Wet Wire Drawing Machine,Copper Wire Drawing Machine,Copper Wire Drawing Machine With Annealer

It is used to drawing and annealing copper rod. In addition, it is applied to making electric wire. Our company will provide a series of production equipment to meet our customers’ need, concluding drawing machine, rigid frame stranding machine and extruder.

Copper Wire Drawing Machine,Copper Wire Drawing Making Machine,Copper Wire Drawing Machine With Annealer

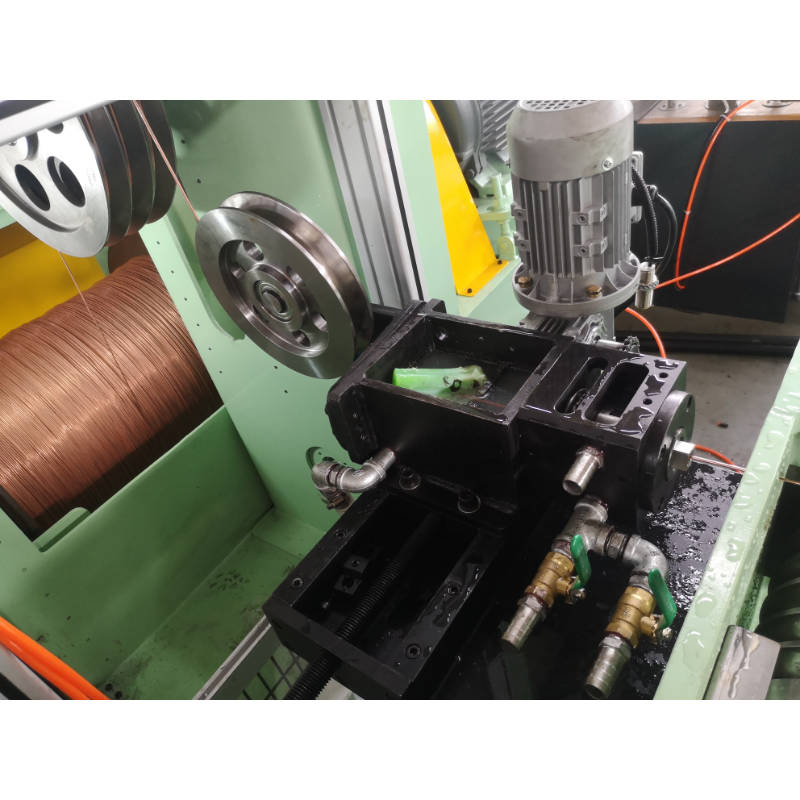

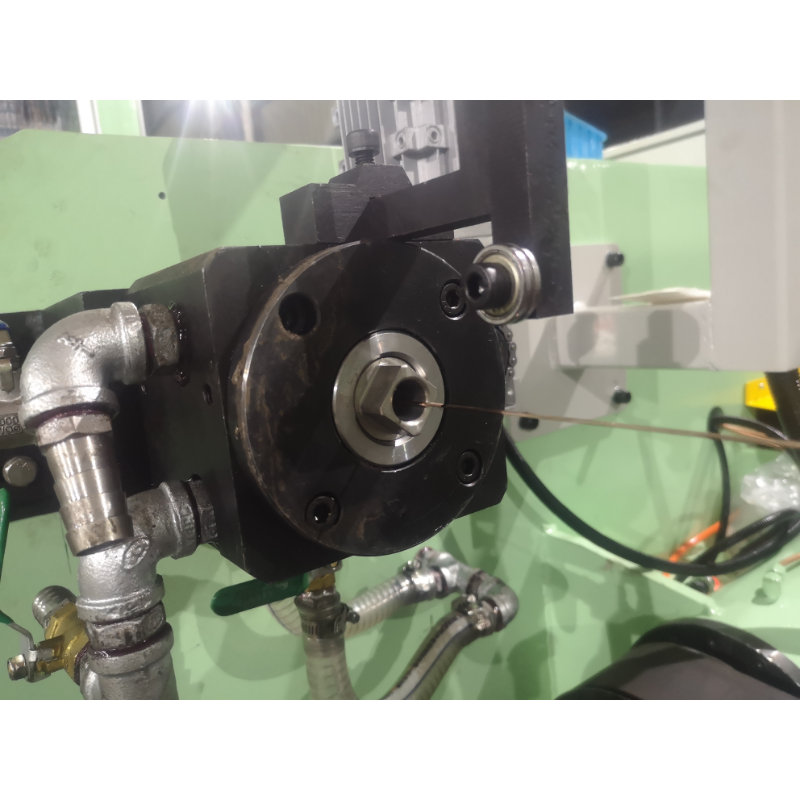

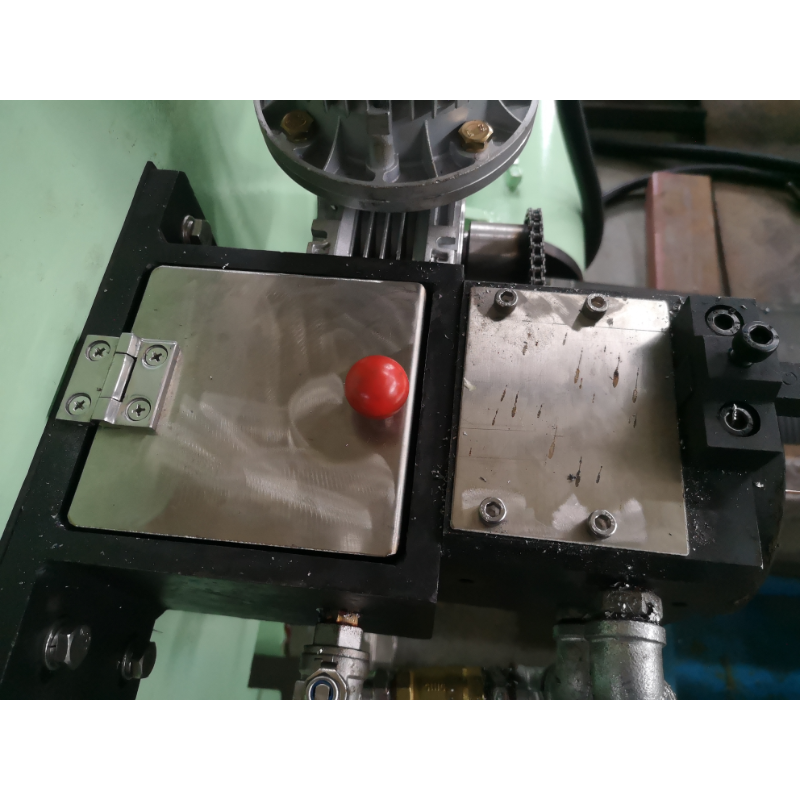

This Copper Wire Drawing Machine is used to draw copper rod inlet diameter of 8mm to copper wire outlet diameter(max.) of 3.2mm. Drawing capstan adopts linear horizontal arrangement, with continuous drawing and continuous annealing. Machine speed matches with the electrical speed, which achieves quick die changing and automatic bobbin shift without pause. This machine takes advantage of easy operation, high production efficiency and high product quality.

Extensively used for providing copper wire to make barbed wire, wire mesh and many more, this technologically advanced Copper Wire Drawing Machine is widely demanded amongst clients for its hassle free operation. This machine is manufactured using supreme grade components with the utilization of ultra-modern technology in tune with defined industry standards. Further, this Ultrafine copper wire drwaing machine is available in numerous technical specifications as per the varied needs of the clients at a competitive price. We are professional copper wire drawing machine manufacturers.

