Table of Contents

How to Choose the Right Mechanical Enameling Machine for Your Business

Mechanical enameling machines are essential equipment for businesses in the enamel coating industry. These machines are used to apply a durable and attractive enamel coating to various metal surfaces, such as cookware, appliances, and automotive parts. If you are in the market for a mechanical enameling machine, there are several factors to consider to ensure that you choose the right machine for your business.

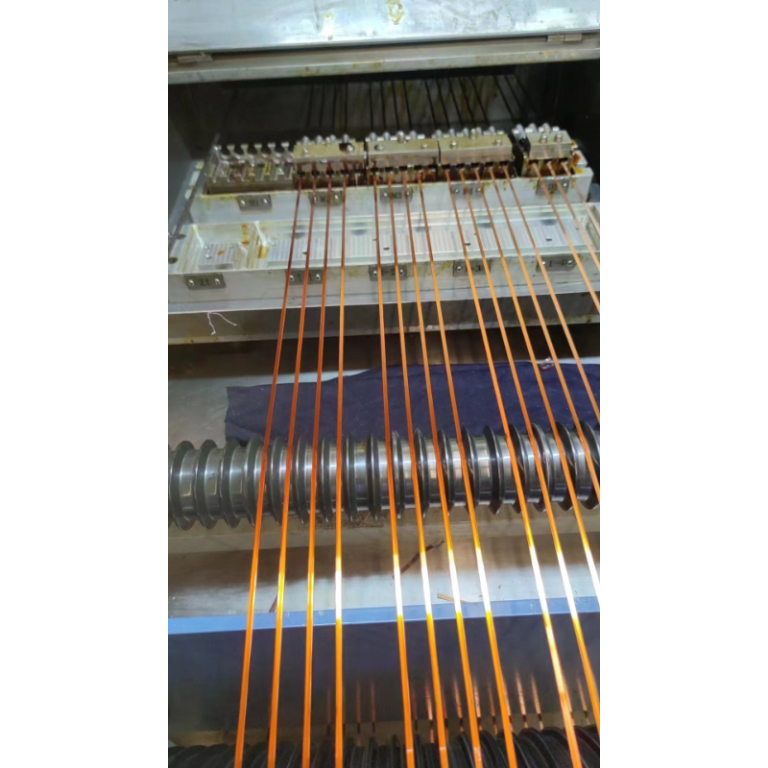

One of the most important factors to consider when choosing a mechanical Enameling Machine for Aluminum Wire is the size and capacity of the machine. The size of the machine will depend on the volume of products that you need to coat and the size of the parts that you will be coating. It is important to choose a machine that can accommodate the size and volume of your production needs to ensure that you can meet your production goals efficiently.

Another important factor to consider when choosing a mechanical enameling machine is the type of enamel coating that the machine is capable of applying. There are different types of enamel coatings available, such as wet enamel, dry enamel, and powder enamel. Each type of enamel coating has its own unique properties and application methods, so it is important to choose a machine that is compatible with the type of enamel coating that you will be using.

In addition to the size and type of Enameling Coating Machine, it is also important to consider the features and capabilities of the mechanical enameling machine. Some machines may have additional features, such as automatic loading and unloading systems, temperature control systems, and programmable settings. These features can help to improve the efficiency and quality of the coating process, so it is important to choose a machine that has the features that are most important to your business.

When choosing a mechanical enameling machine, it is also important to consider the reputation and reliability of the manufacturer. Look for a manufacturer that has a proven track record of producing high-quality machines that are durable and reliable. Reading customer reviews and testimonials can also help you to gauge the quality of the machine and the level of customer satisfaction.

Finally, it is important to consider the cost of the mechanical enameling machine. Prices can vary widely depending on the size, features, and capabilities of the machine, so it is important to set a budget and choose a machine that fits within your budget while still meeting your production needs.

In conclusion, choosing the right mechanical enameling machine for your business is a crucial decision that can have a significant impact on the efficiency and quality of your production process. By considering factors such as size, type of enamel coating, features, manufacturer reputation, and cost, you can ensure that you choose a machine that meets your production needs and helps your business succeed in the enamel coating industry.

Benefits of Investing in Mechanical Enameling Machines for Sale

Mechanical enameling machines are a crucial piece of equipment for any industrial operation that requires the application of enamel coatings to metal surfaces. These machines offer a wide range of benefits that make them a worthwhile investment for businesses looking to improve their efficiency and productivity.

One of the key benefits of investing in mechanical Enameling Machine for Copper Wire is their ability to apply enamel coatings quickly and evenly. These machines are designed to automate the enameling process, ensuring that each metal surface receives a consistent and uniform coating. This not only improves the quality of the finished product but also reduces the amount of time and labor required to complete the job.

In addition to their speed and efficiency, mechanical enameling machines are also highly versatile. They can be used to apply a wide range of enamel coatings, including both liquid and powder enamels. This flexibility allows businesses to customize their enameling process to meet the specific needs of their products, whether they require a glossy finish, a matte finish, or a textured finish.

Another benefit of investing in mechanical enameling machines is their durability and reliability. These machines are built to withstand the rigors of industrial use, ensuring that they will continue to perform consistently and reliably over time. This reduces the risk of downtime and maintenance costs, allowing businesses to maximize their production output and minimize disruptions to their operations.

Furthermore, mechanical enameling machines are easy to operate and maintain. Most machines come with user-friendly controls and interfaces that make them simple to set up and operate, even for operators with limited experience. Additionally, these machines are designed to be easy to clean and maintain, reducing the amount of time and effort required to keep them in good working condition.

Investing in mechanical enameling machines can also help businesses reduce their environmental impact. These machines are designed to minimize waste and emissions, making them a more sustainable option for businesses looking to reduce their carbon footprint. By using less enamel and producing less waste, businesses can lower their overall environmental impact and contribute to a more sustainable future.

Overall, investing in mechanical enameling machines for sale offers a wide range of benefits for businesses looking to improve their efficiency, productivity, and sustainability. These machines offer fast and consistent enamel application, versatility in coating options, durability and reliability, ease of operation and maintenance, and environmental benefits. By choosing to invest in mechanical enameling machines, businesses can streamline their enameling process, improve the quality of their products, and reduce their environmental impact, making them a valuable asset for any industrial operation.