Table of Contents

Tips for Maintaining and Troubleshooting a Vertical Enameling Machine for Aluminum Wire

A Vertical Enameling Machine is a crucial piece of equipment in the wire manufacturing industry. It is used to apply a thin layer of enamel coating to aluminum wire, which helps to protect the wire from corrosion and improve its electrical conductivity. Proper maintenance and troubleshooting of a vertical enameling machine are essential to ensure its smooth operation and prevent costly downtime.

One of the most important tips for maintaining a vertical enameling machine is to regularly clean and lubricate the machine. Over time, dirt, dust, and debris can build up on the machine’s components, causing them to wear out faster and potentially leading to malfunctions. By cleaning the machine regularly and applying lubricant to moving parts, you can help to extend the machine’s lifespan and keep it running smoothly.

Another important maintenance tip is to regularly inspect the machine for any signs of wear or damage. Check for loose or worn-out parts, frayed wires, and any other issues that could affect the machine’s performance. By catching and addressing these issues early on, you can prevent more serious problems from occurring and keep the machine in good working condition.

In addition to regular maintenance, it is also important to troubleshoot any issues that may arise with the vertical enameling machine. One common issue that can occur is uneven coating on the wire. This can be caused by a variety of factors, such as improper tension settings, worn-out dies, or a dirty coating chamber. By identifying the root cause of the issue and making the necessary adjustments, you can ensure that the machine produces consistently high-quality coated wire.

Another common issue that can occur with a vertical enameling machine is overheating. This can be caused by a variety of factors, such as a clogged cooling system, a malfunctioning heating element, or improper ventilation. If you notice that the machine is overheating, it is important to shut it down immediately and investigate the cause of the issue. By addressing the problem promptly, you can prevent damage to the machine and ensure that it continues to operate safely.

In conclusion, proper maintenance and troubleshooting of a vertical enameling machine are essential for ensuring its smooth operation and preventing costly downtime. By following these tips and staying vigilant for any signs of wear or damage, you can keep your machine in good working condition and maximize its lifespan. Remember to clean and lubricate the machine regularly, inspect it for any issues, and troubleshoot any problems that may arise promptly. By taking these steps, you can ensure that your vertical enameling machine continues to produce high-quality coated wire for years to come.

Benefits of Using a Vertical Enameling Machine for Aluminum Wire

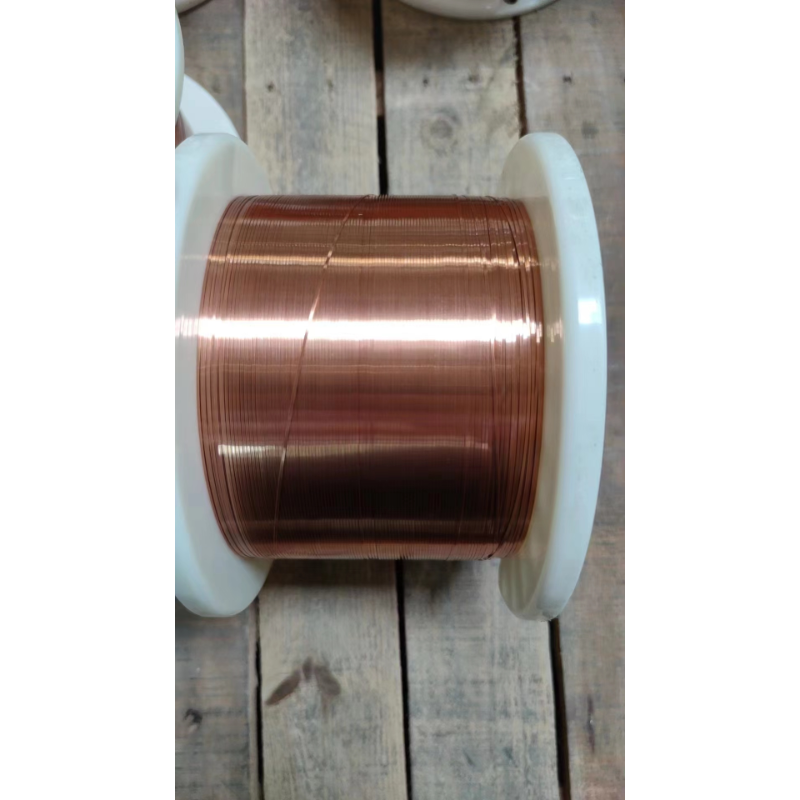

Enameling is a process that involves coating a material with a thin layer of enamel to improve its appearance and durability. When it comes to aluminum wire, enameling is essential to protect the wire from corrosion and improve its electrical conductivity. One of the most efficient ways to enamel aluminum wire is by using a vertical enameling machine.

