Enameling Machine,Fine Wire Enameling Machine,Enameling Machine for Copper Wire

Main advanteges:

· Low power consumption

· Zero pollution of exhaust

Secondly catalyst with special recipe, affective at 320 °C and above only, without extra electrical heating, ensure a complete decontamination, equal to zero pollution of exhaust.

· Improvements of oven heat insulation

All insulating cottons adpot ceramic fiber material

Thicken heaters insulation zone at top of oven

· Alternate the position of capstan roller and applicator, the final coating pass go to spooler across lower wire cooler, reduce wire temperature on bobbin.

· Lubricant oil coated with flow control

· Management functions

Earthnet interface available for remote control

Detection, storing and collection of power consumption quantity and unit power consumption

· Wire temperature control

· Automatic boundary of traverse when winding up

· Self-bonding coating function optional

Hot Air Recirculation Enameling Machine,Heat Exchange Enamelling Machine,Horizontal High Speed Wire Enameling Machine

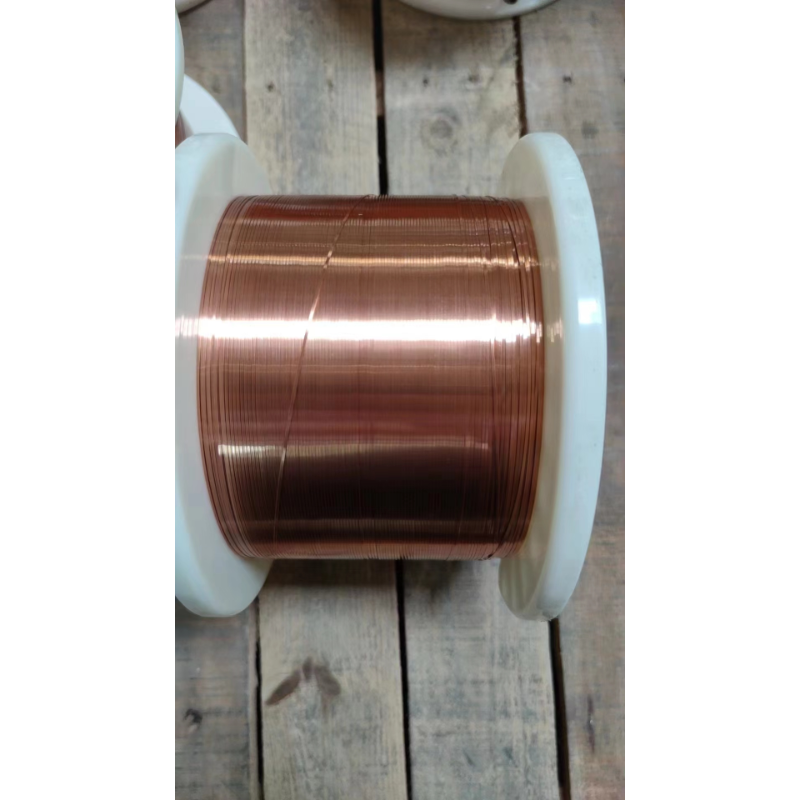

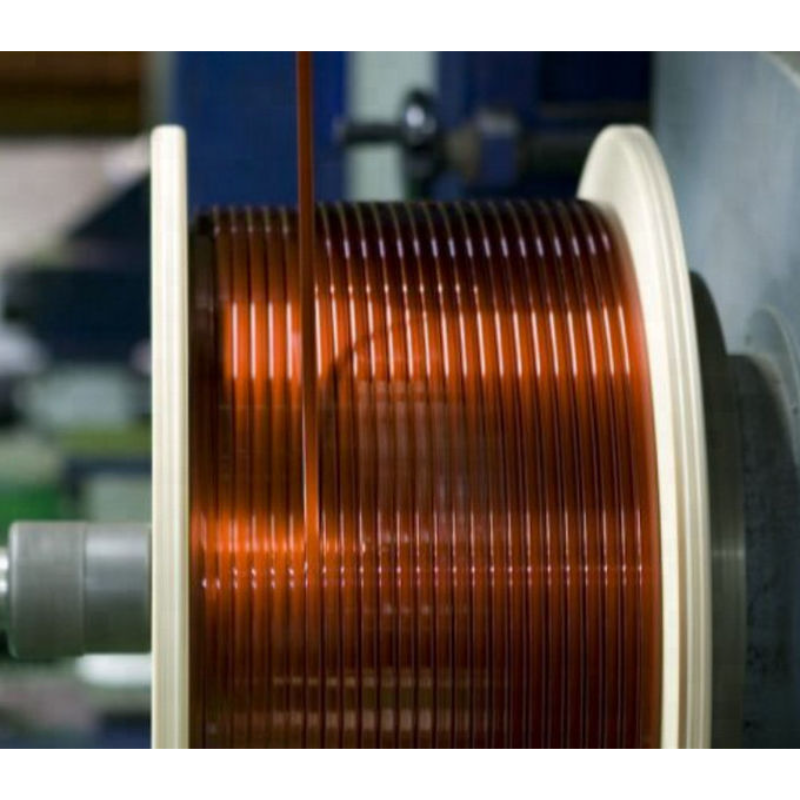

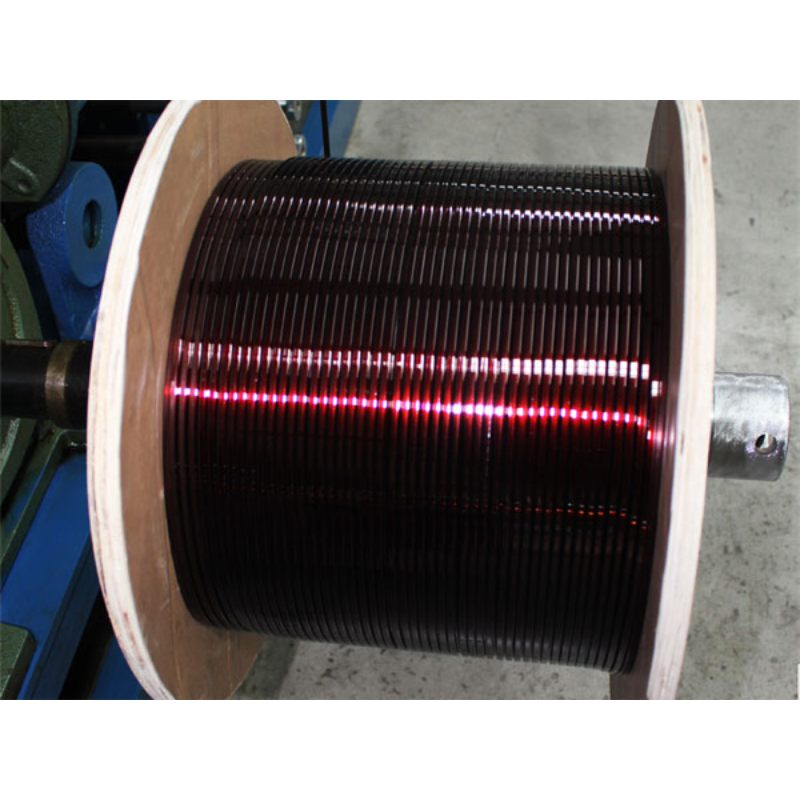

Enameled wire refers to a metal wire that uses insulating varnish as an insulating coating and is used to wind an electromagnetic coil, also known as an electromagnetic wire. It is a main variety of winding wire. It consists of conductor and insulating layer. After the bare wire is softened by annealing, it is painted and baked many times. In most cases, enameled wire is wound into coils of different shapes to provide electromagnetic fields for motors, transformers, electromagnets and other products.

High Speed Super Fine Copper Wire Enameling Machine

1.Power supply:380V×50HZ×3phase

2.The range of diameter:Φ0.05mm–Φ0.12mm

3.The range of wire speeds:400m/min

4.Number of wires produced:24line×max8dies,total 192+18 Dies

5.The coats of painting:monolayer 8 dies, complex 7+1dies

6.Wire pitch:6mm, wire length:1000 mm

7.Leading method:cincture the wire fixed,right and left control 12pieces of metal bond independently .

8.Take-up weight:4-10kg(PT-4、PT-10)

9.Total electric capacity:About 90KW.

10.Coating Color:vacuum furnace and ovens are painted creamy-white lacquer ,the machine body is green ,the taking up wire machine head is green ,the turning tray is black green