Table of Contents

Maintenance Tips for Aluminum Wire Drawing Machine

Aluminum wire drawing machines are essential equipment in the manufacturing industry, used to produce aluminum wires of various diameters for a wide range of applications. To ensure the smooth operation and longevity of these machines, regular maintenance is crucial. In this article, we will discuss some maintenance tips for aluminum wire drawing machines to help you keep your equipment in top condition.

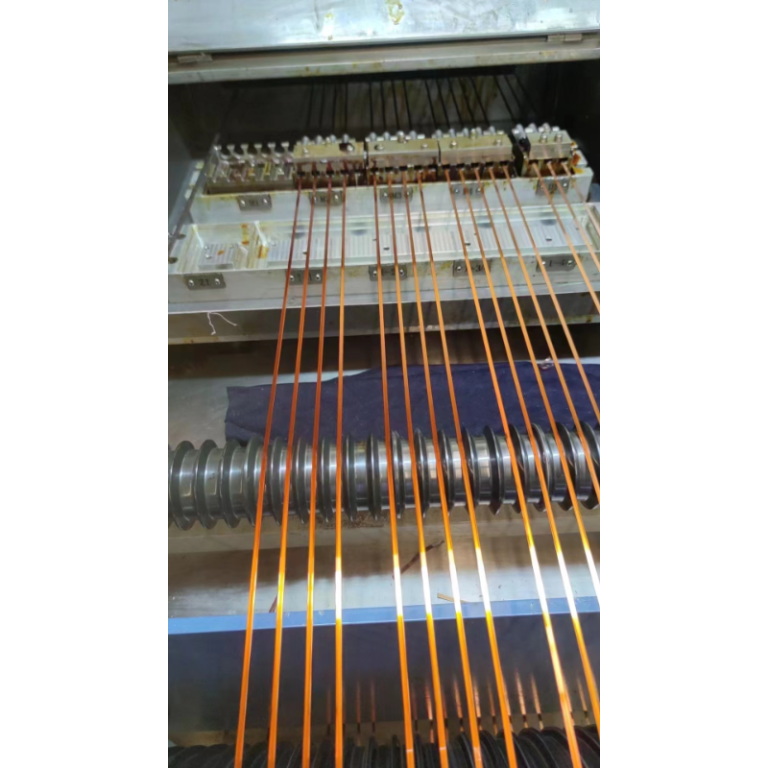

One of the most important maintenance tasks for Aluminum Wire Breakdown Machine is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. This can result in decreased efficiency and potential damage to the machine. To prevent this, it is recommended to clean the machine regularly using a soft brush or cloth to remove any buildup.

In addition to cleaning, lubrication is another key aspect of maintenance for aluminum wire drawing machines. Proper lubrication helps reduce friction between moving parts, prolonging the life of the machine and ensuring smooth operation. It is important to use the correct type of lubricant recommended by the manufacturer and to apply it to all moving parts regularly.

