Table of Contents

Common Challenges Faced in Aluminum Wire Drawing Process Operations

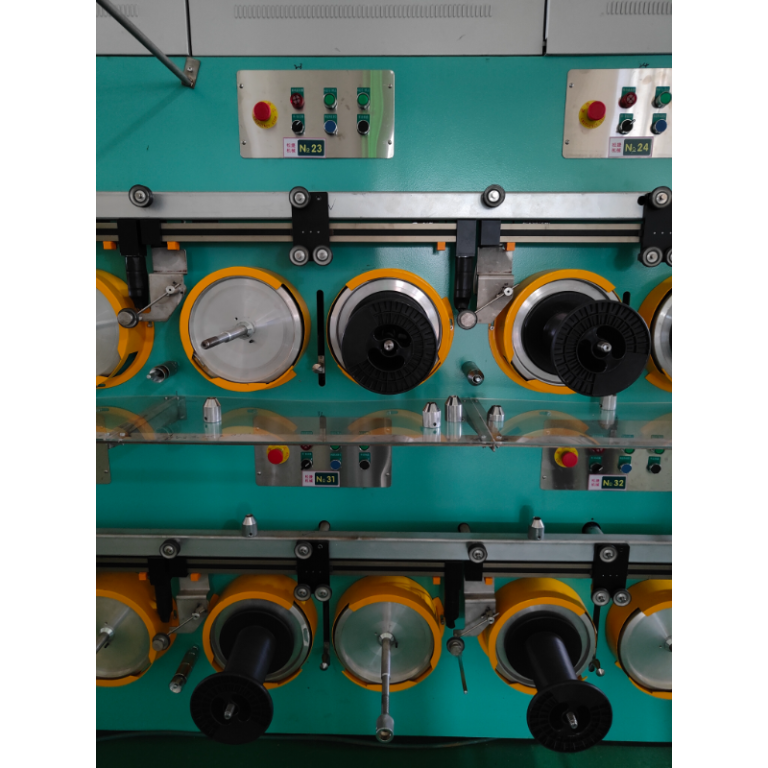

Aluminium wire drawing is a process used to reduce the diameter of aluminum wire by pulling it through a series of dies. This process is essential in the production of various aluminium products, such as electrical wiring, cables, and conductors. However, like any manufacturing process, aluminium wire drawing comes with its own set of challenges that can impact the quality and efficiency of the operation.

One common challenge faced in aluminum wire drawing operations is die wear. As the wire is pulled through the dies, friction and pressure cause the dies to wear down over time. This can result in an increase in wire breakage, surface defects, and dimensional inaccuracies. To mitigate this challenge, regular maintenance and inspection of the dies are essential. Additionally, using high-quality dies made from materials with high wear resistance can help prolong their lifespan.

Another challenge in Aluminum Wire Breakdown Machine is surface quality. The surface of the wire can be affected by various factors, such as die wear, lubrication, and drawing speed. Poor surface quality can lead to issues like surface defects, roughness, and reduced conductivity. To improve surface quality, it is important to use proper lubrication during the drawing process and ensure that the dies are in good condition. Adjusting the drawing speed and tension can also help achieve a smoother surface finish.

Dimensional accuracy is another critical aspect of aluminium wire drawing. Variations in wire diameter can impact the performance and functionality of the final product. Factors like die wear, material properties, and drawing parameters can affect dimensional accuracy. To address this challenge, it is important to monitor and control the drawing parameters, such as die size, reduction ratio, and drawing speed. Regular calibration of equipment and dies can also help maintain dimensional accuracy throughout the drawing process.

One of the most significant challenges in aluminium wire drawing is material properties. Aluminum is a soft and ductile metal, which can make it prone to deformation and breakage during the drawing process. Controlling the material properties, such as alloy composition, grain size, and microstructure, is crucial to achieving consistent and high-quality wire. Proper heat treatment and annealing processes can help improve the mechanical properties of the aluminium wire, making it more suitable for drawing operations.

In conclusion, aluminum wire drawing operations face several common challenges that can impact the quality and efficiency of the process. Die wear, surface quality, dimensional accuracy, and material properties are key factors that need to be carefully managed to ensure successful wire drawing operations. By addressing these challenges through proper maintenance, control of drawing parameters, and material optimization, manufacturers can produce high-quality aluminium wire for various applications. Continuous improvement and innovation in the wire drawing process are essential to overcome these challenges and meet the demands of the industry.

Advantages of Using Aluminum Wire in the Drawing Process

Aluminum wire drawing is a process that involves pulling a metal wire through a series of dies to reduce its diameter and increase its length. This process is commonly used in the manufacturing of electrical wiring, cables, and various other products that require a thin and flexible metal wire. While copper has traditionally been the preferred material for wire drawing due to its excellent conductivity, aluminum is gaining popularity as a viable alternative.

One of the main advantages of using Aluminum Sheet Wire Drawing Machine in the drawing process is its lightweight nature. Aluminum is significantly lighter than copper, making it easier to handle and transport. This can result in cost savings for manufacturers, as lighter materials require less energy to produce and ship. Additionally, the lightweight nature of aluminium wire makes it ideal for applications where weight is a concern, such as in aerospace and automotive industries.

Another advantage of using aluminum wire in the drawing process is its excellent conductivity. While copper is known for its high conductivity, aluminum is not far behind. In fact, aluminum has approximately 61% of the conductivity of copper, making it a suitable alternative for many applications. This high conductivity allows aluminum wire to efficiently transmit electricity, making it a reliable choice for electrical wiring and other applications where conductivity is crucial.

In addition to its lightweight nature and excellent conductivity, aluminum wire also offers superior corrosion resistance. Unlike copper, which is prone to corrosion over time, aluminum is highly resistant to rust and other forms of corrosion. This makes aluminum wire a durable and long-lasting option for applications where exposure to moisture or harsh environments is a concern. Additionally, the corrosion resistance of aluminum wire can help extend the lifespan of products and reduce maintenance costs over time.

Furthermore, aluminum wire is more cost-effective than copper, making it an attractive option for manufacturers looking to reduce production costs. The price of aluminium is typically lower than that of copper, making it a more affordable material for wire drawing processes. Additionally, the lightweight nature of aluminium wire can result in lower shipping costs, further contributing to overall cost savings for manufacturers.

Despite its many advantages, there are some limitations to using aluminum wire in the drawing process. One of the main drawbacks is its lower tensile strength compared to copper. This means that aluminum wire may not be as strong or durable as copper wire, making it less suitable for applications where high tensile strength is required. However, advancements in metallurgy and manufacturing processes have led to the development of high-strength aluminum alloys that can rival the tensile strength of copper.

In conclusion, the advantages of using aluminum wire in the drawing process make it a viable alternative to copper for many applications. Its lightweight nature, excellent conductivity, corrosion resistance, and cost-effectiveness make it an attractive option for manufacturers looking to reduce production costs and improve product performance. While there are some limitations to using aluminum wire, ongoing research and development efforts are continuously improving the strength and durability of aluminium alloys, making them a competitive choice for a wide range of applications.