Table of Contents

How to Choose the Right Enameling Machine for Your Business

Enameling machines are essential tools for businesses that work with metal surfaces and want to add a durable and attractive finish to their products. Choosing the right enameling machine for your business is crucial to ensure that you achieve the desired results efficiently and effectively. There are several factors to consider when selecting an enameling machine, including the type of enamel you will be using, the size and shape of your products, and your production volume.

One of the first things to consider when choosing an enameling machine is the type of enamel you will be using. There are different types of enamels available, including wet enamel, powder enamel, and electrostatic enamel. Each type of enamel requires a specific type of enameling machine to apply it correctly. Wet enamel, for example, is typically applied using a spray gun, while powder enamel is often applied using a powder coating machine. Electrostatic enamel, on the other hand, requires a specialized electrostatic enameling machine. It is essential to choose an enameling machine that is compatible with the type of enamel you will be using to ensure that you achieve the best results.

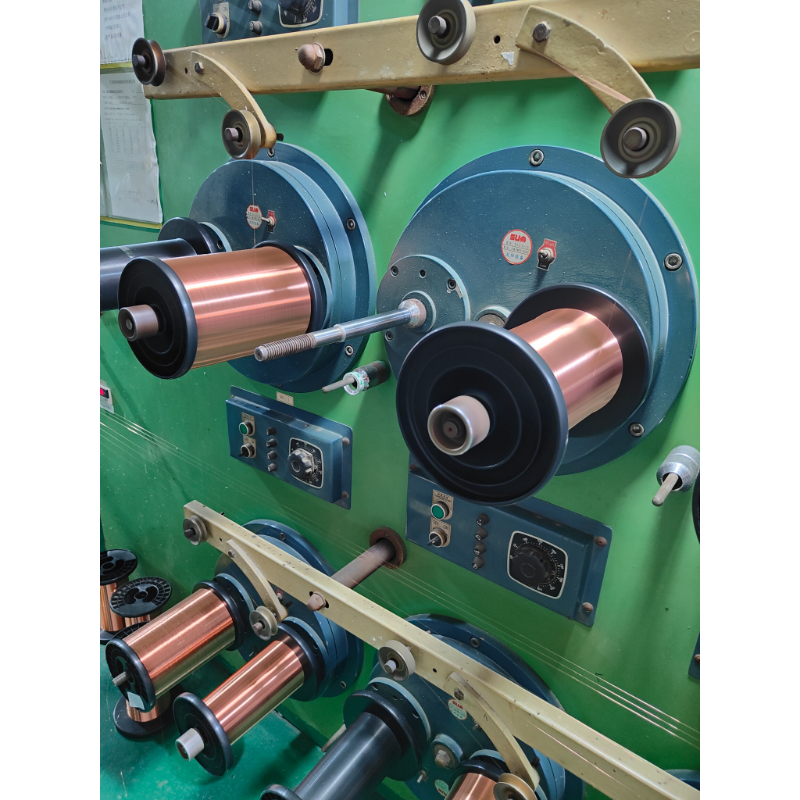

Another important factor to consider when choosing a wire enameling machine is the size and shape of your products. Enameling machines come in a variety of sizes and configurations, so it is essential to choose a machine that can accommodate the size and shape of your products. If you are working with small, intricate pieces, you may need a smaller enameling machine with precise control over the application of the enamel. If you are working with larger products, you may need a larger enameling machine with a larger working area. It is crucial to choose a machine that can handle the size and shape of your products to ensure that you achieve consistent and high-quality results.

In addition to the size and shape of your products, you should also consider your production volume when choosing an enameling machine. If you have a high production volume, you will need a machine that can keep up with the demand and provide fast and efficient enameling. Look for a machine that offers high-speed enameling and quick changeover times to minimize downtime and maximize productivity. If you have a lower production volume, you may be able to choose a smaller machine with slower speeds that can still meet your needs without overinvesting in unnecessary features.

When choosing an enameling machine for your business, it is essential to consider the type of enamel you will be using, the size and shape of your products, and your production volume. By taking these factors into account, you can choose a machine that will help you achieve the desired results efficiently and effectively. Whether you are working with wet enamel, powder enamel, or electrostatic enamel, there is an enameling machine available to meet your needs. Take the time to research your options and choose a machine that will help you take your business to the next level with high-quality enameling.

Maintenance Tips for Ensuring Longevity of Enameling Machines

Enameling machines are essential tools in the manufacturing industry, used for applying a protective coating of enamel to various metal products. These machines are intricate pieces of equipment that require regular maintenance to ensure their longevity and optimal performance. By following a few simple maintenance tips, you can keep your enameling machine running smoothly for years to come.

