Table of Contents

Comparison of Different Models of Standard Rod Breakdown Drawing Machine

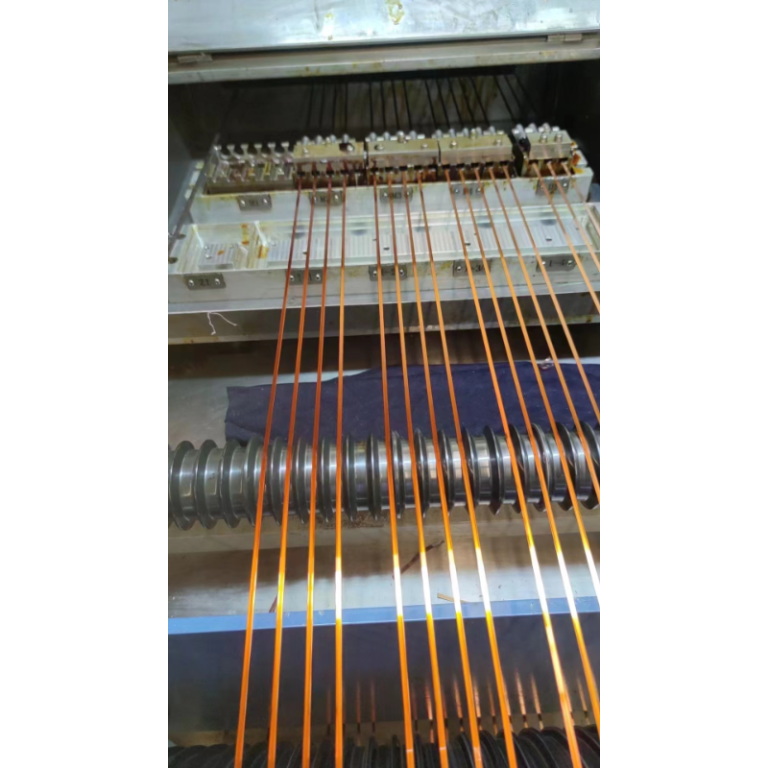

Standard Rod Breakdown Drawing Machines are essential equipment in the wire and cable industry, used to reduce the diameter of wire rods and increase their length. There are several models of these machines available in the market, each with its own unique features and capabilities. In this article, we will compare different models of Standard Rod Breakdown Drawing Machines to help you make an informed decision when choosing the right one for your business.

One of the most popular models of Standard Rod Breakdown Drawing Machines is the single-wire drawing machine. This machine is designed to process one wire at a time, making it ideal for small-scale operations or for companies that require high precision in their wire drawing process. The single-wire drawing machine is known for its simplicity and ease of use, making it a popular choice among manufacturers.

On the other hand, the multi-wire drawing machine is designed to process multiple wires simultaneously, increasing the productivity and efficiency of the wire drawing process. This machine is ideal for large-scale operations that require high output and fast processing times. The multi-wire drawing machine is equipped with multiple drawing dies, allowing it to process several wires at once without compromising on quality.

Another model of Aluminum Wire Drawing Machine. This machine is designed to continuously draw wire without the need for manual intervention, making it ideal for high-volume production lines. The continuous wire drawing machine is equipped with automatic controls and sensors that monitor the wire drawing process, ensuring consistent quality and reducing the risk of errors.

In addition to these models, there are also specialized Standard Rod Breakdown Drawing Machines available in the market, such as the high-speed wire drawing machine and the heavy-duty wire drawing machine. The high-speed wire drawing machine is designed to process wire at a faster rate, making it ideal for companies that require quick turnaround times. The heavy-duty wire drawing machine is designed to process thicker and stronger wires, making it suitable for industries that require heavy-duty wire products.

When choosing a Standard Rod Breakdown Drawing Machine for your business, it is important to consider factors such as the type of wire you will be processing, the volume of production, and the level of precision required. It is also important to consider the reputation of the manufacturer and the after-sales support provided.

In conclusion, Standard Rod Breakdown Drawing Machines are essential equipment in the wire and cable industry, and choosing the right model can have a significant impact on the efficiency and quality of your wire drawing process. By comparing different models of Standard Rod Breakdown Drawing Machines and considering your specific requirements, you can make an informed decision that will benefit your business in the long run.

