Table of Contents

Step-by-Step Guide to Enameling Process Through Vertical

Enameling is a centuries-old technique that involves fusing powdered glass to metal to create a durable and colorful surface. There are several methods for applying enamel, one of which is the vertical enameling process. This technique involves suspending the metal object vertically and applying the enamel in layers, allowing gravity to help distribute the material evenly.

The first step in the vertical enameling process is to prepare the metal surface. This involves cleaning the metal thoroughly to remove any dirt, grease, or oxidation that could interfere with the adhesion of the enamel. The metal is then coated with a layer of flux, a clear enamel that helps the colored enamel adhere to the metal.

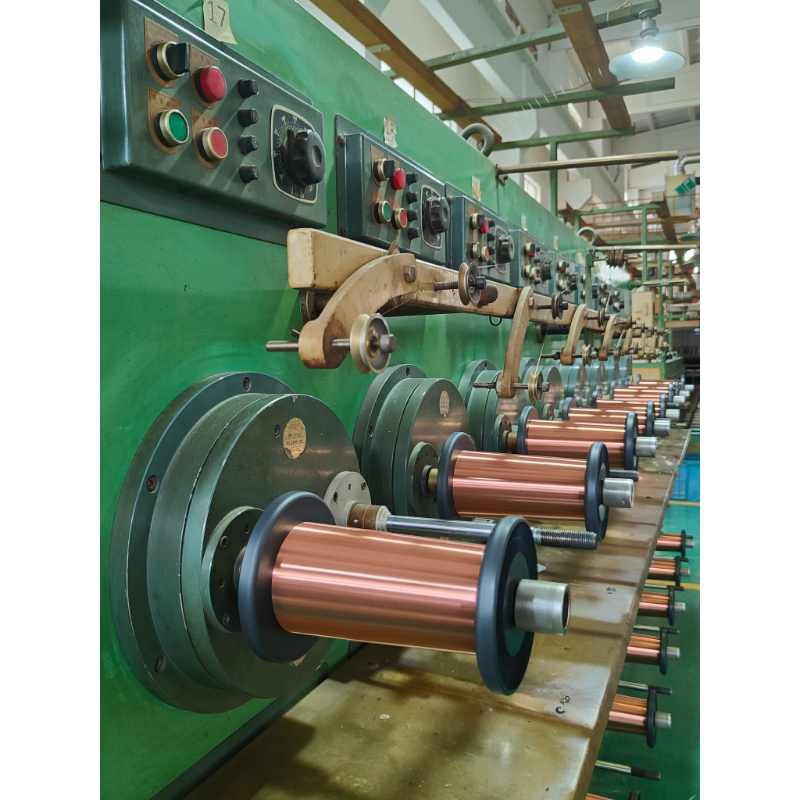

Once the metal is prepared, the next step is to apply the colored enamel. The Enameling Wire Production Line is typically applied in layers, with each layer fired in a kiln at high temperatures to fuse it to the metal. The vertical orientation of the metal allows gravity to help distribute the enamel evenly, resulting in a smooth and uniform surface.

After each layer of enamel is fired, the metal is removed from the kiln and allowed to cool before the next layer is applied. This process is repeated until the desired thickness and color intensity are achieved. The number of layers required will depend on the type of enamel being used and the desired effect.

Once the final layer of enamel has been applied and fired, the metal object is allowed to cool before being polished to a high shine. The vertical enameling process results in a durable and vibrant surface that is resistant to scratching and fading.

One of the advantages of the vertical enameling process is that it allows for greater control over the distribution of the enamel. By suspending the metal object vertically, the enamel can flow naturally down the surface, creating a smooth and even finish. This technique is particularly well-suited for objects with intricate designs or curved surfaces, as the enamel can flow into all the nooks and crannies of the metal.

Another advantage of the vertical enameling process is that it allows for the creation of unique effects and textures. By varying the thickness of the enamel layers or using different colors, artists can create a wide range of effects, from subtle gradients to bold contrasts. The vertical orientation of the metal also allows for the creation of interesting patterns and designs as the enamel flows down the surface.

In conclusion, the vertical enameling process is a versatile and effective technique for creating colorful and durable enamel surfaces. By suspending the metal object vertically and applying the enamel in layers, artists can achieve a smooth and even finish with greater control over the distribution of the enamel. This technique allows for the creation of unique effects and textures, making it a popular choice for artists and craftsmen alike.

