Maintenance Tips For Standard Rod Breakdown Drawing Machine

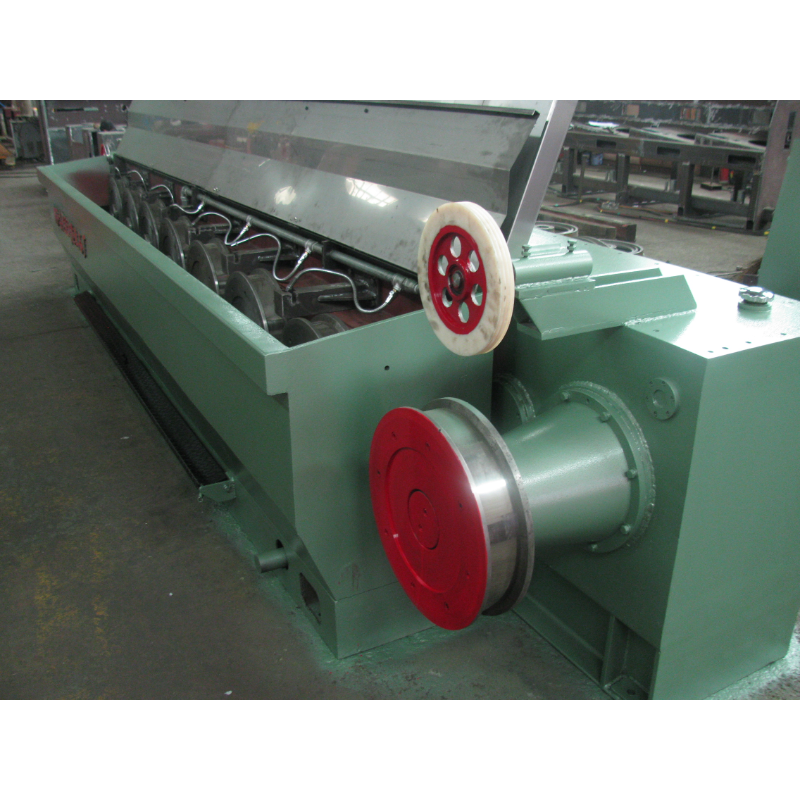

A standard rod breakdown drawing machine is a crucial piece of equipment in the wire and cable manufacturing industry. It is used to reduce the diameter of wire rods and draw them into various sizes of wire. To ensure the machine operates efficiently and effectively, regular maintenance is essential. In this article, we will discuss some maintenance tips for a Copper Wire Drawing Machine.

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, pulleys, and bearings. Replace any worn-out parts immediately to prevent further damage to the machine. Lubricate moving parts regularly to reduce friction and ensure smooth operation.

Another important maintenance tip is to clean the machine regularly. Dust, dirt, and debris can accumulate on the machine over time, causing it to malfunction. Use a soft brush or cloth to remove any buildup from the machine’s surfaces. Pay special attention to the wire guides and dies, as any debris in these areas can affect the quality of the drawn wire.

In addition to regular cleaning, it is important to calibrate the Copper Wire Drawing Machine for Rod Breakdown Machine periodically. Check the tension settings, speed controls, and other parameters to ensure they are set correctly. Improper calibration can lead to uneven wire drawing and poor quality wire. Consult the machine’s manual for specific calibration instructions and follow them carefully.

Regularly inspect the electrical components of the machine, such as the motor, control panel, and wiring. Look for any signs of damage or overheating, and replace any faulty components immediately. Keep the electrical components clean and free of dust to prevent electrical malfunctions.

It is also important to monitor the machine’s performance regularly. Keep track of the wire diameter, speed, and tension settings to ensure they are within the specified range. Any deviations from the standard parameters could indicate a problem with the machine that needs to be addressed.

In addition to regular maintenance, it is important to train operators on how to use the machine properly. Provide training on safety procedures, maintenance tasks, and troubleshooting techniques. Encourage operators to report any issues or concerns with the machine promptly to prevent further damage.

Lastly, consider scheduling routine maintenance checks with a qualified technician. A professional inspection can help identify any potential issues with the machine before they escalate into major problems. A technician can also provide recommendations for improving the machine’s performance and longevity.

In conclusion, regular maintenance is essential for ensuring the efficient operation of a standard rod breakdown drawing machine. By following these maintenance tips, you can prolong the life of the machine, improve wire quality, and prevent costly repairs. Remember to inspect, clean, calibrate, monitor, train, and schedule routine maintenance checks to keep your machine running smoothly.