Table of Contents

Comparison of Different Rod Breakdown Wire Drawing Copper Wire Drawing Machines

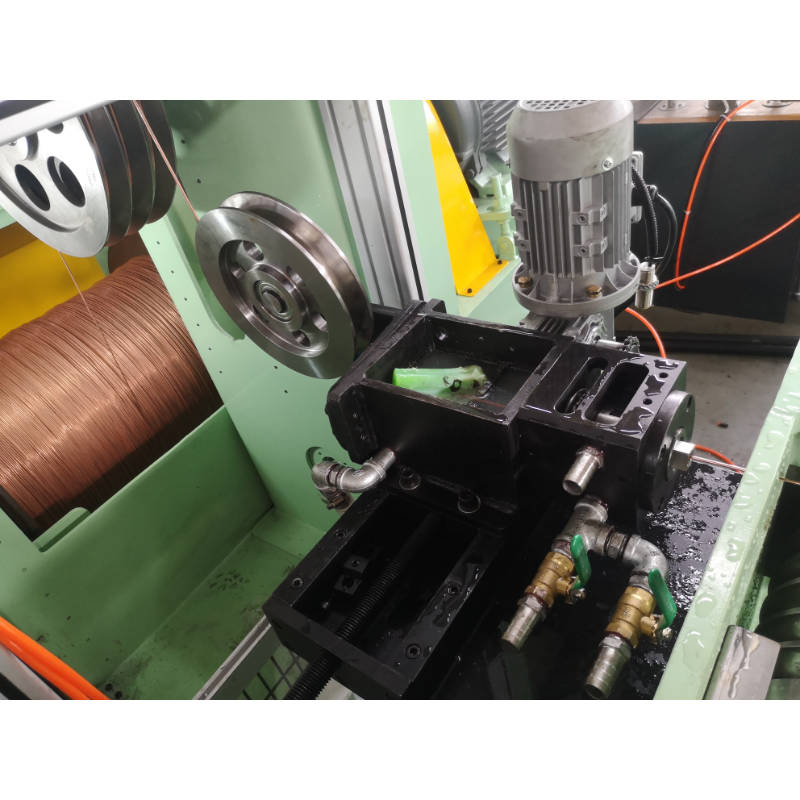

Rod breakdown wire drawing is a crucial process in the production of copper wire. This process involves pulling a rod of copper through a series of dies to reduce its diameter and increase its length. The quality of the wire produced in this process is highly dependent on the type of wire drawing machine used. There are several different types of rod breakdown wire drawing copper wire drawing machines available on the market, each with its own unique features and capabilities.

One of the most common types of rod breakdown wire drawing machines is the single-step machine. This type of machine is simple in design and operation, making it ideal for small-scale production. The single-step machine consists of a series of dies through which the copper rod is pulled in a single continuous process. While this type of machine is cost-effective and easy to operate, it may not be suitable for high-volume production due to its limited speed and capacity.

Another type of rod breakdown wire drawing machine is the multi-step machine. This machine is designed to handle larger volumes of copper rod and produce wire of higher quality. The multi-step machine consists of multiple stages, each with its own set of dies. The copper rod is pulled through each stage in a series of steps, gradually reducing its diameter and increasing its length. This results in a smoother and more uniform wire with fewer imperfections. While the multi-step machine is more complex and expensive than the single-step machine, it is capable of producing higher-quality wire at a faster rate.

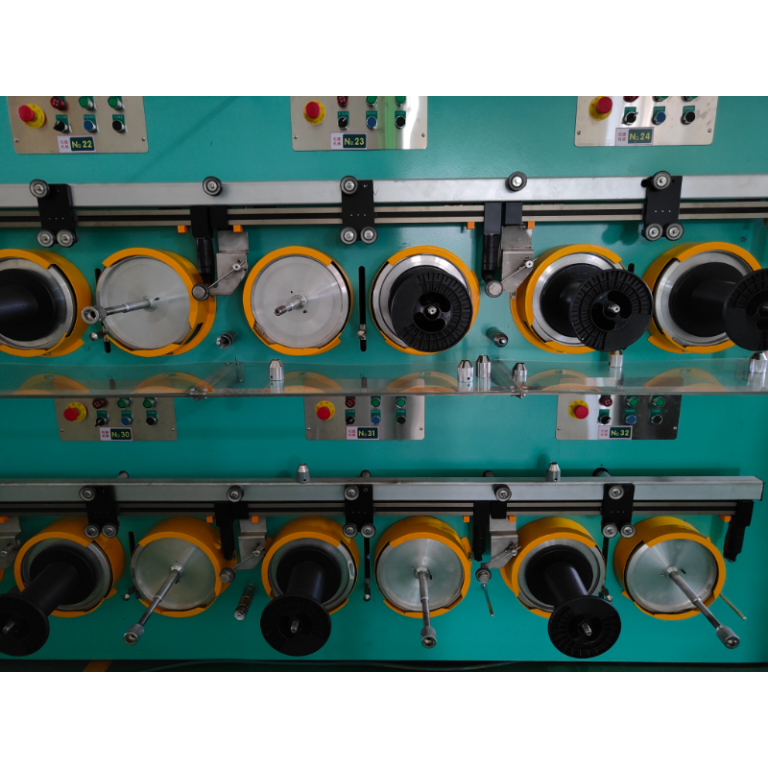

In addition to the single-step and multi-step machines, there are also continuous wire drawing machines available for rod breakdown wire drawing. These machines are designed for continuous operation, allowing for the production of large quantities of wire with minimal downtime. Continuous wire drawing machines are often used in industrial settings where high-volume production is required. These machines are highly efficient and can produce wire of consistent quality at a rapid pace.

