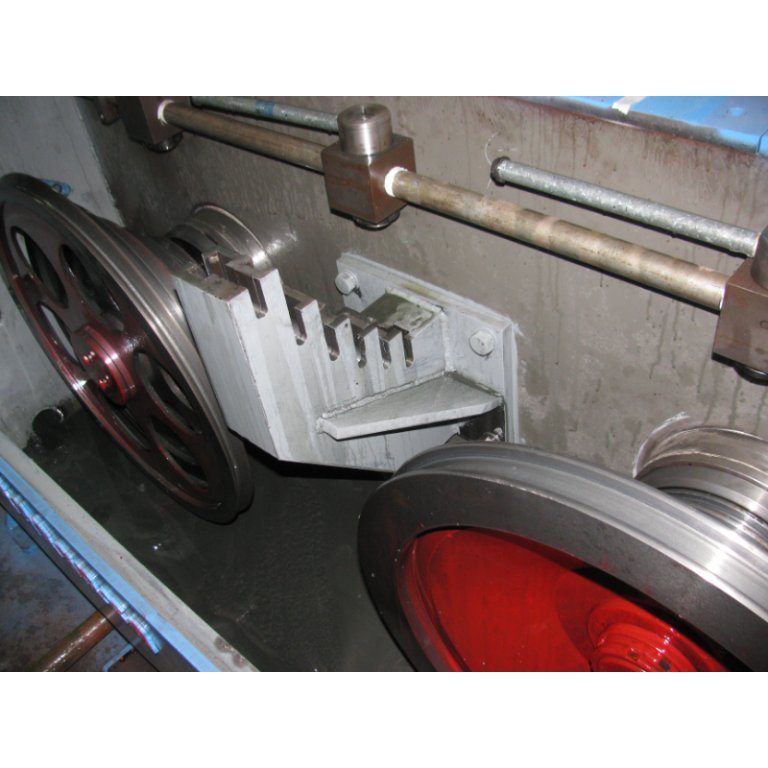

In addition to regular cleaning, it is essential to inspect the machine for any signs of wear or damage. Check the machine’s moving parts, such as rollers and conveyor belts, for any signs of wear or misalignment. Replace any worn or damaged parts immediately to prevent further damage to the machine. It is also important to check the machine’s electrical components, such as wiring and connections, for any signs of damage or corrosion. Regular inspections can help identify potential issues before they escalate into major problems.

Another crucial maintenance task for horizontal enameling machines is lubrication. Proper lubrication of the machine’s moving parts is essential to ensure smooth operation and prevent premature wear. Use a high-quality lubricant recommended by the machine’s manufacturer and apply it to the machine’s moving parts according to the manufacturer’s instructions. Regular lubrication can help extend the life of the machine and prevent costly repairs.

In addition to regular cleaning, inspection, and lubrication, it is important to calibrate the machine regularly. Calibration ensures that the machine is applying the enamel coating evenly and accurately, resulting in a high-quality finish. Follow the manufacturer’s guidelines for calibrating the machine, and make any necessary adjustments to ensure optimal performance. Regular calibration can help maintain the machine’s efficiency and consistency in coating application.

Lastly, it is important to store the horizontal enameling machine properly when not in use. Store the machine in a clean, dry, and well-ventilated area to prevent dust and debris from accumulating on the machine’s components. Cover the machine with a protective cover to prevent damage from moisture or sunlight. Proper storage can help prolong the life of the machine and prevent unnecessary wear and tear.

In conclusion, proper maintenance of a horizontal enameling machine is essential to ensure its efficiency and longevity. Regular cleaning, inspection, lubrication, calibration, and proper storage are key maintenance tasks that can help prevent costly repairs and downtime. By following these maintenance tips, you can keep your horizontal enameling machine in top condition and ensure a high-quality finish on your products.

Advantages of Using a Horizontal Enameling Machine

Enameling is a process that involves applying a protective coating of enamel to a metal surface to enhance its durability and aesthetic appeal. One of the most efficient ways to enamel metal objects is by using a horizontal enameling machine. This machine offers a range of advantages that make it a popular choice for manufacturers and artisans alike.

