Benefits of Using High Speed Super Fine Copper Wire Enameling Machine

In the world of manufacturing, efficiency and precision are key factors in ensuring high-quality products. One crucial aspect of the manufacturing process is the enameling of copper wire, which is used in a wide range of industries such as electronics, telecommunications, and automotive. To meet the demands of modern production, manufacturers are turning to high-speed super fine copper wire enameling machines.

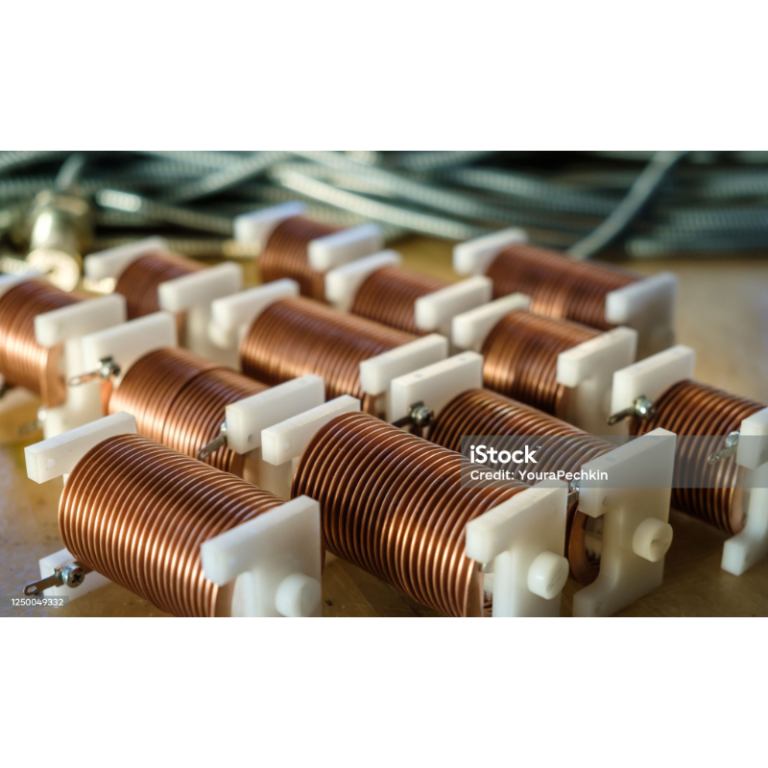

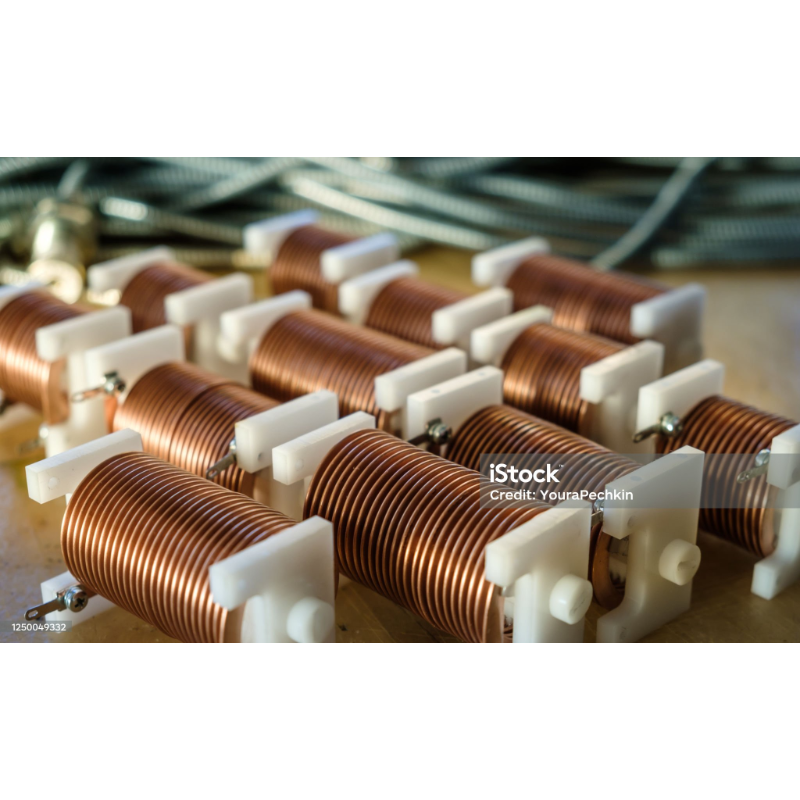

These machines are designed to coat copper wire with a thin layer of enamel, which serves as insulation and protection. The high-speed capabilities of these machines allow for faster production rates, resulting in increased output and reduced lead times. This is especially beneficial for manufacturers who need to meet tight deadlines and high production volumes.

One of the main benefits of using a high-speed super fine copper Wire Enameling Plant is the superior quality of the enamel coating. The high-speed process ensures that the enamel is applied evenly and consistently, resulting in a smooth and uniform finish. This is essential for ensuring the reliability and performance of the final product, as any inconsistencies in the enamel coating can lead to electrical shorts or other issues.

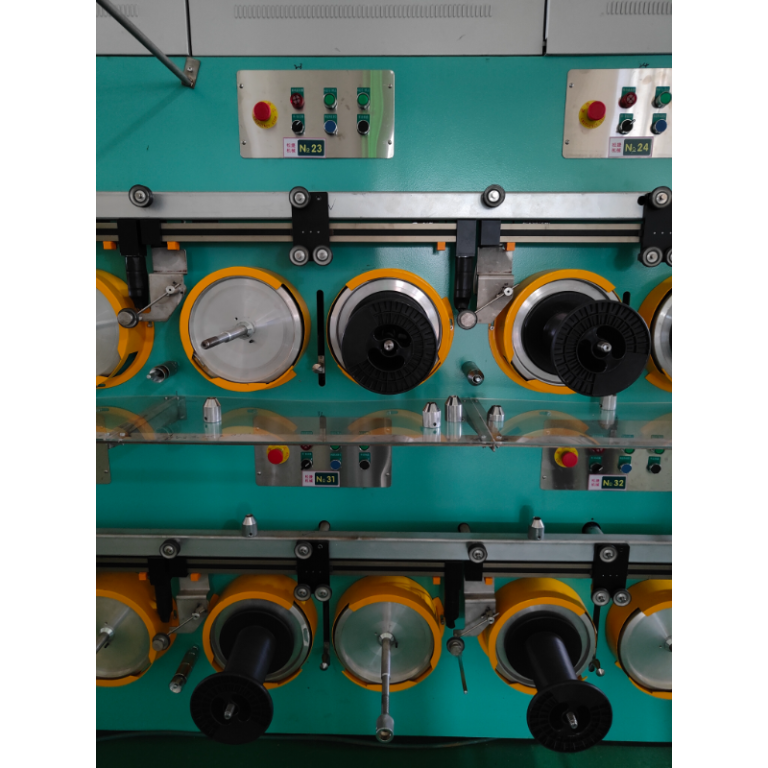

Another advantage of these machines is their versatility. They can handle a wide range of wire sizes and types, making them suitable for a variety of applications. Whether you need to enamel thin gauge wire for electronics or thicker wire for industrial applications, a high-speed super fine copper wire enameling machine can meet your needs.

In addition to their speed and quality, these machines are also highly efficient. They are designed to minimize waste and reduce downtime, resulting in cost savings for manufacturers. The automated processes of these machines also help to improve worker safety by reducing the need for manual labor and handling of hot enamel.

Furthermore, high-speed super fine copper wire enameling machines are equipped with advanced technology that allows for precise control over the enameling process. This ensures that the enamel coating meets the required specifications and standards, leading to consistent and reliable results. Manufacturers can also easily adjust settings to accommodate different wire sizes or enamel types, making these machines highly adaptable to changing production needs.

Overall, the benefits of using a high-speed super fine copper wire enameling machine are clear. From increased production rates and superior quality to cost savings and efficiency, these machines offer a range of advantages for manufacturers in various industries. By investing in this advanced technology, manufacturers can stay ahead of the competition and meet the demands of today’s fast-paced manufacturing environment.