Advantages of Using Wet Type Drawing Machines For Aluminum Wire

Wet type drawing machines are a crucial tool in the manufacturing process of aluminum wire. These machines are specifically designed to draw aluminum wire through a series of dies to reduce its diameter and improve its mechanical properties. There are several advantages to using wet type drawing machines for aluminum wire, which make them a preferred choice for many manufacturers in the industry.

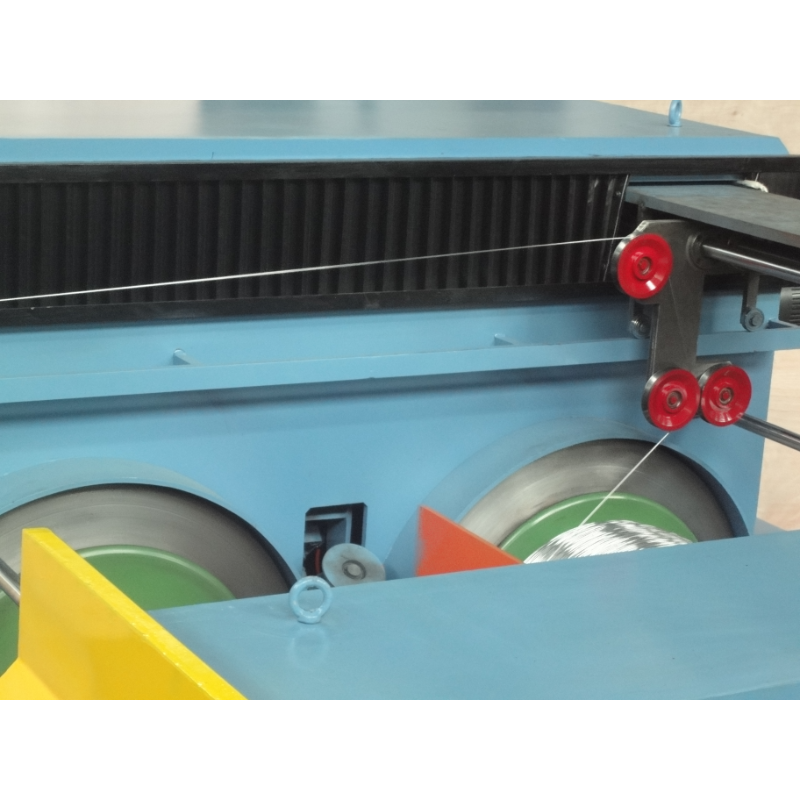

One of the primary advantages of wet type drawing machines is their ability to improve the surface quality of the aluminum wire. The wet drawing process involves using a lubricant or coolant to reduce friction between the wire and the dies, resulting in a smoother surface finish. This is essential for applications where the appearance of the wire is important, such as in the production of electrical cables or automotive components.

In addition to improving surface quality, wet type drawing machines also help to enhance the mechanical properties of the aluminum wire. The lubricant or coolant used in the drawing process helps to reduce the risk of surface defects and cracks, resulting in a stronger and more durable wire. This is particularly important for applications where the wire will be subjected to high levels of stress or strain, such as in the construction industry.

Another advantage of using wet type drawing machines for Aluminum Wire Making Machine is their ability to increase productivity and efficiency in the manufacturing process. The lubricant or coolant used in the drawing process helps to reduce heat generation and wear on the dies, allowing for faster drawing speeds and longer die life. This means that manufacturers can produce more wire in less time, leading to cost savings and improved overall efficiency.

Furthermore, wet type drawing machines are also more environmentally friendly compared to dry drawing machines. The use of lubricants or coolants in the drawing process helps to reduce the amount of energy required to draw the wire, as well as the amount of waste generated during the manufacturing process. This makes wet type drawing machines a more sustainable option for manufacturers looking to reduce their environmental impact.

Overall, wet type drawing machines offer a range of advantages for manufacturers in the aluminum wire industry. From improving surface quality and mechanical properties to increasing productivity and efficiency, these machines are a valuable tool for producing high-quality aluminum wire for a variety of applications. With their ability to enhance the manufacturing process and reduce environmental impact, wet type drawing machines are a preferred choice for many manufacturers looking to stay competitive in the industry.