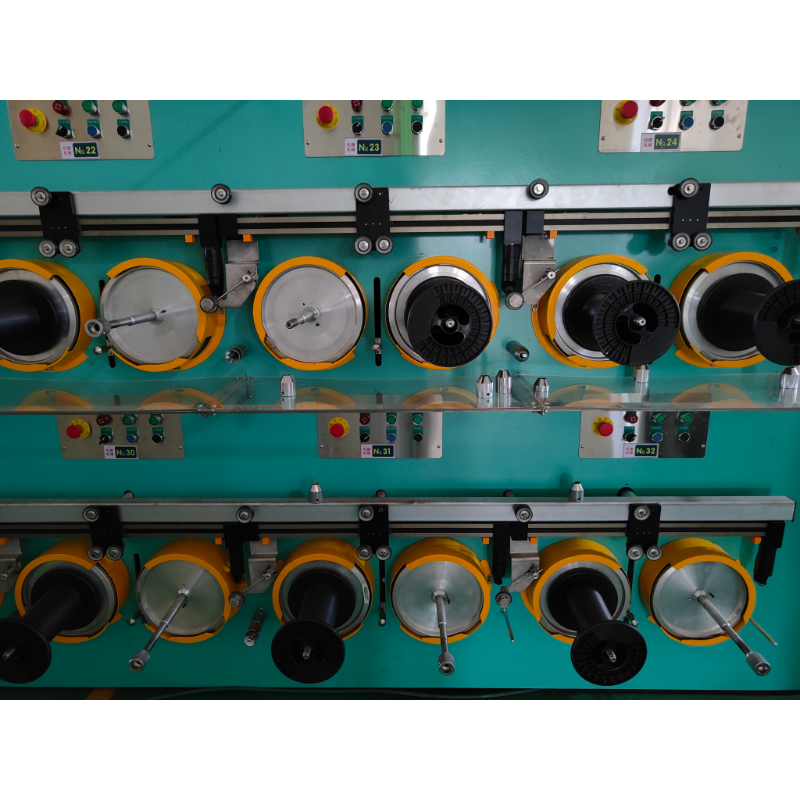

One of the key advantages of using a horizontal enameling machine is its ability to provide consistent and uniform coating thickness. This is essential for ensuring the quality and durability of the enamel finish. The machine is equipped with precise controls that allow users to adjust the thickness of the enamel coating according to their specific requirements. This level of control helps to eliminate inconsistencies and imperfections in the finished product, resulting in a high-quality enamel finish every time.

Another advantage of using a horizontal enameling machine is its efficiency and productivity. The machine is designed to handle large volumes of metal objects quickly and efficiently, making it ideal for mass production. Its horizontal design allows for easy loading and unloading of metal objects, reducing downtime and increasing productivity. Additionally, the machine’s automated processes help to streamline the enameling process, saving time and labor costs.

In addition to its efficiency and productivity, a horizontal Wire Enameling Plant also offers versatility in terms of the types of metal objects it can enamel. The machine is capable of handling a wide range of metal shapes and sizes, making it suitable for a variety of applications. Whether you are enameling small jewelry pieces or large industrial components, a horizontal enameling machine can accommodate your needs.

Furthermore, a horizontal enameling machine is easy to operate and maintain. The machine is equipped with user-friendly controls that make it simple to adjust settings and monitor the enameling process. Additionally, the machine’s durable construction and high-quality components ensure reliable performance and minimal downtime. Regular maintenance and cleaning of the machine are straightforward, helping to prolong its lifespan and ensure consistent results.

One of the most significant advantages of using a horizontal enameling machine is its cost-effectiveness. The machine’s efficiency, productivity, and versatility help to reduce production costs and increase profitability. By streamlining the enameling process and minimizing waste, manufacturers can save time and resources while producing high-quality enamel finishes. Additionally, the machine’s durability and low maintenance requirements help to lower operating costs over time.

In conclusion, a horizontal enameling machine offers a range of advantages that make it an excellent choice for manufacturers and artisans looking to enamel metal objects efficiently and effectively. From its ability to provide consistent coating thickness to its versatility and cost-effectiveness, this machine is a valuable tool for enhancing the durability and aesthetic appeal of metal objects. Whether you are producing jewelry, industrial components, or decorative items, a horizontal enameling machine can help you achieve high-quality enamel finishes with ease.

How to Choose the Right Horizontal Enameling Machine for Your Business

Enameling is a process that involves applying a protective coating to metal surfaces to enhance their durability and appearance. Horizontal enameling machines are essential equipment for businesses that specialize in enameling metal products. These machines are designed to automate the enameling process, making it more efficient and cost-effective. However, choosing the right Vertical Enameling Machine for your business can be a daunting task, given the wide range of options available in the market.

When selecting a horizontal enameling machine, there are several factors that you need to consider to ensure that you make the right choice. One of the most important factors to consider is the size of the machine. The size of the machine should be determined by the size of the metal products that you will be enameling. If you are enameling small metal products, a smaller machine will suffice. However, if you are enameling larger metal products, you will need a larger machine to accommodate the size of the products.

Another important factor to consider when choosing a horizontal enameling machine is the type of enameling process that you will be using. There are two main types of enameling processes: wet enameling and dry enameling. Wet enameling involves applying a liquid enamel to the metal surface and then firing it in a kiln to cure the enamel. Dry enameling, on the other hand, involves applying a powdered enamel to the metal surface and then firing it in a kiln to cure the enamel. The type of enameling process that you will be using will determine the type of machine that you need.

In addition to the size and type of enameling process, you also need to consider the features and capabilities of the horizontal enameling machine. Some machines come with advanced features such as programmable controls, automatic temperature control, and multiple firing zones. These features can help you achieve consistent and high-quality enameling results. However, these advanced features come at a higher cost, so you need to weigh the benefits against the cost to determine if they are worth it for your business.

Furthermore, you need to consider the production capacity of the horizontal enameling machine. The production capacity of the machine should be able to meet the demands of your business. If you have a high volume of metal products that need to be enameled, you will need a machine with a higher production capacity. On the other hand, if you have a lower volume of metal products, a machine with a lower production capacity will suffice.

When choosing a horizontal enameling machine, it is also important to consider the reputation and reliability of the manufacturer. You should choose a manufacturer that has a good reputation for producing high-quality machines that are reliable and durable. Reading reviews and testimonials from other customers can help you gauge the reputation of the manufacturer.

In conclusion, choosing the right horizontal enameling machine for your business is a crucial decision that can impact the quality and efficiency of your enameling process. By considering factors such as size, type of enameling process, features and capabilities, production capacity, and manufacturer reputation, you can make an informed decision that will benefit your business in the long run.