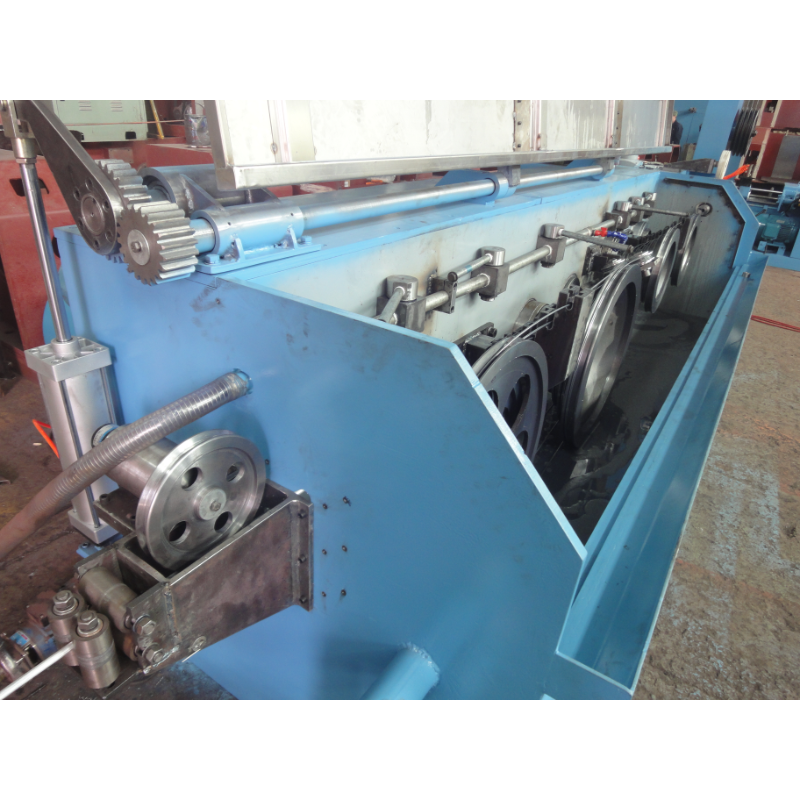

Inspecting the machine for any signs of wear or damage is also essential for maintenance. Check for loose or worn-out parts, such as belts, bearings, and gears, and replace them as needed. Regular inspections can help identify potential issues early on and prevent costly repairs down the line.

Another important maintenance tip for aluminum wire drawing machines is to monitor the machine’s performance regularly. Keep an eye on the wire quality, speed, and tension to ensure that the machine is operating at its optimal level. Any deviations from the norm should be investigated and addressed promptly to prevent further damage to the machine.

It is also important to follow the manufacturer’s recommended maintenance schedule for your aluminum wire drawing machine. This may include tasks such as belt replacement, motor inspection, and calibration of the machine’s settings. By following the recommended maintenance schedule, you can ensure that your machine remains in good working condition and avoid unexpected breakdowns.

Lastly, proper training of operators is crucial for the maintenance of aluminum wire drawing machines. Make sure that your operators are trained in the proper use and maintenance of the equipment to prevent misuse and damage. Regular training sessions can help keep operators up to date on best practices and ensure that the machine is operated safely and efficiently.

In conclusion, regular maintenance is essential for the proper functioning and longevity of aluminum wire drawing machines. By following these maintenance tips, you can keep your equipment in top condition and avoid costly repairs. Remember to clean, lubricate, inspect, monitor, follow the manufacturer’s recommendations, and train your operators to ensure that your aluminum wire drawing machine operates smoothly and efficiently for years to come.

Comparison of Different Types of Aluminum Wire Drawing Machines

Aluminum wire drawing machines are essential tools in the manufacturing industry for producing high-quality aluminum wires of various diameters. These machines are used to reduce the diameter of aluminum rods or wires by pulling them through a series of dies, resulting in a smoother surface finish and improved mechanical properties. There are several types of Aluminum Alloy Wire Drawing Machine available on the market, each with its own unique features and capabilities. In this article, we will compare different types of aluminum wire drawing machines to help you choose the best one for your specific needs.

One of the most common types of aluminum wire drawing machines is the single-step drawing machine. This type of machine consists of a single die through which the aluminum wire is pulled to reduce its diameter in one step. Single-step drawing machines are simple to operate and are suitable for producing wires with a relatively small reduction in diameter. However, they may not be suitable for producing wires with a high reduction ratio or for achieving very fine wire diameters.

In contrast, multi-step drawing machines are designed to reduce the diameter of aluminum wires in multiple steps, using a series of dies with progressively smaller diameters. This allows for a higher reduction ratio and the production of finer wire diameters. Multi-step drawing machines are more versatile and can be used to produce a wide range of wire sizes. However, they are more complex to operate and require more maintenance compared to single-step drawing machines.