One of the most important maintenance tasks for enameling machines is regular cleaning. Over time, enamel residue can build up on the machine’s components, leading to decreased efficiency and potential damage. To prevent this buildup, it is essential to clean the machine thoroughly after each use. Use a soft brush or cloth to remove any excess enamel from the machine’s surfaces, paying particular attention to areas where enamel tends to accumulate, such as the nozzles and rollers.

In addition to regular cleaning, it is crucial to inspect the machine for any signs of wear or damage. Check the machine’s rollers, nozzles, and other components for any cracks, dents, or other issues that could affect its performance. If you notice any damage, it is essential to address it promptly to prevent further problems. Replace any worn or damaged parts as needed to keep the machine in optimal working condition.

Another important maintenance tip for Enameling Wire Production Line is to lubricate the machine’s moving parts regularly. Proper lubrication helps reduce friction and wear on the machine’s components, extending its lifespan and ensuring smooth operation. Use a high-quality lubricant recommended by the machine’s manufacturer and follow the manufacturer’s guidelines for lubrication frequency and application.

In addition to regular cleaning and lubrication, it is essential to calibrate the machine regularly to ensure accurate enamel application. Improper calibration can lead to uneven coating thickness and other issues that can affect the quality of the finished product. Follow the manufacturer’s guidelines for calibration and make any necessary adjustments to ensure the machine is operating correctly.

Finally, it is essential to store the enameling machine properly when not in use. Store the machine in a clean, dry environment away from dust, moisture, and other contaminants that could damage its components. Cover the machine with a protective cover when not in use to prevent dust and debris from accumulating on its surfaces.

In conclusion, regular maintenance is essential for ensuring the longevity and optimal performance of enameling machines. By following these maintenance tips, you can keep your machine running smoothly for years to come. Remember to clean the machine regularly, inspect it for damage, lubricate its moving parts, calibrate it as needed, and store it properly when not in use. With proper maintenance, your enameling machine will continue to produce high-quality enamel-coated products for years to come.

Benefits of Using Enameling Machines in Industrial Applications

Enameling machines have become an essential tool in various industrial applications due to their efficiency and effectiveness in applying enamel coatings to a wide range of products. These machines offer numerous benefits that make them a valuable asset for businesses looking to improve their production processes and enhance the quality of their products.

One of the key advantages of using enameling machines is their ability to apply enamel coatings quickly and evenly, resulting in a smooth and uniform finish. This is particularly important in industries such as automotive, aerospace, and electronics, where the quality of the coating can have a significant impact on the performance and durability of the final product. Enameling machines are designed to ensure that the enamel is applied consistently across the entire surface of the product, eliminating the risk of uneven coverage or missed spots.

In addition to providing a high-quality finish, enameling machines also offer increased efficiency and productivity compared to manual application methods. These machines are capable of applying enamel coatings at a much faster rate than traditional methods, allowing businesses to increase their production output and meet tight deadlines more effectively. This can help companies reduce lead times, improve customer satisfaction, and ultimately boost their bottom line.

Furthermore, enameling machines are designed to be user-friendly and easy to operate, making them suitable for a wide range of industries and applications. Many modern enameling machines come equipped with advanced features such as programmable settings, automatic controls, and digital displays, allowing operators to adjust the machine settings quickly and accurately to achieve the desired results. This not only saves time and labor costs but also reduces the risk of human error and ensures consistent quality across all products.

Another significant benefit of using enameling machines is their versatility and adaptability to different types of products and materials. These machines can be customized to accommodate various shapes, sizes, and materials, making them suitable for a wide range of applications, from small electronic components to large industrial equipment. This flexibility allows businesses to streamline their production processes, reduce setup times, and increase overall efficiency.

Moreover, enameling machines are designed to be durable and reliable, ensuring long-term performance and minimal maintenance requirements. These machines are built to withstand the rigors of industrial use, with robust construction and high-quality components that can withstand heavy-duty operation and frequent use. This makes them a cost-effective investment for businesses looking to improve their production processes and enhance the quality of their products.

In conclusion, enameling machines offer numerous benefits for businesses in various industries, from automotive and aerospace to electronics and manufacturing. These machines provide a high-quality finish, increased efficiency, productivity, and versatility, making them an essential tool for companies looking to improve their production processes and enhance the quality of their products. With their user-friendly design, advanced features, and durable construction, enameling machines are a valuable asset that can help businesses stay competitive in today’s fast-paced market.