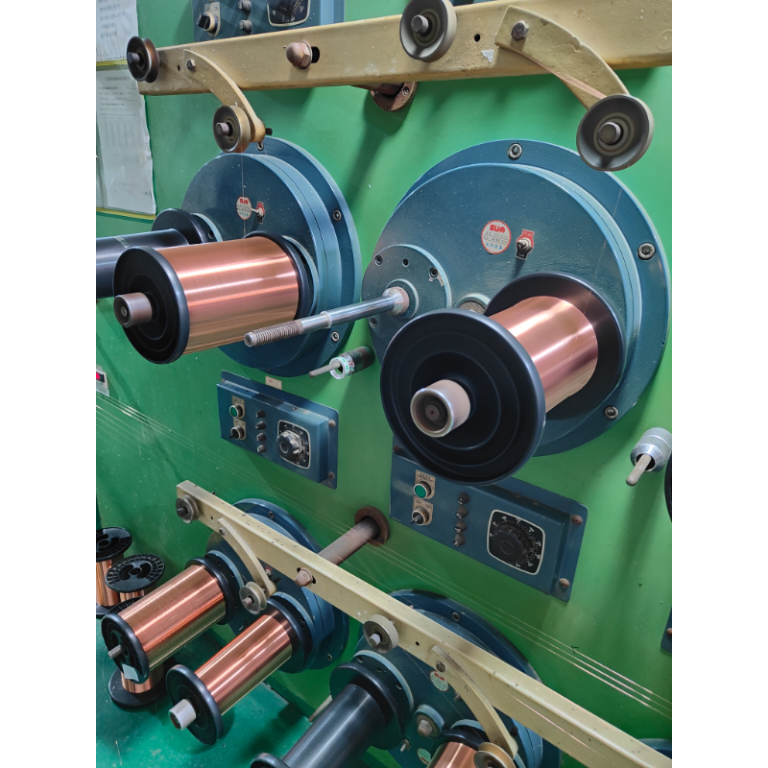

Vertical enameling machines are specifically designed to enamel wire in a vertical orientation, allowing for a more efficient and uniform coating. These machines are equipped with a series of rollers and guides that ensure the wire is properly coated with enamel as it passes through the machine. The vertical orientation of the machine also allows for better control over the enameling process, resulting in a higher quality finish.

One of the key benefits of using a vertical enameling machine for aluminum wire is the ability to enamel wire of various sizes and shapes. These machines are highly versatile and can accommodate a wide range of wire diameters, making them suitable for a variety of applications. Whether you are enameling thin gauge wire for electronics or thicker wire for industrial applications, a vertical enameling machine can meet your needs.

In addition to their versatility, vertical enameling machines are also highly efficient. These machines are designed to enamel wire at high speeds, allowing for increased productivity and reduced production times. This is especially important for manufacturers who need to enamel large quantities of wire on a regular basis. By using a vertical enameling machine, manufacturers can streamline their production process and meet tight deadlines more effectively.

Another benefit of using a vertical enameling machine for aluminum wire is the improved quality of the enamel coating. The vertical orientation of the machine ensures that the enamel is applied evenly and consistently across the entire length of the wire. This results in a more uniform coating that is free from defects such as bubbles or streaks. As a result, the finished wire is more durable and has a higher level of electrical conductivity.

Furthermore, vertical enameling machines are easy to operate and maintain. These machines are equipped with user-friendly controls that allow operators to adjust the speed and tension of the wire with ease. Additionally, the rollers and guides in the machine are designed to be easily accessible for cleaning and maintenance, ensuring that the machine remains in optimal working condition.

Overall, using a vertical enameling machine for aluminum wire offers numerous benefits, including versatility, efficiency, quality, and ease of operation. Whether you are a small-scale manufacturer or a large industrial company, investing in a vertical enameling machine can help improve your production process and enhance the quality of your finished products. With their advanced technology and user-friendly design, vertical enameling machines are a valuable asset for any company looking to enamel aluminum wire efficiently and effectively.