Advantages of Enameling Process Through Vertical

Enameling is a process that has been used for centuries to add color and durability to various objects, from jewelry to cookware. One method of enameling that has gained popularity in recent years is the vertical enameling process. This technique involves applying enamel to a vertical surface, such as a wall or a panel, rather than a horizontal surface like a table or a plate.

One of the main advantages of the Vertical Enameling Machine is the ability to create large, seamless designs. When enamel is applied to a vertical surface, it can flow and blend together more easily, resulting in a smooth and uniform finish. This makes it ideal for creating intricate patterns or detailed images that would be difficult to achieve with traditional horizontal enameling techniques.

Another benefit of the vertical enameling process is the ability to work on larger pieces. Because the enamel is applied to a vertical surface, there is no limit to the size of the object that can be enameled. This makes it possible to create large-scale artworks or installations that would be impossible to achieve with traditional horizontal enameling methods.

Additionally, the vertical enameling process allows for greater control over the application of the enamel. By working on a vertical surface, artists can more easily manipulate the flow of the enamel and create precise lines and shapes. This level of control is especially important when working on detailed or intricate designs, as even the smallest mistake can ruin the entire piece.

Furthermore, the vertical enameling process is more efficient than traditional horizontal enameling techniques. Because the enamel is applied to a vertical surface, it can be fired more quickly and evenly, resulting in a faster overall production time. This makes it possible to create multiple pieces in a shorter amount of time, making the vertical enameling process ideal for artists or manufacturers who need to produce large quantities of enameled objects.

In addition to its practical advantages, the vertical enameling process also offers unique creative possibilities. By working on a vertical surface, artists can experiment with different techniques and effects that would be difficult to achieve with traditional horizontal enameling methods. This can result in truly innovative and original artworks that push the boundaries of what is possible with enamel.

Overall, the vertical enameling process offers a number of advantages over traditional horizontal enameling techniques. From the ability to create large, seamless designs to greater control over the application of the enamel, this technique is ideal for artists and manufacturers looking to push the boundaries of what is possible with enamel. Whether you are a seasoned enamel artist or just starting out, the vertical enameling process is definitely worth exploring for its unique creative possibilities and practical advantages.

Common Mistakes to Avoid in Enameling Process Through Vertical

Enameling is a centuries-old technique that involves fusing powdered glass to metal to create a durable and colorful surface. One popular method of enameling is the vertical process, where the enamel is applied to a vertical surface and then fired in a kiln. While this technique can produce stunning results, there are some common mistakes that beginners often make when enameling through vertical.

One of the most common mistakes in the Wire Enameling Plant is not properly cleaning the metal surface before applying the enamel. Any dirt, grease, or oxidation on the metal can prevent the enamel from adhering properly, leading to a patchy or uneven finish. To avoid this mistake, be sure to thoroughly clean the metal with a degreasing agent and a fine abrasive before applying the enamel.

Another common mistake is applying too thick of a layer of enamel. While it may be tempting to pile on the enamel for a more vibrant color, thick layers can lead to cracking and chipping during firing. It is important to apply thin, even layers of enamel to ensure a smooth and durable finish. If you find that your enamel is too thick, you can gently scrape away excess enamel with a sharp tool before firing.

Firing the enamel at the wrong temperature or for the wrong amount of time is another common mistake in the vertical enameling process. Different types of enamel require different firing temperatures and times, so it is important to follow the manufacturer’s instructions carefully. Firing too hot or for too long can cause the enamel to bubble, blister, or even burn off the metal surface. To avoid this mistake, invest in a good quality kiln with accurate temperature controls and use a timer to ensure that you fire your enamel for the correct amount of time.

Not properly annealing the enamel after firing is another common mistake that can lead to a brittle and easily damaged finish. Annealing is the process of slowly cooling the enamel to room temperature to relieve internal stresses and prevent cracking. To properly anneal your enamel, allow it to cool in the kiln for a few minutes before removing it and placing it in a bed of vermiculite or other insulating material to cool slowly. This will help ensure that your enamel is strong and durable.

Finally, one of the most common mistakes in the vertical enameling process is not practicing proper safety precautions. Enameling involves working with high temperatures and toxic materials, so it is important to wear protective gear such as gloves, goggles, and a respirator to protect yourself from burns and fumes. It is also important to work in a well-ventilated area and to follow proper safety procedures when handling and disposing of enamel materials.

In conclusion, the vertical enameling process can produce beautiful and durable results, but there are some common mistakes that beginners often make. By properly cleaning the metal surface, applying thin layers of enamel, firing at the correct temperature and time, annealing the enamel after firing, and practicing proper safety precautions, you can avoid these common mistakes and create stunning enameled pieces that will last for years to come.