Table of Contents

Tips for Maintaining and Troubleshooting Aluminum Wire Drawing Machine

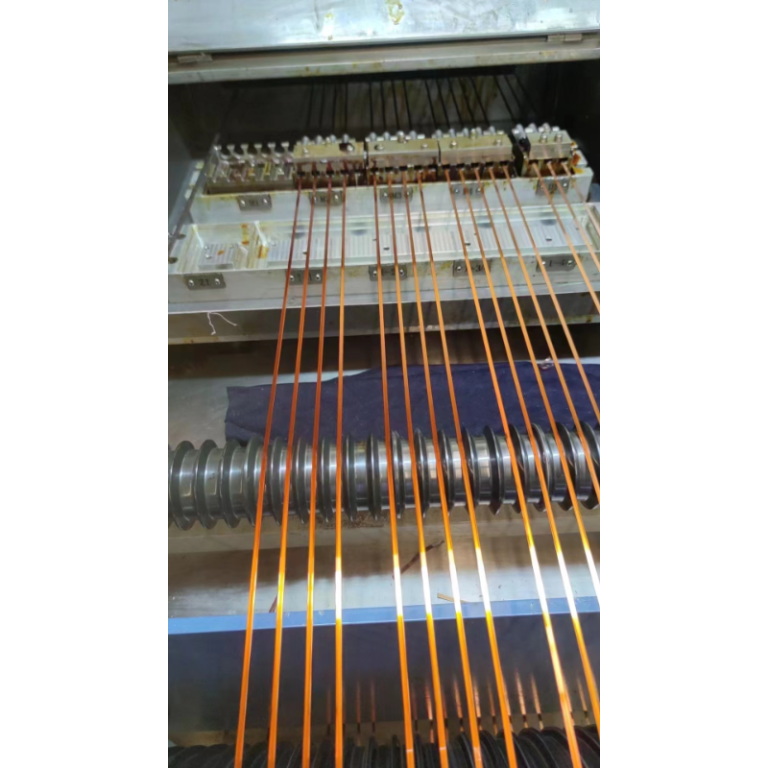

Aluminum wire drawing machines are essential equipment in the wire cable making industry. These machines are used to reduce the diameter of aluminum wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. Proper maintenance and troubleshooting of the aluminum wire drawing machine are crucial to ensure its optimal performance and longevity.

Regular maintenance of the aluminum wire drawing machine is key to preventing breakdowns and ensuring smooth operation. One important aspect of maintenance is keeping the machine clean and free of debris. Dust, dirt, and other contaminants can build up on the machine’s components, leading to increased friction and wear. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues.

In addition to keeping the machine clean, it is important to regularly inspect and lubricate its moving parts. Over time, the components of the machine can wear down and become less efficient. By inspecting and lubricating these parts regularly, you can prevent premature wear and extend the life of the machine.

Another important aspect of maintaining an Aluminum Sheet Wire Drawing Machine is monitoring its electrical components. Electrical issues can cause the machine to malfunction or stop working altogether. Regularly checking the machine’s wiring, connections, and electrical components can help prevent these issues. If you notice any loose connections or frayed wires, it is important to address them immediately to prevent further damage.

Despite regular maintenance, aluminum wire drawing machines may still experience issues from time to time. When troubleshooting these issues, it is important to approach the problem systematically. Start by identifying the specific issue and then work backwards to determine the root cause.

One common issue with aluminum wire drawing machines is uneven wire diameter. This can be caused by a variety of factors, such as worn dies, improper lubrication, or incorrect machine settings. To troubleshoot this issue, start by checking the condition of the dies and lubricating the machine’s moving parts. If the issue persists, adjust the machine’s settings to ensure a more uniform wire diameter.

Another common issue with aluminum wire drawing machines is overheating. Overheating can be caused by a variety of factors, such as a lack of lubrication, worn components, or excessive friction. To troubleshoot this issue, start by checking the machine’s lubrication and adjusting it as needed. If the issue persists, inspect the machine’s components for signs of wear and replace any worn parts.

In conclusion, proper maintenance and troubleshooting of aluminum wire drawing machines are essential to ensure their optimal performance and longevity. By keeping the machine clean, inspecting and lubricating its moving parts, and monitoring its electrical components, you can prevent breakdowns and ensure smooth operation. When troubleshooting issues with the machine, approach the problem systematically and address the root cause to prevent further damage. By following these tips, you can keep your aluminum wire drawing machine running smoothly for years to come.

Advantages of Using Aluminum Wire Drawing Machine for Wire Cable Making Machine

Aluminum wire drawing machines are essential equipment in the wire cable making industry. These machines are designed to pull aluminum wire through a series of dies to reduce its diameter and improve its quality. There are several advantages to using aluminum wire drawing machines for wire cable making machines.

One of the main advantages of using aluminum wire drawing machines is the ability to produce high-quality wire with consistent diameter and surface finish. The drawing process helps to remove any imperfections in the wire, resulting in a smooth and uniform surface. This is crucial for ensuring the reliability and performance of the wire in various applications.

Another advantage of using aluminum wire drawing machines is the ability to control the mechanical properties of the wire. By adjusting the speed and tension of the drawing process, manufacturers can tailor the strength, ductility, and other properties of the wire to meet specific requirements. This level of customization is essential for producing wires that are suitable for a wide range of applications, from electrical wiring to automotive components.

Aluminum wire drawing machines also offer increased productivity and efficiency in the wire cable making process. These machines are capable of drawing wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This helps to reduce production costs and meet tight deadlines without compromising on quality.

Furthermore, aluminum wire drawing machines are versatile and can be used to draw wires of various diameters and lengths. This flexibility makes them suitable for producing a wide range of wire products, from thin electrical wires to thick cables used in construction and industrial applications. Manufacturers can easily switch between different wire sizes by changing the dies and adjusting the machine settings, making it easy to adapt to changing market demands.

In addition to these advantages, aluminum wire drawing machines are also cost-effective and environmentally friendly. The drawing process helps to reduce material waste by recycling scrap aluminum into high-quality wire. This not only saves on raw material costs but also minimizes the environmental impact of the manufacturing process. Furthermore, the energy-efficient design of these machines helps to reduce electricity consumption, making them a sustainable choice for wire cable making operations.

Overall, aluminum wire drawing machines offer numerous advantages for manufacturers in the wire cable making industry. From producing high-quality wire with consistent properties to increasing productivity and efficiency, these machines play a crucial role in ensuring the success of wire cable manufacturing operations. With their versatility, cost-effectiveness, and environmental benefits, aluminum wire drawing machines are a valuable investment for any wire cable making business looking to stay competitive in the market.