Advantages of Using Standard Rod Breakdown Drawing Machine

Standard rod breakdown drawing machines are essential equipment in the wire and cable manufacturing industry. These machines are used to reduce the diameter of wire rods and produce various types of wire with different diameters. There are several advantages to using a standard rod breakdown drawing machine, which we will discuss in this article.

One of the main advantages of using a standard rod breakdown drawing machine is its ability to produce high-quality wire with consistent diameter and surface finish. These machines are equipped with precision tools and controls that ensure the wire is drawn evenly and smoothly, resulting in a uniform product. This is crucial for industries that require wire with specific dimensions and properties, such as the automotive and electronics industries.

Another advantage of using a standard rod breakdown drawing machine is its efficiency and productivity. These machines are designed to operate at high speeds and can process large quantities of wire rods in a short amount of time. This helps manufacturers meet production deadlines and reduce lead times, ultimately improving overall efficiency and profitability.

In addition to efficiency, Water-Tank Wire Drawing Machine For Aluminum Wire are also known for their durability and reliability. These machines are built to withstand heavy use and can operate continuously for long periods without experiencing breakdowns or malfunctions. This ensures that manufacturers can rely on their equipment to deliver consistent results day in and day out.

Furthermore, standard rod breakdown drawing machines are versatile and can be used to produce a wide range of wire products. Whether you need thin wire for electrical applications or thick wire for construction purposes, these machines can be adjusted to accommodate different wire diameters and materials. This flexibility allows manufacturers to meet the diverse needs of their customers and expand their product offerings.

Moreover, standard rod breakdown drawing machines are cost-effective investments for wire and cable manufacturers. While the initial cost of purchasing a machine may seem high, the long-term benefits far outweigh the upfront expenses. By increasing productivity, reducing waste, and improving product quality, these machines can help companies save money in the long run and achieve a higher return on investment.

Overall, standard rod breakdown drawing machines offer numerous advantages to wire and cable manufacturers. From producing high-quality wire with consistent dimensions to improving efficiency and productivity, these machines are essential for companies looking to stay competitive in the industry. With their durability, versatility, and cost-effectiveness, standard rod breakdown drawing machines are a valuable asset for any manufacturing operation.

Maintenance Tips for Standard Rod Breakdown Drawing Machine

A standard rod breakdown drawing machine for aluminum wire is a crucial piece of equipment in the wire and cable manufacturing industry. It is used to reduce the diameter of wire rods and draw them into various sizes of wire. To ensure the machine operates efficiently and effectively, regular maintenance is essential. In this article, we will discuss some maintenance tips for a standard rod breakdown drawing machine.

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, pulleys, and bearings. Replace any worn-out parts immediately to prevent further damage to the machine. Lubricate moving parts regularly to reduce friction and ensure smooth operation.

Another important maintenance tip is to clean the machine regularly. Dust, dirt, and debris can accumulate on the machine over time, causing it to malfunction. Use a soft brush or cloth to remove any buildup from the machine’s surfaces. Pay special attention to the wire guides and dies, as any debris in these areas can affect the quality of the drawn wire.

In addition to regular cleaning, it is important to calibrate the machine periodically. Check the tension settings, speed controls, and other parameters to ensure they are set correctly. Improper calibration can lead to uneven wire drawing and poor quality wire. Consult the machine’s manual for specific calibration instructions and follow them carefully.

Regularly inspect the electrical components of the machine, such as the motor, control panel, and wiring. Look for any signs of damage or overheating, and replace any faulty components immediately. Keep the electrical components clean and free of dust to prevent electrical malfunctions.

It is also important to monitor the machine’s performance regularly. Keep track of the wire diameter, speed, and tension settings to ensure they are within the specified range. Any deviations from the standard parameters could indicate a problem with the machine that needs to be addressed.

In addition to regular maintenance, it is important to train operators on how to use the machine properly. Provide training on safety procedures, maintenance tasks, and troubleshooting techniques. Encourage operators to report any issues or concerns with the machine promptly to prevent further damage.

Lastly, consider scheduling routine maintenance checks with a qualified technician. A professional inspection can help identify any potential issues with the machine before they escalate into major problems. A technician can also provide recommendations for improving the machine’s performance and longevity.

In conclusion, regular maintenance is essential for ensuring the efficient operation of a standard rod breakdown drawing machine. By following these maintenance tips, you can prolong the life of the machine, improve wire quality, and prevent costly repairs. Remember to inspect, clean, calibrate, monitor, train, and schedule routine maintenance checks to keep your machine running smoothly.