Table of Contents

How to Choose the Right Water-Tank Wire Drawing Machine for Your Copper Wire Manufacturing Process

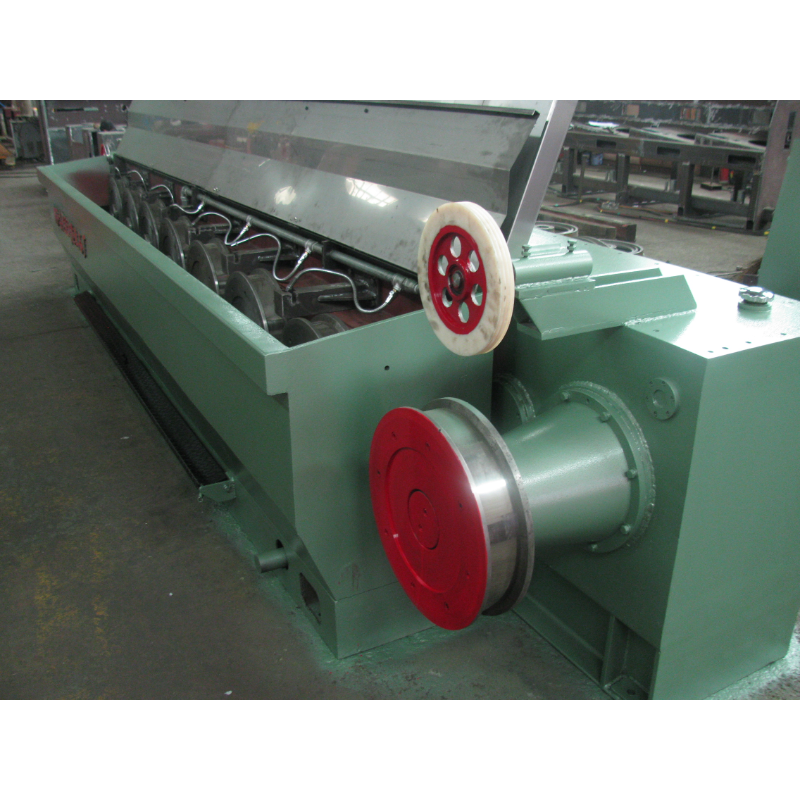

When it comes to manufacturing copper wire, one of the key pieces of equipment you will need is a water-tank wire drawing machine. This machine is essential for pulling the copper wire through a series of dies to reduce its diameter and improve its quality. However, with so many options available on the market, choosing the right water-tank wire drawing machine can be a daunting task. In this article, we will discuss some important factors to consider when selecting a water-tank wire drawing machine for your copper wire manufacturing process.

First and foremost, you need to consider the size and capacity of the machine. The size of the machine will depend on the volume of copper wire you plan to produce. If you have a high production capacity, you will need a larger machine with multiple drawing dies to ensure efficient and continuous operation. On the other hand, if you have a smaller production volume, a smaller machine with fewer drawing dies may be sufficient.

Another important factor to consider is the speed and efficiency of the machine. A Copper Wire Drawing Machine with a high drawing speed will allow you to produce more copper wire in a shorter amount of time. Additionally, a machine with high efficiency will minimize waste and reduce production costs. Therefore, it is important to choose a machine that offers a good balance between speed and efficiency to maximize productivity.

In addition to size and speed, you should also consider the quality of the machine. Look for a water-tank wire drawing machine that is made from high-quality materials and is built to last. A durable machine will require less maintenance and repair, saving you time and money in the long run. Additionally, a high-quality machine will produce copper wire of superior quality, which is essential for meeting the standards of your customers.

Furthermore, consider the versatility of the machine. A water-tank wire drawing machine that can accommodate a wide range of wire diameters will allow you to produce different types of copper wire for various applications. This versatility will give you the flexibility to adapt to changing market demands and expand your product offerings.

When choosing a water-tank wire drawing machine, it is also important to consider the reputation of the manufacturer. Look for a reputable company with a proven track record of producing high-quality wire drawing machines. Reading customer reviews and testimonials can help you gauge the reliability and performance of the machine before making a purchase.

Lastly, consider the cost of the machine. While it is important to invest in a high-quality water-tank wire drawing machine, you should also consider your budget constraints. Compare prices from different manufacturers and choose a machine that offers the best value for your money.

