Table of Contents

Step-by-Step Guide on How to Operate an Enameling Machine

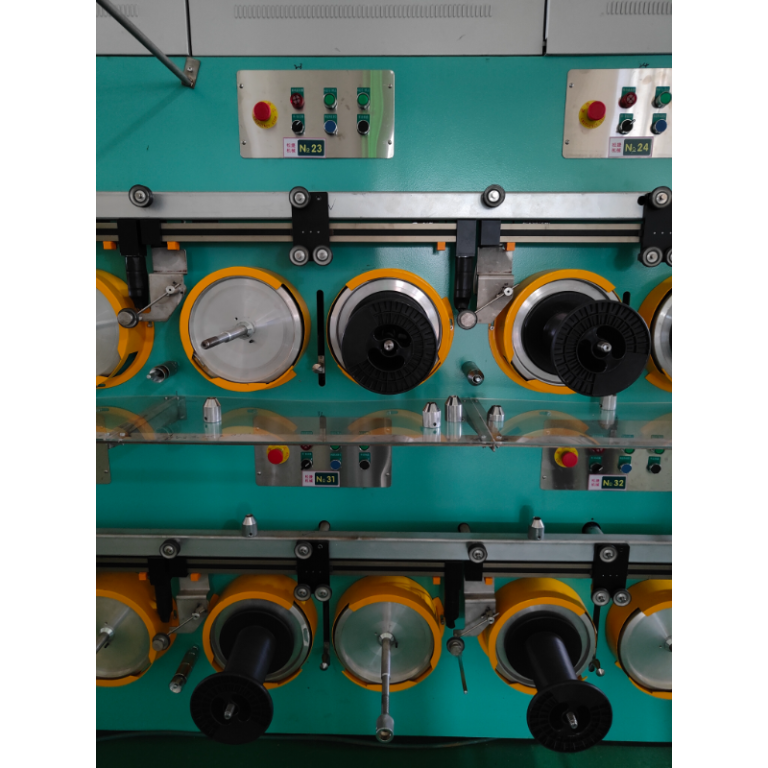

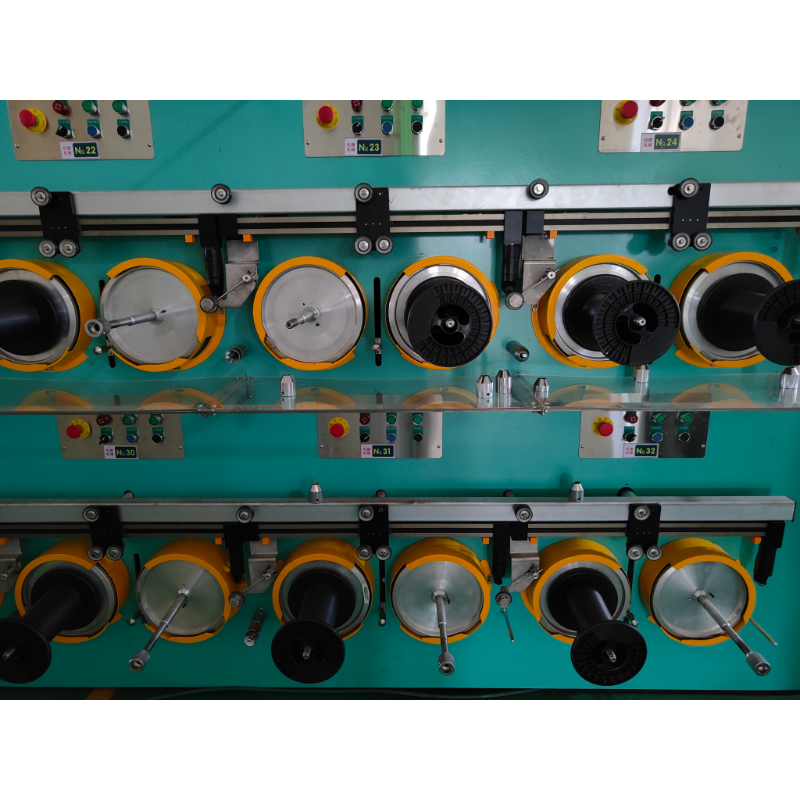

An online drawing enameling machine is a sophisticated piece of equipment used in the manufacturing industry to apply a protective enamel coating to metal wires. This process helps to improve the durability and longevity of the wires, making them suitable for a wide range of applications. Operating an online drawing enameling machine requires precision and attention to detail to ensure that the enamel coating is applied evenly and effectively. In this article, we will provide a step-by-step guide on how to operate an online drawing enameling machine.