When comparing different rod breakdown wire drawing copper wire drawing machines, it is important to consider factors such as speed, capacity, and quality of the wire produced. Single-step machines are suitable for small-scale production and are cost-effective, but may not be suitable for high-volume production. Multi-step machines are capable of producing higher-quality wire at a faster rate, making them ideal for larger-scale operations. Continuous wire drawing machines are designed for continuous operation and are highly efficient, making them ideal for industrial settings.

In conclusion, the choice of Copper Wire Drawing Machine for Rod Breakdown Machine will depend on the specific needs and requirements of the production process. Single-step machines are simple and cost-effective, while multi-step machines offer higher quality and faster production rates. Continuous wire drawing machines are designed for high-volume production and continuous operation. By carefully considering the features and capabilities of each type of machine, manufacturers can select the most suitable machine for their production needs.

Benefits of Using Rod Breakdown Wire Drawing Copper Wire Drawing Machine

Rod breakdown wire drawing copper wire drawing machines are essential tools in the manufacturing industry for producing high-quality copper wire. These machines are designed to efficiently draw copper rods through a series of dies to reduce their diameter and improve their mechanical properties. There are several benefits to using rod breakdown wire drawing copper wire drawing machines, including increased productivity, improved wire quality, and cost savings.

One of the primary benefits of using a rod breakdown wire drawing copper wire drawing machine is increased productivity. These machines are capable of drawing copper rods at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help companies meet tight production deadlines and fulfill customer orders quickly and efficiently. Additionally, the automated nature of these machines reduces the need for manual labor, further increasing productivity and reducing the risk of human error.

Another benefit of using rod breakdown wire drawing copper wire drawing machines is improved wire quality. As copper rods are drawn through the dies, they undergo a process of cold working that improves their mechanical properties, such as strength and ductility. This results in a higher-quality wire that is more durable and reliable for use in various applications. Additionally, the precise control offered by these machines ensures consistent wire diameter and surface finish, further enhancing the overall quality of the product.

Cost savings are also a significant benefit of using rod breakdown wire drawing copper wire drawing machines. By increasing productivity and improving wire quality, manufacturers can reduce production costs and waste. The high efficiency of these machines means less energy and raw materials are required to produce the same amount of wire compared to traditional methods. Additionally, the automated operation of these machines reduces the need for manual labor, saving on labor costs and minimizing the risk of injuries in the workplace.

In addition to these benefits, rod breakdown wire drawing copper wire drawing machines offer versatility and flexibility in wire production. These machines can accommodate a wide range of wire diameters and materials, allowing manufacturers to produce different types of wire for various applications. Whether it’s for electrical wiring, telecommunications, or construction, these machines can be customized to meet specific production requirements and standards.

Overall, rod breakdown wire drawing copper wire drawing machines are essential tools for manufacturers looking to improve productivity, quality, and cost efficiency in their wire production processes. By investing in these machines, companies can streamline their operations, increase output, and deliver high-quality wire products to their customers. With the versatility and flexibility offered by these machines, manufacturers can stay competitive in the market and meet the growing demand for copper wire in various industries.

Tips for Maintaining Rod Breakdown Wire Drawing Copper Wire Drawing Machine

Rod breakdown wire drawing Copper Fine Wire Drawing Machine With Annealer are essential equipment in the wire manufacturing industry. These machines are used to draw copper rods into thinner wires of various diameters. To ensure the smooth operation and longevity of these machines, proper maintenance is crucial. In this article, we will discuss some tips for maintaining rod breakdown wire drawing copper wire drawing machines.

First and foremost, regular cleaning of the machine is essential. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. This can result in decreased efficiency and potential damage to the machine. Cleaning the machine regularly with a soft brush or cloth can help prevent these issues.

In addition to cleaning, lubrication is another important aspect of machine maintenance. Proper lubrication of the machine’s moving parts can help reduce friction and wear, prolonging the machine’s lifespan. It is important to use the correct type of lubricant for each component and to follow the manufacturer’s recommendations for lubrication intervals.

Inspecting the machine for any signs of wear or damage is also crucial. Regular inspections can help identify potential issues before they escalate into major problems. Look for worn or damaged parts, loose bolts or screws, and any unusual noises or vibrations during operation. Addressing these issues promptly can prevent further damage and downtime.

Another important maintenance tip is to calibrate the machine regularly. Over time, the machine’s settings may drift, affecting the quality of the drawn wire. Calibrating the machine ensures that it is operating at optimal performance and producing wires of the desired diameter and quality. Follow the manufacturer’s guidelines for calibration procedures and intervals.

Proper tension control is essential for achieving consistent wire drawing results. Tension control systems should be checked regularly to ensure they are functioning correctly. Adjust the tension settings as needed to maintain the desired wire quality and diameter. Improper tension control can lead to wire breakage, uneven drawing, and other issues.

Regularly monitoring the machine’s performance is also important for maintenance. Keep track of key performance indicators such as wire diameter, speed, and production output. Any deviations from the norm could indicate a problem that needs to be addressed. By monitoring the machine’s performance, you can identify issues early and take corrective action before they escalate.

Lastly, training your operators on proper machine operation and maintenance is crucial. Ensure that your operators are familiar with the machine’s operation manual and safety guidelines. Provide training on how to perform routine maintenance tasks and how to identify and address common issues. Well-trained operators can help prevent accidents, downtime, and costly repairs.

In conclusion, maintaining rod breakdown wire drawing copper wire drawing machines is essential for ensuring their longevity and optimal performance. By following these tips for maintenance, you can prolong the life of your machine, reduce downtime, and produce high-quality wires consistently. Regular cleaning, lubrication, inspection, calibration, tension control, performance monitoring, and operator training are key aspects of machine maintenance. By investing time and effort in maintaining your machines, you can maximize their efficiency and productivity in the long run.