Table of Contents

How to Optimize Efficiency and Quality in Automatic Enameling Wire Production Line Operations

In the world of manufacturing, efficiency and quality are two key factors that can make or break a business. This is especially true in the production of enameling wire, where precision and consistency are essential for creating a product that meets the high standards of the industry. One way to optimize efficiency and quality in Enameling Machine is through the use of automatic production lines.

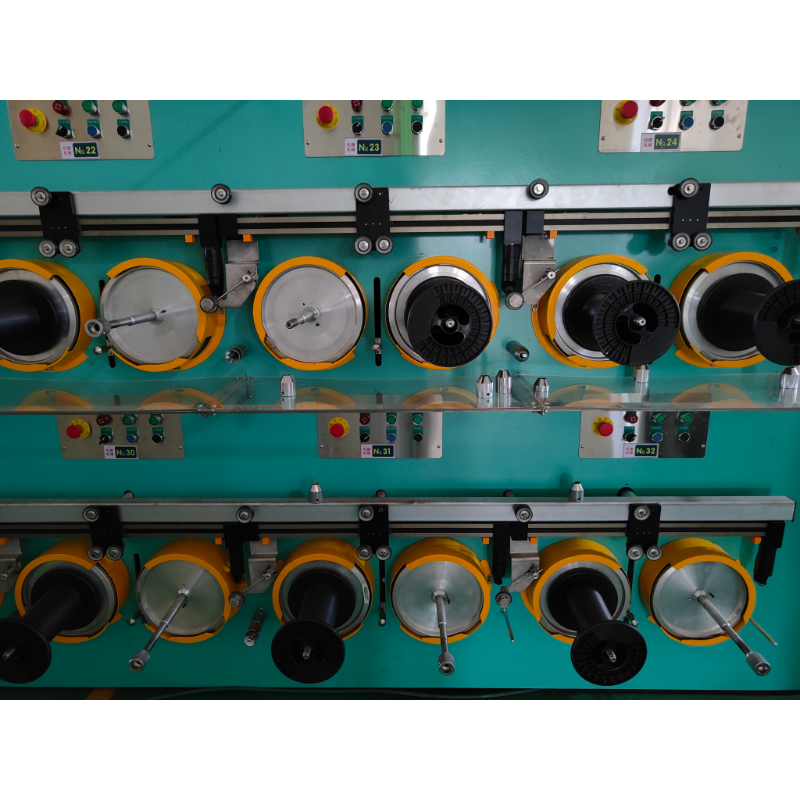

Automatic enameling wire production lines are designed to streamline the manufacturing process, reducing the need for manual labor and increasing output. These production lines are equipped with advanced machinery and technology that can perform tasks such as wire drawing, enameling, drying, and cooling with precision and speed. By automating these processes, manufacturers can achieve higher levels of efficiency and consistency in their production operations.

One of the key benefits of using an automatic A Type Air Recirculation Enameling Machine is the ability to optimize production efficiency. These production lines are designed to operate continuously, with minimal downtime between production runs. This means that manufacturers can produce larger quantities of enameling wire in a shorter amount of time, increasing overall output and reducing production costs. Additionally, automatic production lines can be programmed to perform tasks with a high degree of accuracy, ensuring that each batch of wire meets the required specifications.

In addition to improving efficiency, automatic enameling wire production lines can also enhance the quality of the finished product. By automating the production process, manufacturers can reduce the risk of human error and inconsistencies that can occur with manual labor. This results in a more uniform and consistent product that meets the high standards of the industry. Automatic production lines can also be equipped with quality control systems that monitor the production process in real-time, allowing manufacturers to quickly identify and address any issues that may arise.

To further optimize efficiency and quality in automatic enameling wire production line operations, manufacturers can implement a number of best practices. One important factor to consider is the maintenance of the production line equipment. Regular maintenance and calibration of machinery can help prevent breakdowns and ensure that the production line operates at peak efficiency. Manufacturers should also invest in training for their employees to ensure that they are familiar with the operation of the automatic production line and can troubleshoot any issues that may arise.

Another key aspect of optimizing efficiency and quality in automatic enameling wire production line operations is the use of advanced technology. Manufacturers should consider investing in the latest machinery and equipment that can improve the speed and accuracy of the production process. This may include automated wire drawing machines, high-speed enameling equipment, and advanced cooling systems. By staying up-to-date with the latest technology, manufacturers can ensure that their production line remains competitive in the industry.

In conclusion, automatic enameling wire production lines offer manufacturers a way to optimize efficiency and quality in their production operations. By automating the manufacturing process, manufacturers can increase output, reduce costs, and improve the consistency of their products. By implementing best practices and investing in advanced technology, manufacturers can further enhance the efficiency and quality of their automatic production line operations. Ultimately, by focusing on efficiency and quality, manufacturers can position themselves for success in the competitive enameling wire industry.

Benefits of Implementing an Automatic Enameling Wire Production Line

In today’s fast-paced manufacturing industry, efficiency and productivity are key factors in staying competitive. One way to streamline the production process and increase output is by implementing an automatic Enameling Coating Machine. This advanced technology offers a range of benefits that can significantly improve the overall performance of a manufacturing operation.

One of the primary advantages of an automatic enameling wire production line is the increase in production speed. By automating the process of applying enamel coating to wire, manufacturers can significantly reduce the time it takes to complete each batch. This not only allows for higher output levels but also ensures a consistent and uniform coating on each wire, resulting in a higher quality end product.

In addition to speed, automatic enameling wire production lines also offer improved accuracy and precision. The automated machinery is programmed to apply the enamel coating with exact measurements, ensuring that each wire meets the required specifications. This level of precision is difficult to achieve with manual processes, where human error can lead to inconsistencies in the coating thickness or quality.

Furthermore, automatic enameling wire production lines are designed to minimize waste and reduce material costs. The machinery is optimized to use the enamel coating efficiently, ensuring that only the necessary amount is applied to each wire. This not only helps to reduce the overall cost of production but also contributes to a more sustainable manufacturing process by minimizing the amount of waste generated.

Another key benefit of implementing an automatic enameling wire production line is the reduction in labor costs. By automating the enameling process, manufacturers can significantly reduce the number of workers required to operate the machinery. This not only saves on labor expenses but also frees up employees to focus on other tasks within the manufacturing operation, further increasing overall efficiency.

Additionally, automatic enameling wire production lines offer improved safety features compared to manual processes. The machinery is equipped with advanced sensors and safety mechanisms to prevent accidents and ensure a safe working environment for employees. This not only protects workers from potential hazards but also reduces the risk of costly downtime due to injuries or accidents.

Overall, the implementation of an automatic enameling wire production line can have a transformative impact on a manufacturing operation. From increased production speed and accuracy to reduced waste and labor costs, the benefits of this advanced technology are clear. By investing in automation, manufacturers can improve efficiency, quality, and safety, ultimately leading to a more competitive and successful business.