In conclusion, choosing the right water-tank wire drawing machine for your copper wire manufacturing process is crucial for achieving high-quality and efficient production. Consider factors such as size, speed, efficiency, quality, versatility, manufacturer reputation, and cost when making your decision. By taking the time to research and evaluate your options, you can select a machine that meets your specific needs and helps you achieve success in the copper wire industry.

Benefits of Using a Water-Tank Wire Drawing Machine For Copper Wire Production

Copper wire is a versatile material that is used in a wide range of industries, from electronics to construction. To meet the demand for high-quality copper wire, manufacturers rely on wire drawing machines to produce wire of various diameters. One type of wire drawing machine that is commonly used in the production of copper wire is the water-tank wire drawing machine.

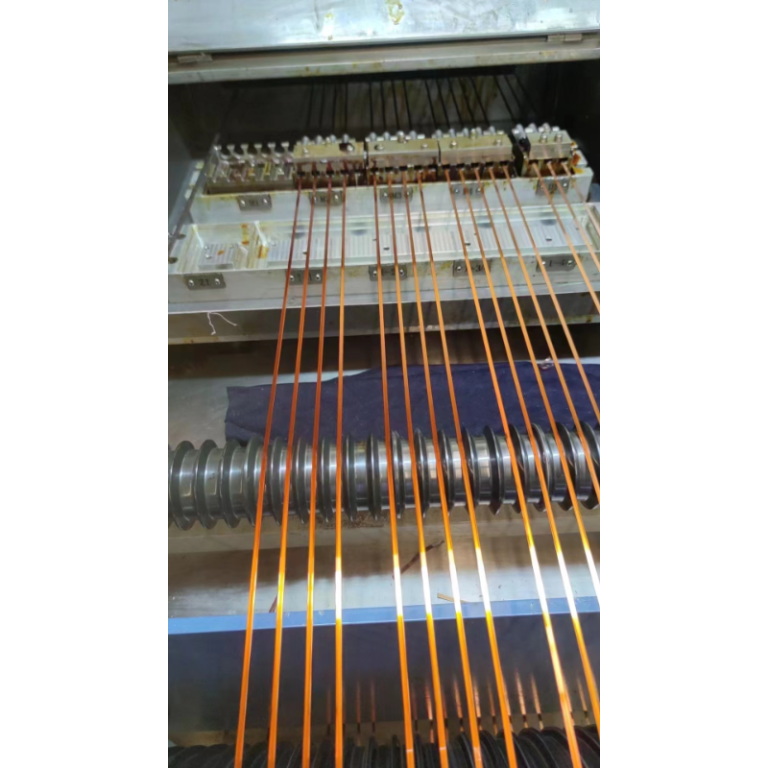

The Wet Type Drawing Machines For Copper Wire is a specialized piece of equipment that offers several benefits for copper wire production. One of the key advantages of using a water-tank wire drawing machine is its ability to cool the wire during the drawing process. As the wire is pulled through the die, it generates heat due to friction. If the wire becomes too hot, it can become brittle and prone to breakage. By immersing the wire in a water tank during the drawing process, the machine helps to dissipate heat and maintain the wire’s structural integrity.

In addition to cooling the wire, the water-tank wire drawing machine also helps to lubricate the wire as it passes through the die. Lubrication is essential for reducing friction and preventing the wire from sticking to the die, which can cause defects in the finished product. The water in the tank acts as a natural lubricant, ensuring smooth and consistent drawing of the wire.

Another benefit of using a water-tank wire drawing machine for copper wire production is its ability to control the speed of the drawing process. The machine is equipped with adjustable speed settings, allowing operators to fine-tune the drawing speed to meet the specific requirements of the wire being produced. This level of control helps to ensure that the wire is drawn at the optimal speed for achieving the desired diameter and quality.

Furthermore, the water-tank wire drawing machine is designed to minimize downtime and maximize productivity. The machine is equipped with a continuous wire feeding system that allows for uninterrupted operation, reducing the need for frequent stops and starts. This not only increases efficiency but also helps to reduce waste and improve overall production output.

In conclusion, the water-tank wire drawing machine offers several benefits for copper wire production. From cooling and lubricating the wire to controlling drawing speed and minimizing downtime, this specialized piece of equipment plays a crucial role in ensuring the quality and consistency of copper wire products. Manufacturers looking to enhance their wire drawing processes and improve overall efficiency should consider investing in a water-tank wire drawing machine. With its advanced features and capabilities, this machine is a valuable asset for any copper wire production facility.