Table of Contents

Step-by-Step Guide on How to Properly Maintain and Clean Enameling Wire Stripper Machine

Enameling wire stripper machines are essential tools for efficiently removing the enamel coating from wires. To ensure that your machine continues to function properly and efficiently, it is important to regularly maintain and clean it. Proper maintenance and cleaning will not only extend the lifespan of your machine but also ensure that it continues to produce high-quality results. In this article, we will provide you with a step-by-step guide on how to properly maintain and clean your enameling wire stripper machine.

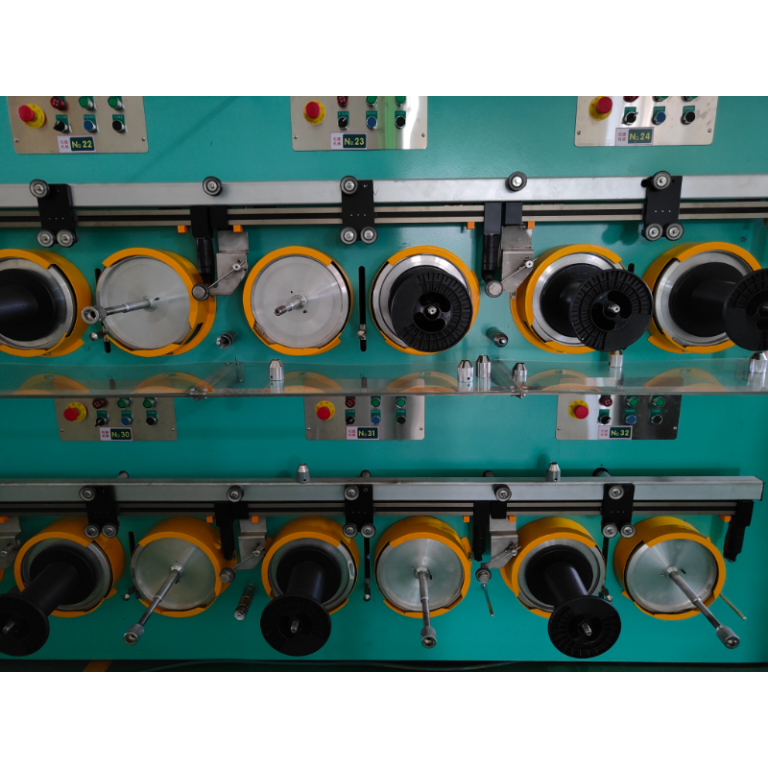

The first step in maintaining your Enameling Machine is to regularly inspect it for any signs of wear and tear. Check for any loose or damaged parts, such as blades or rollers, and replace them if necessary. It is also important to lubricate the moving parts of the machine to prevent friction and ensure smooth operation. Use a high-quality lubricant that is specifically designed for use with wire stripping machines.

Next, it is important to clean your enameling wire stripper machine regularly to remove any dirt, dust, or debris that may have accumulated on the machine. Start by unplugging the machine and removing any wires or cables that are attached to it. Use a soft brush or cloth to gently wipe down the exterior of the machine, paying special attention to the areas around the blades and rollers. Be sure to also clean the inside of the machine, removing any debris that may have built up in the stripping chamber.