The first step in operating an on line drawing enameling machine is to ensure that the machine is properly set up and calibrated. This includes checking that the wire feed system is functioning correctly, the enamel coating system is properly primed, and the temperature and speed settings are adjusted to the desired levels. It is important to follow the manufacturer’s instructions carefully to ensure that the machine is set up correctly.

Once the machine is set up, the next step is to feed the metal wire through the machine. This is done by placing the wire on the wire feed system and adjusting the tension to ensure a smooth and even feed. It is important to monitor the wire feed system closely to ensure that the wire is being fed at the correct speed and tension to prevent any issues with the enamel coating process.

After the wire is fed through the machine, the next step is to apply the enamel coating. This is done by passing the wire through a series of enamel application chambers, where the enamel is applied to the surface of the wire. It is important to ensure that the enamel is applied evenly and consistently to prevent any issues with the final coating.

Once the enamel coating is applied, the wire is then passed through a series of heating chambers to cure the enamel. This process helps to ensure that the enamel coating is properly bonded to the surface of the wire and provides a durable and long-lasting finish. It is important to monitor the temperature and speed settings during the curing process to ensure that the enamel coating is cured properly.

After the enamel coating is cured, the final step is to inspect the wire for any defects or imperfections. This includes checking for any uneven coating, bubbles, or other issues that may affect the quality of the wire. It is important to inspect the wire carefully and make any necessary adjustments to ensure that the enamel coating is applied correctly.

In conclusion, operating an online drawing enameling machine requires precision and attention to detail to ensure that the enamel coating is applied evenly and effectively. By following the steps outlined in this article, you can ensure that your online drawing enameling machine operates smoothly and produces high-quality enamel-coated wires for a wide range of applications.

Benefits of Using an Enameling Machine for Jewelry Making

In the world of jewelry making, precision and efficiency are key factors in creating high-quality pieces. One tool that has revolutionized the process of enameling jewelry is the online drawing enameling machine. This innovative machine offers a range of benefits that make it a valuable asset for jewelry makers looking to streamline their production process and create stunning pieces with ease.

One of the primary benefits of using an Enameling Wire Production Line is its ability to produce intricate designs with precision and accuracy. Traditional enameling techniques often require a steady hand and a high level of skill to achieve detailed designs. With an online drawing enameling machine, jewelry makers can easily create complex patterns and designs with the click of a button. This not only saves time but also ensures that each piece is consistent and flawless.

Another advantage of using an online drawing enameling machine is its speed and efficiency. Traditional enameling methods can be time-consuming and labor-intensive, requiring multiple steps and processes to achieve the desired result. With an online drawing enameling machine, jewelry makers can significantly reduce the time it takes to enamel their pieces, allowing them to produce more jewelry in less time. This increased efficiency can lead to higher productivity and ultimately, higher profits for jewelry makers.

In addition to its precision and efficiency, an online drawing enameling machine also offers versatility in design. Jewelry makers can easily customize their designs and experiment with different patterns, colors, and textures to create unique and one-of-a-kind pieces. This flexibility allows for greater creativity and innovation in jewelry making, giving artists the freedom to explore new techniques and styles.

Furthermore, an online drawing enameling machine is user-friendly and easy to operate, making it accessible to both experienced jewelry makers and beginners. The machine comes equipped with a user-friendly interface that allows users to upload their designs, adjust settings, and control the enameling process with ease. This simplicity makes it easy for jewelry makers to learn how to use the machine quickly and start creating beautiful pieces in no time.

Overall, the benefits of using an online drawing enameling machine for jewelry making are clear. From its precision and efficiency to its versatility and user-friendly design, this innovative tool offers a range of advantages that can help jewelry makers take their craft to the next level. Whether you are a seasoned professional looking to streamline your production process or a beginner eager to explore the world of enameling, an online drawing enameling machine is a valuable investment that can enhance your jewelry making experience and elevate your creations to new heights.