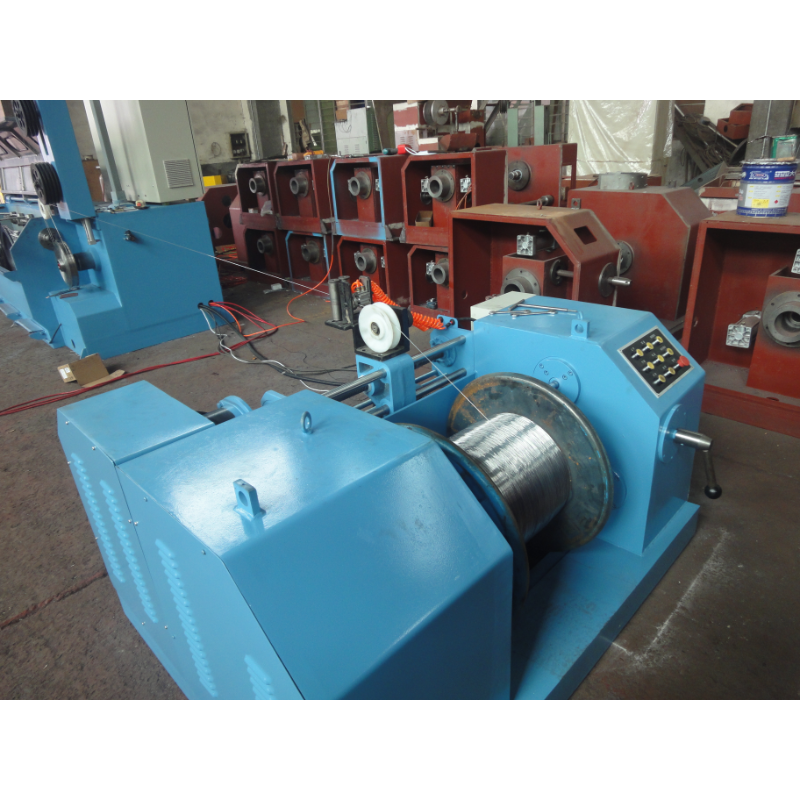

Another type of aluminum wire drawing machine is the continuous drawing machine, which is designed for high-volume production of aluminum wires. Continuous drawing machines are equipped with multiple drawing dies arranged in a straight line, allowing for continuous feeding of aluminum rods or wires into the machine. This results in a continuous output of aluminum wires with consistent diameter and surface finish. Continuous drawing machines are ideal for mass production applications where high productivity is required.

In addition to the above types, there are also specialized aluminum wire drawing machines available for specific applications. For example, wet drawing machines are used for drawing aluminum wires with a lubricant or coolant to improve the drawing process and reduce friction. Dry drawing machines, on the other hand, do not use any lubricant or coolant and are suitable for drawing aluminum wires that do not require additional surface treatment.

When choosing an aluminum wire drawing machine, it is important to consider factors such as the desired wire diameter, reduction ratio, production volume, and level of automation required. It is also important to consider the quality of the machine, including its durability, reliability, and ease of maintenance. Ultimately, the choice of aluminum wire drawing machine will depend on your specific production requirements and budget.

In conclusion, aluminum wire drawing machines play a crucial role in the manufacturing industry for producing high-quality aluminum wires. By comparing different types of aluminum wire drawing machines, you can choose the best machine for your specific needs and achieve optimal results in your production process. Whether you need a single-step drawing machine for small-scale production or a continuous drawing machine for high-volume production, there is a wide range of options available to meet your requirements.

Benefits of Using Aluminum Wire Drawing Machine

Aluminum wire drawing machines are essential tools in the manufacturing industry, particularly in the production of aluminum wires. These machines are designed to reduce the diameter of aluminum rods or wires by pulling them through a series of dies, resulting in a smoother and more uniform wire. There are several benefits to using aluminum wire drawing machines, which make them a valuable investment for companies looking to improve their production processes.

One of the primary benefits of using an aluminum wire drawing machine is the ability to control the diameter and quality of the wire produced. By adjusting the speed and tension of the machine, manufacturers can achieve precise measurements and consistent results, ensuring that the final product meets the required specifications. This level of control is essential for industries that require high-quality aluminum wires for various applications, such as electrical wiring, construction, and automotive manufacturing.

Another advantage of using aluminum wire drawing machines is the ability to increase production efficiency. These machines are capable of processing large volumes of aluminum rods or wires in a relatively short amount of time, allowing manufacturers to meet tight deadlines and fulfill customer orders quickly. Additionally, the smooth and uniform finish of the wire produced by these machines reduces the need for additional processing steps, saving time and resources in the production process.

In addition to improving production efficiency, aluminum wire drawing machines also help reduce material waste. By pulling the aluminum rods or wires through a series of dies, these machines remove surface imperfections and defects, resulting in a higher yield of usable wire. This not only reduces the amount of scrap generated during the manufacturing process but also minimizes the overall cost of production by maximizing the use of raw materials.

Furthermore, aluminum wire drawing machines offer versatility in terms of wire diameter and length. Manufacturers can easily adjust the settings of the machine to produce wires of different sizes and lengths, depending on the requirements of the specific application. This flexibility allows companies to meet the diverse needs of their customers and adapt to changing market demands without the need for additional equipment or resources.

In conclusion, aluminum wire drawing machines offer a range of benefits for manufacturers in the production of aluminum wires. From controlling the diameter and quality of the wire to increasing production efficiency and reducing material waste, these machines play a crucial role in improving the overall manufacturing process. With their versatility and precision, aluminum wire drawing machines are a valuable investment for companies looking to enhance their production capabilities and meet the demands of a competitive market.