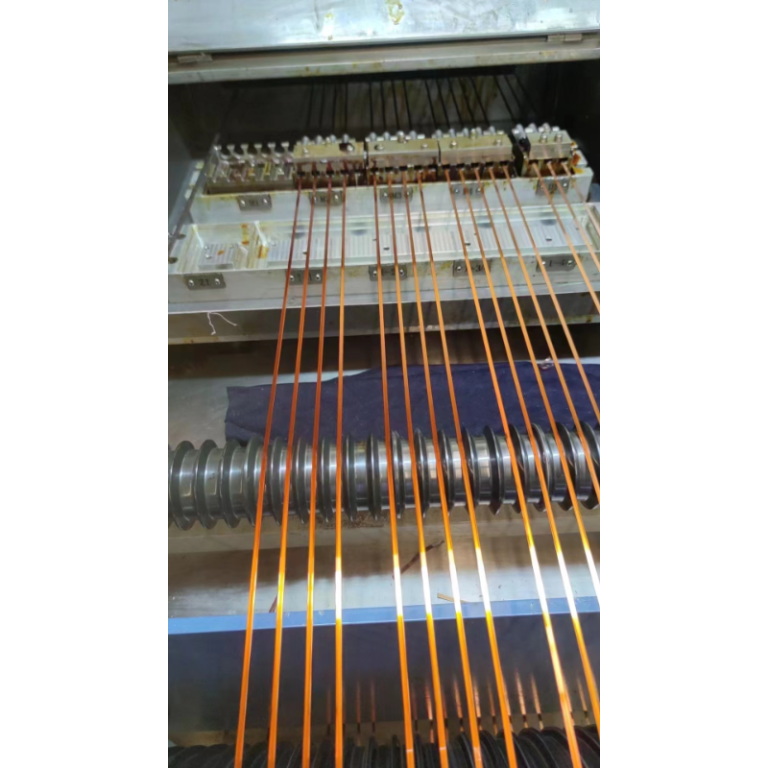

Once you have cleaned the machine, it is important to properly adjust the settings to ensure that it is stripping wires accurately and efficiently. Check the blade alignment and adjust it if necessary to ensure that it is cutting through the enamel coating without damaging the wire underneath. You should also check the tension settings on the machine to ensure that the wire is being fed through the machine smoothly and without any snags.

After adjusting the settings, it is important to test the machine to ensure that it is functioning properly. Feed a few wires through the machine and check the quality of the stripping. If you notice any issues, such as uneven stripping or damage to the wire, make the necessary adjustments to correct the problem.

In addition to regular maintenance and cleaning, it is also important to follow the manufacturer’s guidelines for the proper use of your enameling wire stripper machine. This includes using the machine only for its intended purpose and avoiding overloading it with wires that are too thick or too hard. It is also important to use the correct type and size of wire for the machine to ensure that it operates efficiently and produces high-quality results.

By following these steps and guidelines, you can ensure that your enameling wire stripper machine continues to function properly and efficiently. Regular maintenance and cleaning will not only extend the lifespan of your machine but also ensure that it continues to produce high-quality results. Proper adjustment of settings and adherence to manufacturer guidelines will also help to prevent damage to the machine and ensure that it operates safely. With proper care and maintenance, your enameling wire stripper machine will continue to be a valuable tool in your workshop for years to come.

Benefits of Using Enameling Wire Stripper Machine for Industrial Applications

Enameling wire stripper machines are essential tools in various industrial applications, offering a wide range of benefits that can significantly improve efficiency and productivity. These machines are specifically designed to remove the enamel coating from wires, allowing for easier handling and processing. In this article, we will explore the advantages of using enameling wire stripper machines in industrial settings.

One of the primary benefits of using Wire Enameling Plant is the time-saving aspect. These machines are capable of stripping the enamel coating from wires quickly and efficiently, reducing the amount of time and labor required for this task. This can lead to increased productivity and cost savings for industrial operations, as workers can focus on other important tasks while the machine handles the wire stripping process.

In addition to saving time, enameling wire stripper machines also offer a high level of precision and accuracy. These machines are designed to strip the enamel coating from wires without damaging the underlying metal, ensuring that the wires remain intact and ready for further processing. This level of precision is crucial in industrial applications where the quality of the wires is paramount, as any damage or imperfections can lead to costly rework or product defects.

Another key benefit of using enameling wire stripper machines is the consistency they provide in the wire stripping process. These machines are programmed to strip wires to a specific depth and width, ensuring that each wire is stripped uniformly. This level of consistency is essential in industrial applications where uniformity is critical, such as in the production of electrical components or wiring harnesses. By using enameling wire stripper machines, manufacturers can achieve a high level of consistency in their products, leading to improved quality and customer satisfaction.

Furthermore, enameling wire stripper machines are versatile tools that can handle a wide range of wire sizes and types. These machines are equipped with adjustable settings that allow them to strip wires of varying diameters and materials, making them suitable for a variety of industrial applications. Whether you are working with thin copper wires or thick aluminum cables, an enameling wire stripper machine can be easily adjusted to meet your specific needs.

In conclusion, enameling wire stripper machines offer a multitude of benefits for industrial applications. From saving time and labor to providing precision and consistency in the wire stripping process, these machines are essential tools for manufacturers looking to improve efficiency and productivity. With their versatility and ability to handle a wide range of wire sizes and types, enameling wire stripper machines are a valuable investment for any industrial operation.