Table of Contents

How to Properly Maintain and Adjust the Tensioning Device on a Cable Wire Drawing Machine

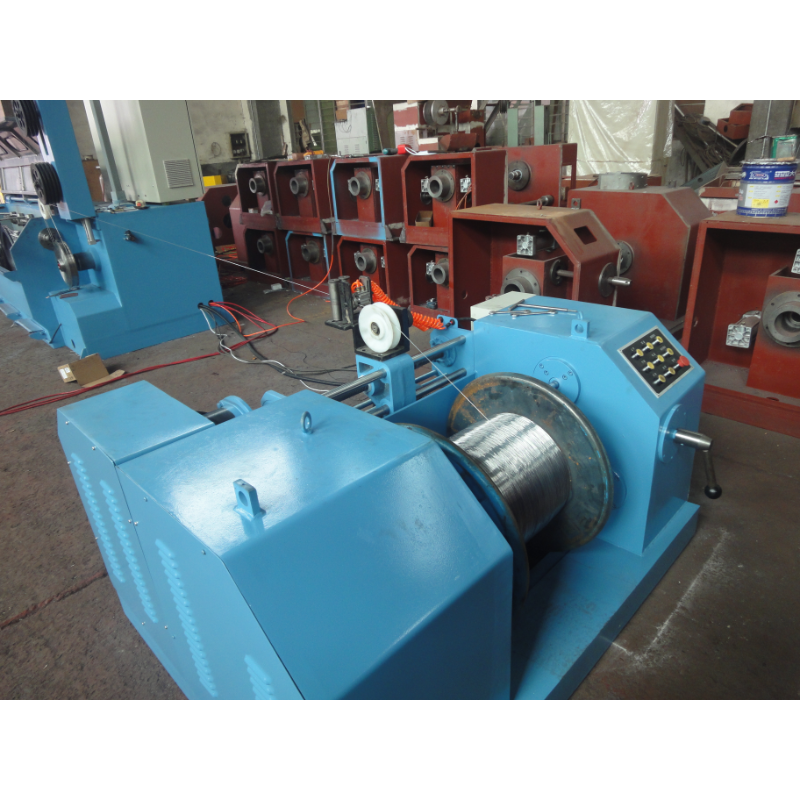

Wire drawing machines are essential tools in the manufacturing of cables, as they are used to pull a metal wire through a series of dies to reduce its diameter and increase its length. One crucial component of a wire drawing machine is the tensioning device, which helps to maintain the proper tension on the wire as it is being drawn. Proper maintenance and adjustment of the tensioning device are essential to ensure the smooth operation of the machine and the production of high-quality cables.

To properly maintain the tensioning device on a Aluminum Wire Drawing Machine, it is important to regularly inspect the device for any signs of wear or damage. This includes checking the tensioning rollers, springs, and other components for any signs of wear, corrosion, or misalignment. Any damaged or worn parts should be replaced immediately to prevent further damage to the machine and ensure the proper tension is maintained on the wire.

In addition to regular inspections, it is also important to lubricate the tensioning device regularly to ensure smooth operation. This includes applying a small amount of lubricant to the tensioning rollers and other moving parts to reduce friction and prevent premature wear. It is important to use the correct type of lubricant for the tensioning device to prevent damage to the machine and ensure proper operation.

When adjusting the tensioning device on a cable wire drawing machine, it is important to follow the manufacturer’s guidelines and recommendations. This includes adjusting the tensioning rollers to the proper position and tension to ensure the wire is drawn smoothly and evenly. It is important to make small adjustments and test the machine after each adjustment to ensure the proper tension is maintained.

It is also important to regularly check the tension on the wire as it is being drawn to ensure it is within the proper range. This can be done by using a tension gauge to measure the tension on the wire and adjusting the tensioning device as needed. It is important to monitor the tension on the wire throughout the drawing process to ensure the proper tension is maintained and prevent any issues with the quality of the cable.

Proper maintenance and adjustment of the tensioning device on a cable wire drawing machine are essential to ensure the smooth operation of the machine and the production of high-quality cables. By regularly inspecting and lubricating the tensioning device, as well as following the manufacturer’s guidelines for adjusting the tension, you can ensure the proper tension is maintained on the wire and prevent any issues with the quality of the cable.

In conclusion, the tensioning device is a crucial component of a cable wire drawing machine, and proper maintenance and adjustment are essential to ensure the smooth operation of the machine and the production of high-quality cables. By regularly inspecting, lubricating, and adjusting the tensioning device, you can ensure the proper tension is maintained on the wire and prevent any issues with the quality of the cable.

Benefits of Using a Tensioning Device in Aluminum Wire Drawing Machines

Aluminum wire drawing machines are essential tools in the cable manufacturing industry, used to reduce the diameter of aluminum wire to the desired size. One crucial component of these machines is the tensioning device, which plays a vital role in ensuring the quality and efficiency of the wire drawing process.

The tensioning device in an aluminum wire drawing machine is responsible for maintaining a consistent tension on the wire as it passes through the drawing dies. This is crucial for achieving uniform wire diameter and preventing breakage or deformation of the wire during the drawing process. By applying the right amount of tension, the tensioning device helps to control the speed at which the wire is drawn, ensuring a smooth and efficient operation.

One of the key benefits of using a tensioning device in an Aluminum Wire Intermediate Drawing Machine is improved product quality. By maintaining a consistent tension on the wire, the tensioning device helps to produce wire with uniform diameter and surface finish. This is essential for ensuring the quality and performance of the final cable product. Inconsistent tension can lead to variations in wire diameter, which can affect the electrical conductivity and mechanical properties of the cable.

Another benefit of using a tensioning device is increased productivity. By controlling the tension on the wire, the tensioning device allows for higher drawing speeds without compromising the quality of the wire. This results in faster production rates and higher output, leading to increased efficiency and profitability for cable manufacturers. Additionally, the use of a tensioning device can help to reduce downtime and maintenance costs by preventing wire breakage and other issues that can arise from improper tension control.

Furthermore, the tensioning device in an aluminum wire drawing machine helps to extend the life of the drawing dies. By maintaining a consistent tension on the wire, the tensioning device reduces the wear and tear on the drawing dies, prolonging their lifespan and reducing the need for frequent replacements. This not only saves money on die maintenance and replacement costs but also ensures consistent wire quality over time.

In conclusion, the tensioning device is a critical component of an aluminum wire drawing machine that plays a key role in ensuring the quality, efficiency, and productivity of the wire drawing process. By maintaining a consistent tension on the wire, the tensioning device helps to produce wire with uniform diameter and surface finish, leading to improved product quality. Additionally, the use of a tensioning device allows for higher drawing speeds, increased productivity, and extended die life, resulting in cost savings and improved profitability for cable manufacturers. Overall, the benefits of using a tensioning device in an aluminum wire drawing machine are clear, making it an essential tool for cable manufacturers looking to achieve high-quality and efficient wire drawing operations.