Product parameter:

Machine type:LHT400/13,LHT400/11,LHT400/9,LHT400/8

Power control:Double inverter control

Inlet Dia.:8mm

Outlet Dia:1.2~3.2(mm),1.7~3.2(mm),2.3~3.2(mm),2.6~3.2(mm)

Drawing Drum Dia:400(mm)

Fix speed capstan Dia:400(mm)

Max.Die No.:13,11,9,8

Drawing Speed(Max.):15(m/s),12(m/s),12(m/s),11(m/s)

Main Motor (KW):160(AC/DC),132(AC/DC)

Drum arrangement:Horizontal type

Drawing drum:Coated by tungsten

Drum lubrication type:Immersed type

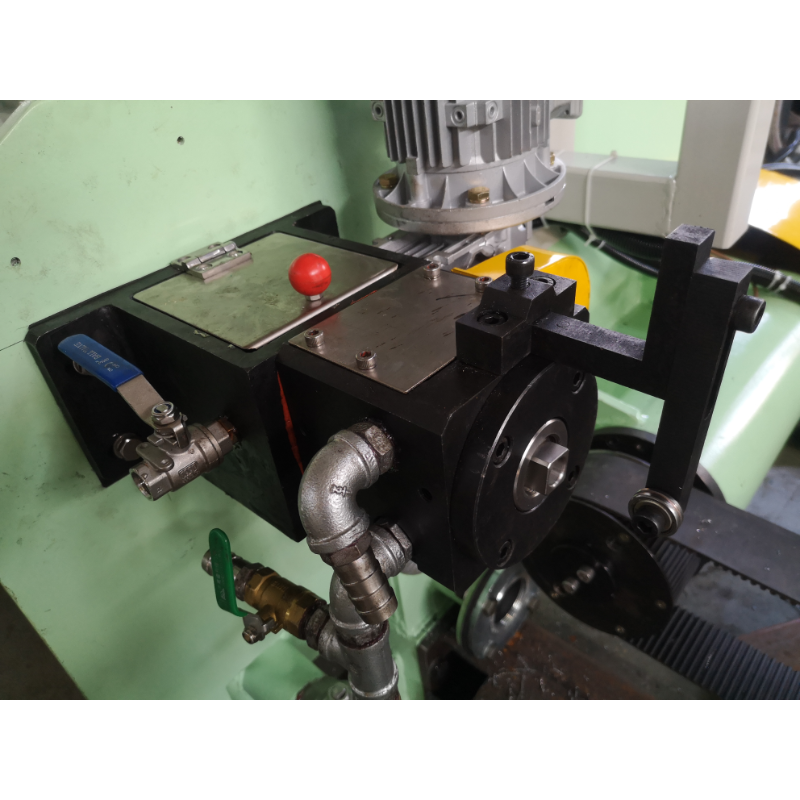

Gear,bearing lubrication:By special pump,spray type

Online Continuous Annealer

Machine structure:Horizontal type

Annealing Wheel Dia:350(mm)

Max annealing voltage(V):65V(DC),60V(DC)

Max annealing current(A):4500,4000

Take-up type(optional):Double Take-up/Single Take-up/Colier

Optional equipment:Horizontal continuous annealer online

Optional function:Fast change die

•Wet type drawing machines are best suited for breaking down copper and aluminium wires, and drawing iron and steel wires.

•Worm gear or spiral bevel gear capstan drive system reduces transmission noise and vibration.

•Take your choice of spooler, non-stop coiler, or bending coiler take-up systems.

•Special model DPR drum-type long pointing unit is avaliable